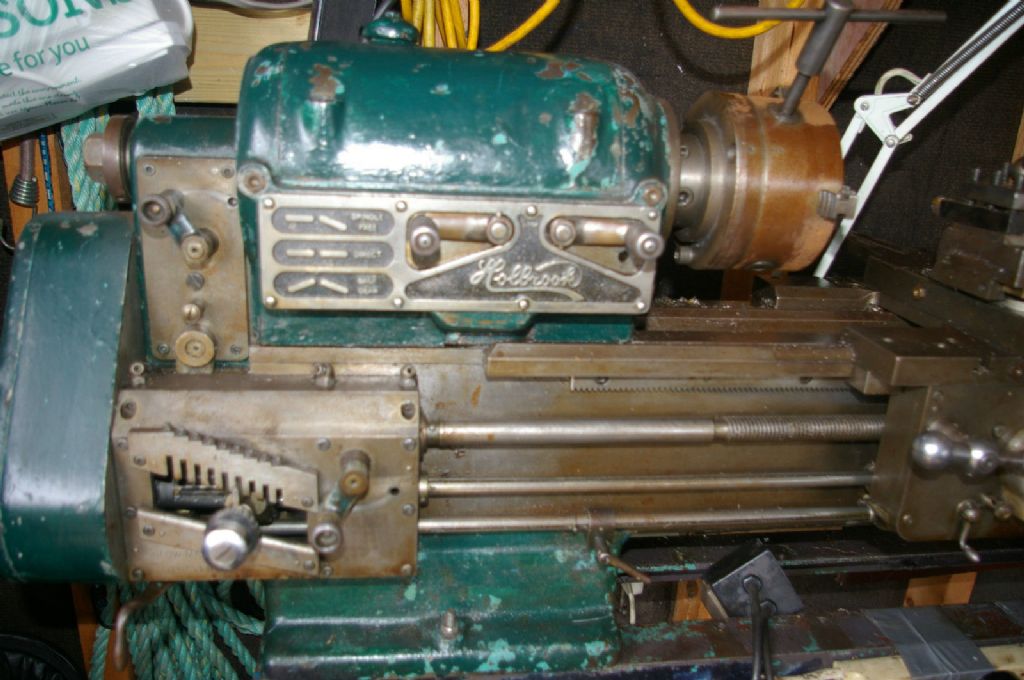

To add to my 1940s CovMac, a large lathe, I have this week fortuitously acquired a little one, from the same era – a Holbrook Model B No.8 Toolroom lathe.

A little beauty, with taper turning, it is presently lacking its pulley cone gear and counter-shaft. I would ideally like to connect with another owner, (or somebody with knowledge of this model), so that I can work out what it needs to complete these areas. I am just to be guessing at present. There is some remainder of counter-shaft arrangements on the back of the headstock. At present it only has, effectively, a single gear, running off the motor, its top speed of 1320 rpm. For its age, I would say it is in pretty remarkable condition. Very little needs doing to it, apart from cleaning, one or two lever knobs replacing, and pulley cone and counter-shaft replacement.

I will post more detailed shots as I go. This model of lathe seems to be highly regarded by Holbrook enthusiasts, and I am looking forward to ownership. It will help me complete a number of items contingent to restoring the big CovMac.

Holbrook, a firm based in Stratford, east London, later moved out to Harlow, Essex, and they were eventually subsumed, I believe, into the Alfred Herbert Group.

Of about Myford proportions, overall, 4 inch swing, and about 20 inches on the bed, I think she weighs about 500lb. It came with a 4 jaw and a 3 jaw chuck, taper turning unit, and a bit of cutting equipment, a few dead centres, drill chuck, etc.

Am bringing her home on Tuesday this coming week.

I would also like to track down visuals, or examples, of centre and travelling steadies, which I believe came originally supplied with this Holbrook model.

Most striking visual feature of this lathe is a milled front face to the whole bed. I have never seen that before. It is quite striking. It does not show up too well in this photograph. It has 27 screw-cutting options off its nine cog gearbox. How we attain three off each gear is not quite clear to me, yet.

Edited By CHRISTOPHER MILLS 1 on 04/04/2015 14:01:52

vic newey.

vic newey.