Thank you very much – some valuable pointers (!) there.

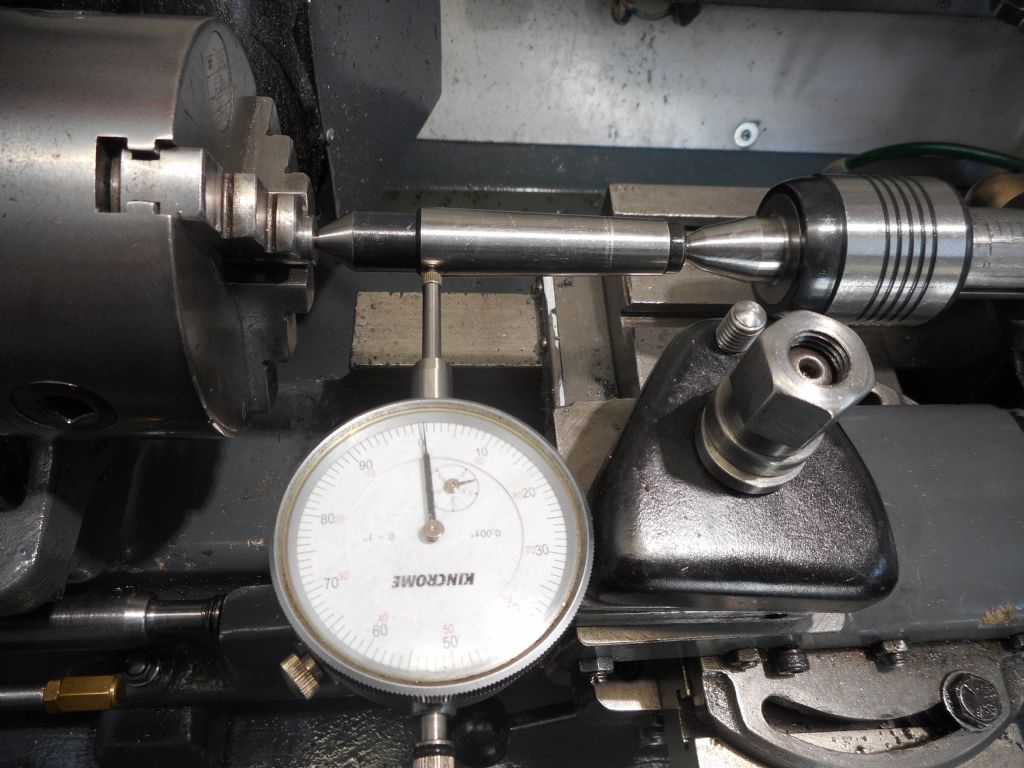

I've seen the various debates on the accuracy of tapers being affect by slight tool height errors, but had not appreciated how much this would affect the DTI as well.

Thinking about it, I recall somewhere advice that the probe also needs a disc-shaped face to minimise height error – though still needs its axis to be set as closely as possible.

Mine has the standard hemisphere, so presumably I saw the probe climbing over the curved surface by being off-axis, giving a wild error reading much greater than that of the top-slide angle error.

This shows I will need make a or buy a probe foot, and modify how the tool-post holds the indicator. As it is, it is evidently not lowering the axis of the probe sufficiently to be both horizontal and on centre-height.

I asked what I had missed, and it was clearly those two points!

'

Diogenes –

The body is a guide for the rod, yes, but more than that.

It is held like a collet, with a draw-bar screwed into a short threaded portion of its inwards end, but the draw-bar's end face is the work-stop itself.

Both ends of the draw-bar are threaded for an appreciable length, so it can be screwed through the body for a distance appropriate to the work and the chuck. The protruding tail-end is then secured by locked nuts against a flanged support bush acting on the spindle end face.

The outer end of the body is bored out to a loose 1/2-inch to one-inch depth, and anyway its end face retreats into the spindle by about 0.1 inch. (Spindle bore, 0.60" )

The arrangement is to let work-pieces enter the spindle by about an inch. The bought depth-stop's minimum setting protrudes from the spindle by nearly an inch, the work-holding problem I am trying to solve.

The immediate project involves parts about three inches long, held in an ER collet for best concentricity. If I make a new body with a much longer tail-end spigot I could even extend the working range, sensibly by up to perhaps another inch.

.

Nealeb –

The adaptor I used is so long it is hard to see it being very useful as that, at least not on a bench-drill! I think it is actually an extender rather than taper-size adaptor; but the parallel part is about as long as its taper part.

Also, the constricted space meant I could not hold its outer end on a tailstock centre, at least not without that at full stretch so compromising the accuracy anyway.

As to the tailstock centre-height's accuracy… well, yes, I should examine that. This is an old machine, after all.

So I'll try your approach, but will also see if it's feasible to re-fit the top-slide turned end-for end so it does not fight with the tailstock. Though I'd need ensure it also misses the headstock and keeps my hands well clear of the chuck or collet.

Edited By Nigel Graham 2 on 29/05/2023 11:43:42

old mart.