Emgee

That’s good enough for me I’ll more than likely get the 5.5 – 8.0 amp NVR unit shown.

Incidentally I’m still awaiting a reply from Axminster Tools.

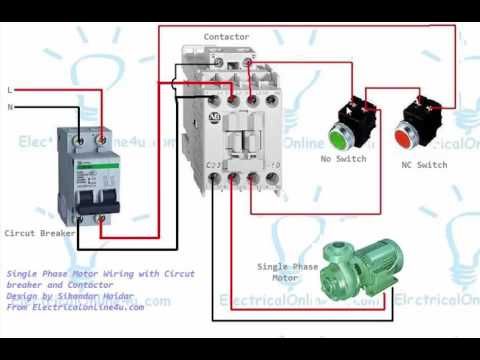

I’ve been having a look at a Motor Water Proof Machine Drill Switch ON/OFF Push Button for 10A 220/380V £5.69 (item No: 143265824264) on ebay or same thing on amazon TOOGOO(R) AC 220/380V On/Off Water Proof Push Button Switch KAO-5 for Drill Motor Machine £3.29

Would it be possible to wire either of the above switches in circuit with the NVR unit or would it be a case of once the machine has been switched off by any of the stop buttons the only way it can be restarted is via the start button on the NVR unit, I’m guessing that is what the case will be, any ideas??

If it can only be restarted by the NVR unit I may as well buy the GLOGLOW 660V 10A Emergency Stop Switch £6.89 on amazon or 10A 660V Red Sign Mushroom Emergency Stop Push Button Switch Station Yellow XKUK £5.48 on ebay item No: 133115256527.

I assume 660V will also be good to go on 230V??

Thanks again for any advice you can give

Clive

Clive B 1.