Anyone got any ideas on on/off switch!?

Harry,

The M Types were originally equipped with a rotating switch known as a "Dewhurst". They are a safety hazard and many M Type users have binned them and just rely on the wall switch. If you are selling on I suggest you do the same for testing purposes, but point out to purchasers that they should ensure their own electrical safety arrangements through a professional electrician.

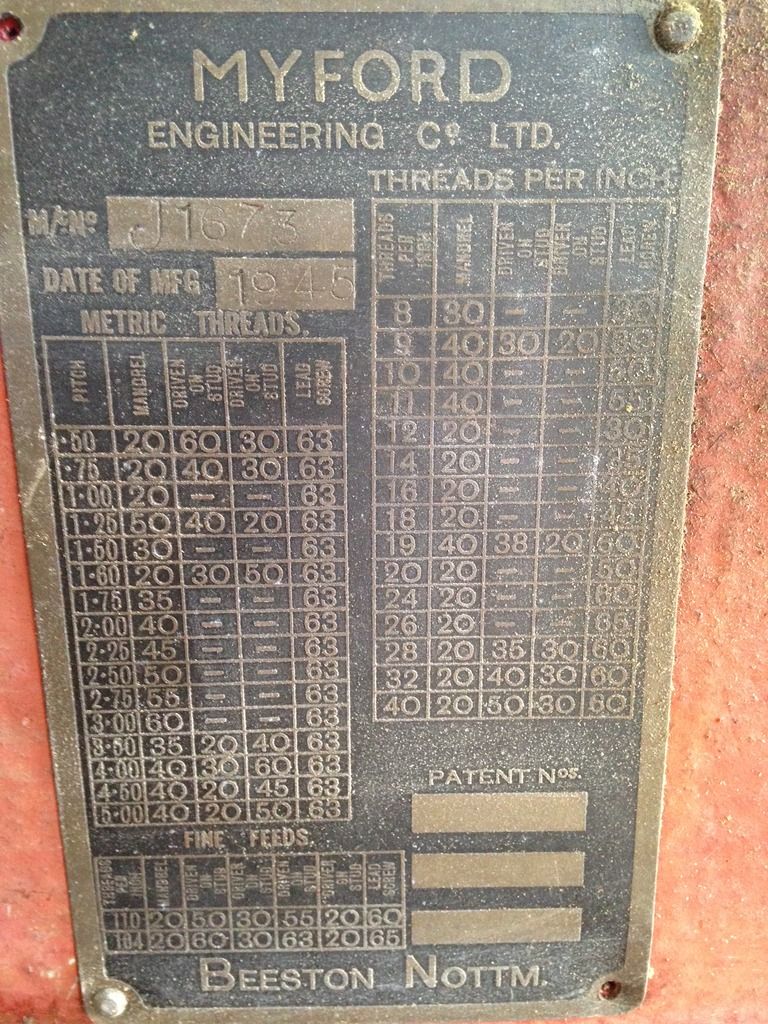

From the pics I can confirm it's a standard size Myford M Type, complete with the original Norman patent tool holder, countershaft, tailstock and belt guard. 1946 was just about the end of the production run. I don't think the stand is contemporary, it looks to be from an earlier time when these machines were foot driven, a bit like an old fashioned sewing machine; not that it matters much. The red paint is a later addition too.

Apart from change gears and chucks, the other significant missing bit is the cast iron cover for the gear train. As, when and if you sell it, advise anyone disassembling the machine for easy transport to be very careful with the cast iron motor plate unit; it's dead easy to snap it.

Eug

Edited By Eugene Molloy on 18/03/2015 18:46:33

Edited By Eugene Molloy on 18/03/2015 18:53:19

Edited By Eugene Molloy on 18/03/2015 18:57:29

Bazyle.

Bazyle.