The boxford vertical slide is a bit different to others as is the boring table. Both fit in place of the compound slide which I feel limits their use more than you might suspect. They did it this way because most of their lathes apart from an ME10 don't have a T Slotted cross slide.

It is possible to fit a T slotted cross slide to all of them via this man who is so busy it can be hard to get hold of him.

**LINK**

He will also make T slotted cross slides for some other lathes.

This still leaves the vertical slide as a bit of a problem. The best option is probably a Myford one that might benefit from packing up to account for the difference in centre height over the cross slide.

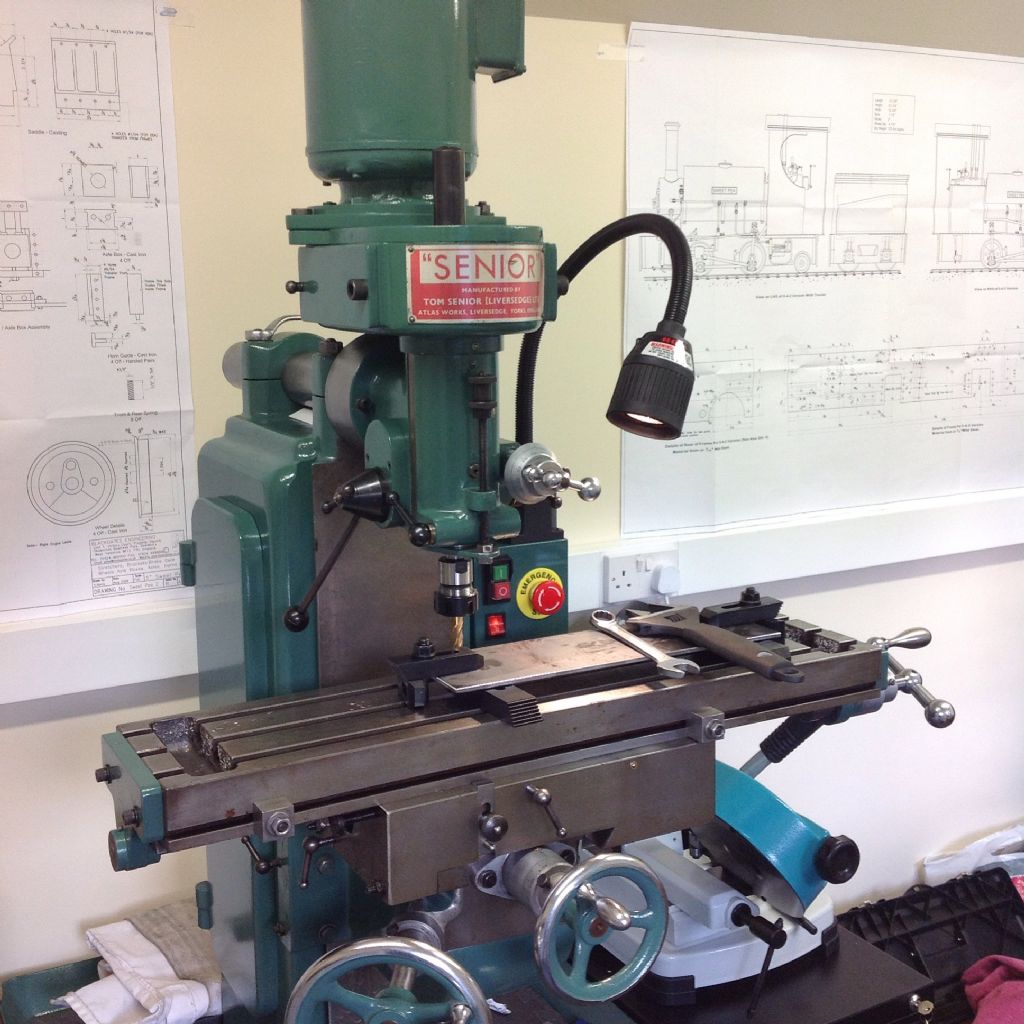

I'd go along with others. A separate miller is the best option really. In general the only use I make of the T slotted cross slide on my ME10 is for a slotting attachment. Mainly for keyways. It's based on castings intended for Myfords as many things are. Easily remedied by fitting an aluminium plate under the casting to increase the centre height.

I feel you have made a good choice in lathes. If you need help understanding it, parts and etc I would suggest you join the yahoo boxford group. There are plenty of people on there with detailed knowledge of the lathe. Also parts lists and other bits and pieces.

I've owned a number of makes of lathe and to be honest the Boxford has been the least trouble of the lot. I might be lucky in terms of lack of bed wear but they are a well put together piece of kit.

I've owned a number of makes of lathe and to be honest the Boxford has been the least trouble of the lot. I might be lucky in terms of lack of bed wear but they are a well put together piece of kit.

John

–

Ajohnw.