Already hot so I've been looking carefully at the all the answers before having another go.

I haven't got to the drilling part of the problem yet, so ways of minimising that are of interest. Tony Pratt suggested not drilling all the way through, but that opens the door to other problems. The joint has to take the weight of the bob and I don't know how long the superglued joint needs to be to take the weight. Not much, my bob is only about 20g. The other issue is the long sleeve stops the rod bending inside the bob, but there are other ways of doing that. I might experiment with the strength of superglue joints later.

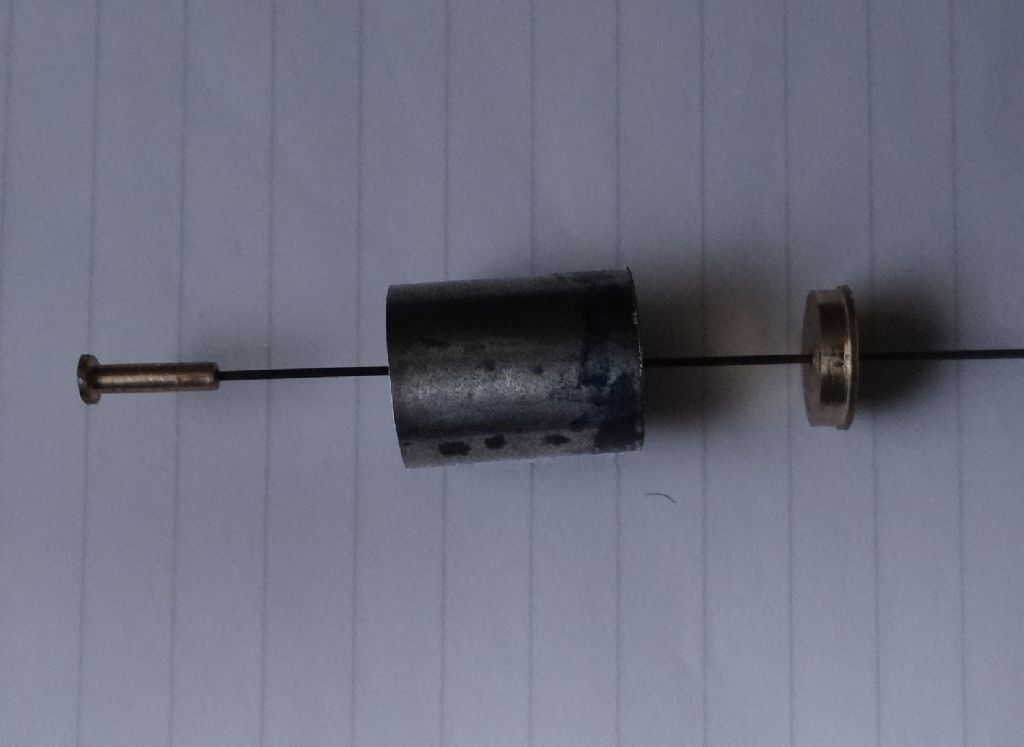

Duncan's suggestion (and others) of filling the 2.5mm hole is only unattractive because I didn't mention I want to experiment suspending the bob with Carbon rods 0.28mm, 0.5mm, 0.8mm, 1.0mm and 1.5mm: ideally the set-up shouldn't be permanent,

Simon's jewellery suggestion and Michaels link to watchmaker technique are both worth following up. Other disciplines like jewellery, gun-smithing, and horology have much to offer.

Assuming I ever get a 0.3mm diameter rod, the drill form would be as suggested by Hopper. John Carruthers' modified needle is interesting; I don't think sewing needles go that small, but hypodermic needles do.

