That lathe appears to be identical to my Model B No8 except for the geared headstock, All the lower bed etc is identical.

This is a superb lathe, I rarely use it these days but this morning I utilised the indexing bullwheel to file a square lug for a chuck key, the original locking pin tool is with mine as is the oil dropper in the tailstock and these are often missing on secondhand machines.

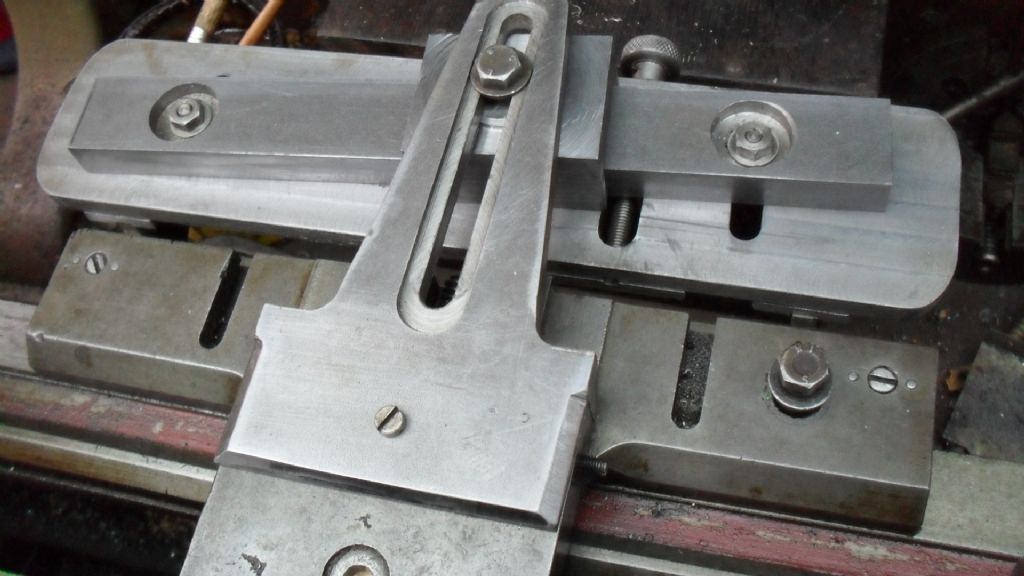

I have the original rotating collet stand with some ( rather poor) collets, original Oak box for the gears, original traveling and fixed steadies, original concentric toolpost, original backplates for the chucks etc.

I went to see Richard Anderson in Rugby about 30 years ago, having worked there he bought the rights to Holbrook and had many original blueprints etc. The number of my Lathe is 5554 with initials ET, he told me that was final inspector Eric Transmere in 1942 .He told me that the top of the cabinet ,whether it was the Oak or cast Iron version, was machined as a precision faceplate.

He printed me a copy of the model B owners manual whilst I was there.

vic newey.

vic newey.