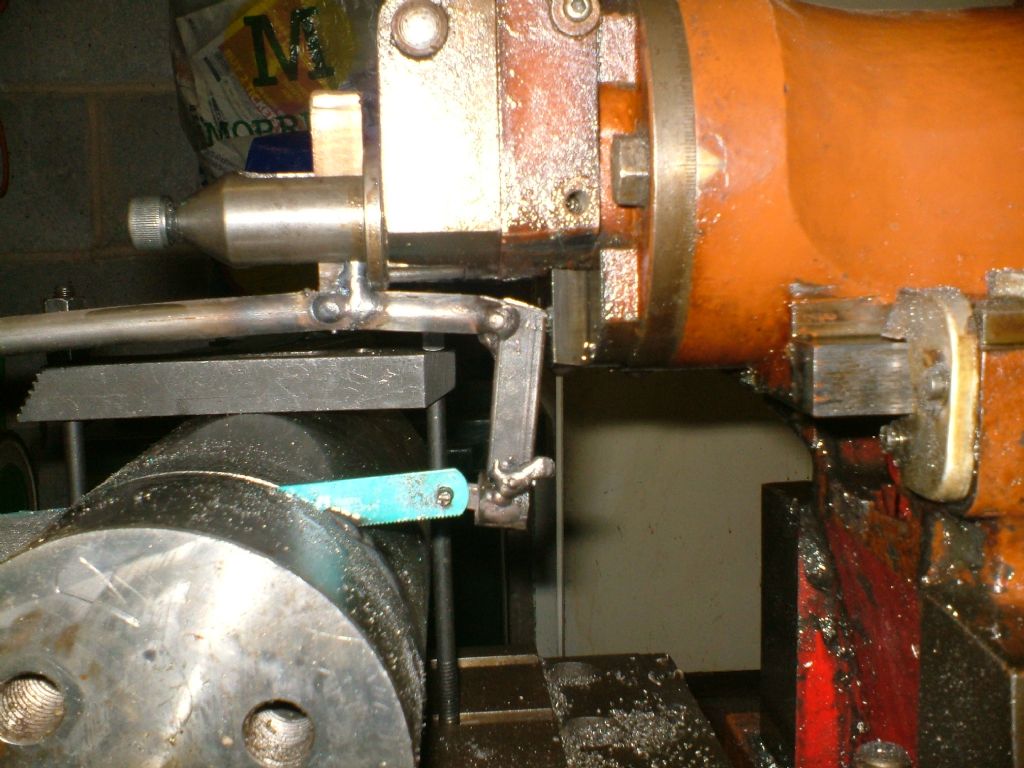

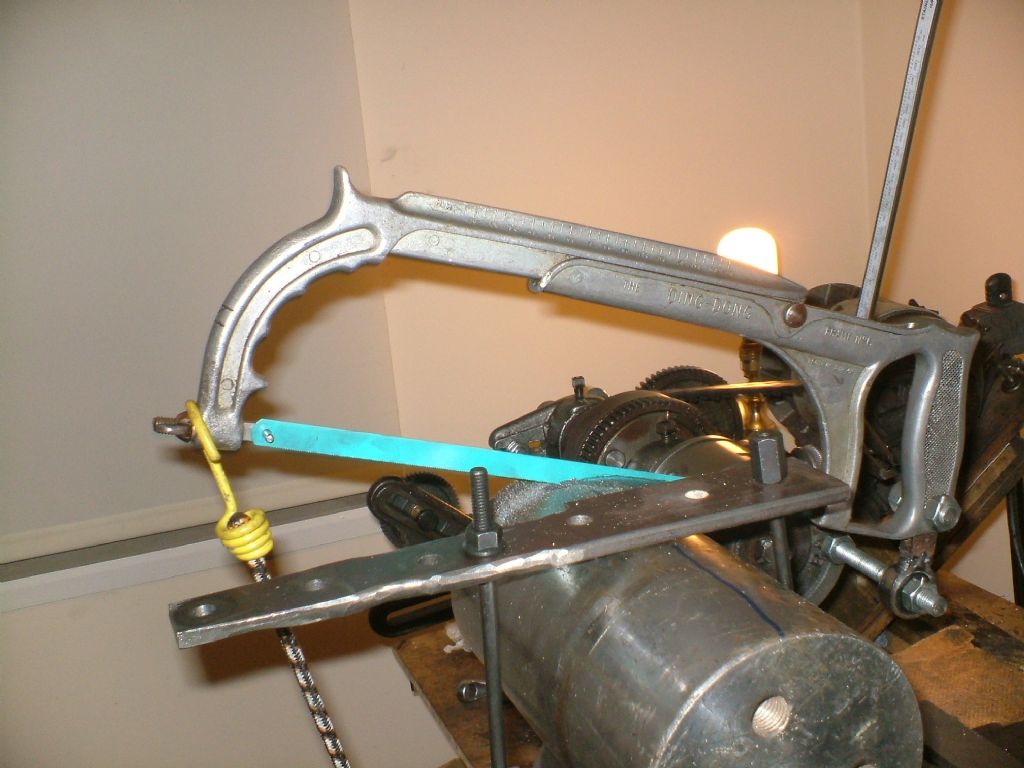

Well I had to get this billet chopped up and I wasn't going to work my shaper for 9 days again just for a slice of steel, so I returned to my old original lathe system

In the absence of a dedicated machine this is by far the least wear and tear on my equipment

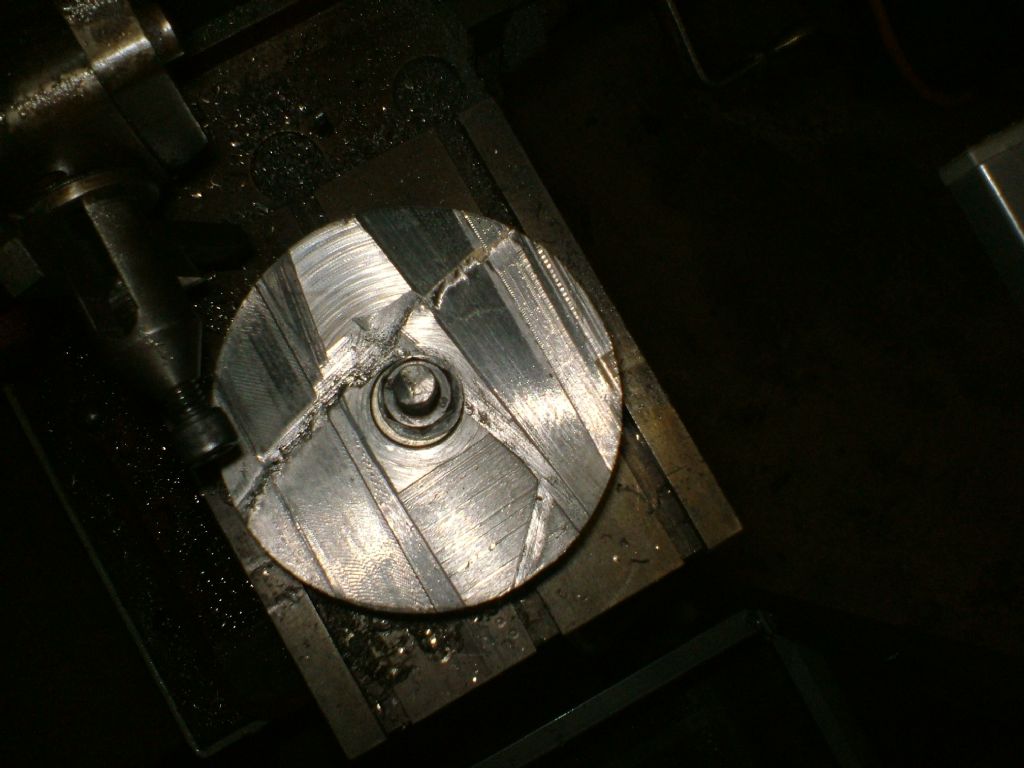

The cut got nice and deep before any adjusting was needed and a slice dropped off after the third cut

Accuracy/straightness was medium

Then came the facing off on the lathe, to save me using the shaper

5% cobalt- failed

Cleveland mo-max M42- failed

WKE 45 cobalt (tuff stuff and hard to grind)- failed

They all flattened like cheap chinese HSS

It's kinda strange because it can be drilled quite easily with cheapo hss drills

Anyway, King Carbide came to my rescue, yet again, and is doing the necessary intermittent facing off on this job. Just got to watch the chips, oh boy are they hot

Edited By Ady1 on 15/07/2015 14:05:49

Neil Wyatt.

Neil Wyatt.