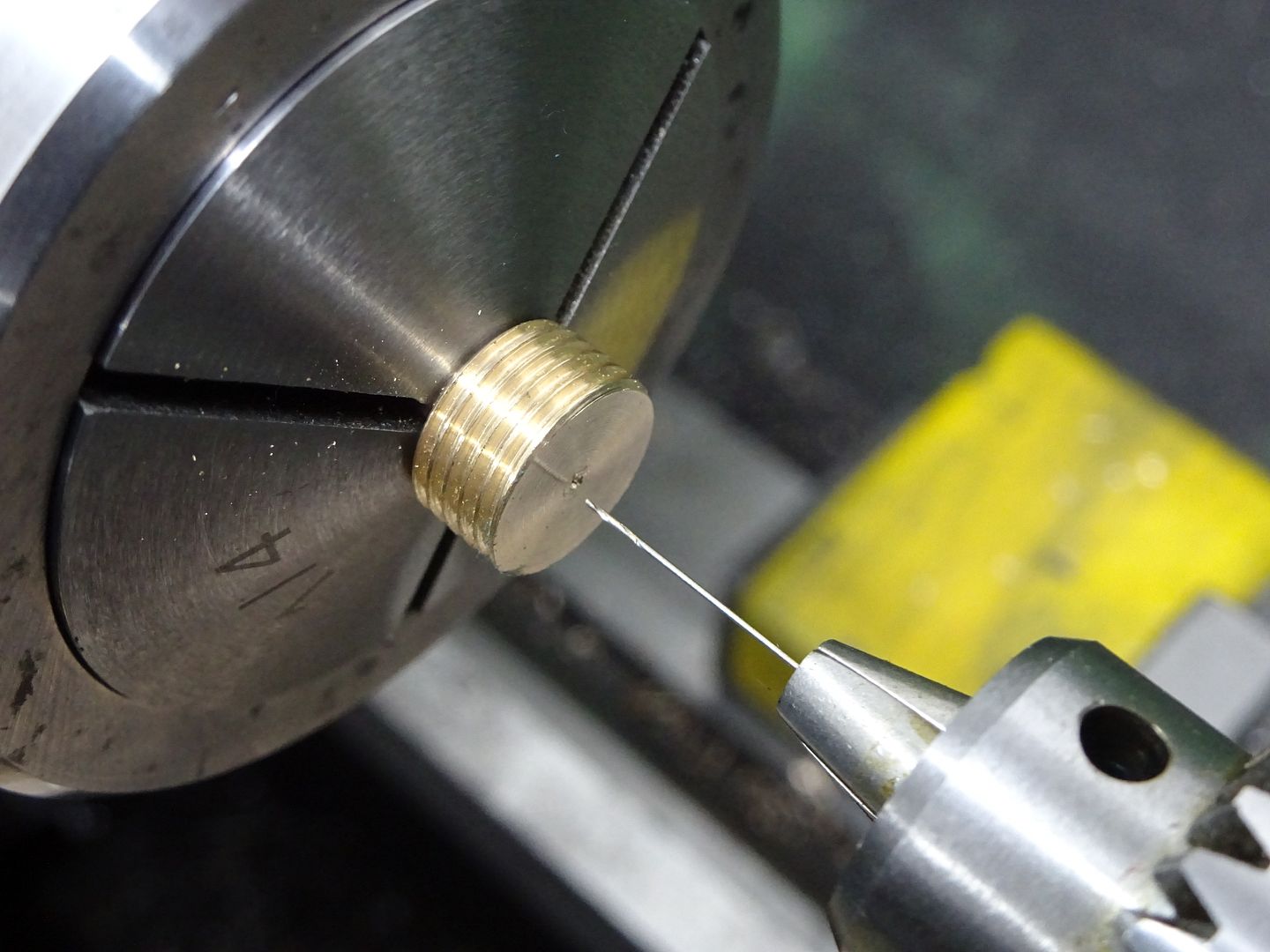

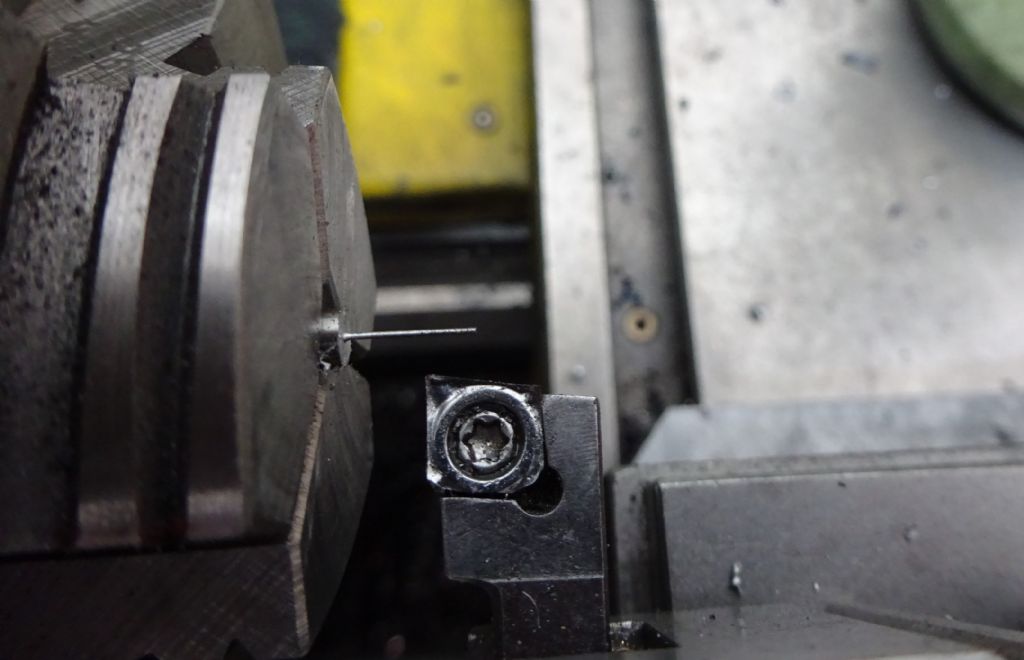

Lots to think about and try. For the moment I'm going to stick with turning down Silver Steel – if Jason can do it, so can I.

However, Jason said "Main thing is not to pussy foot about". Well, I was pussy footing. I had the idea that repeatedly shaving tiny amounts of metal off would stress a thin rod less than attacking it brutally. That's probably wrong because shaving makes the rod progressively weaker over it's full length and more likely to kink. An aggressive cut should bear against more metal at the cutting point to support the stress, leaving the turned down part relatively unpressured. Be interesting to see how I get on with a few heavy cuts. The metal surface of my failed first attempt (photo earlier in thread) looks as if there was more rubbing than cutting.

Dave

Michael Gilligan.

Michael Gilligan.