Fully agree Neil.

For a while years ago I worked at Raglan lathes which for their day were a decent lathe and well made. A lot of skill went into them.

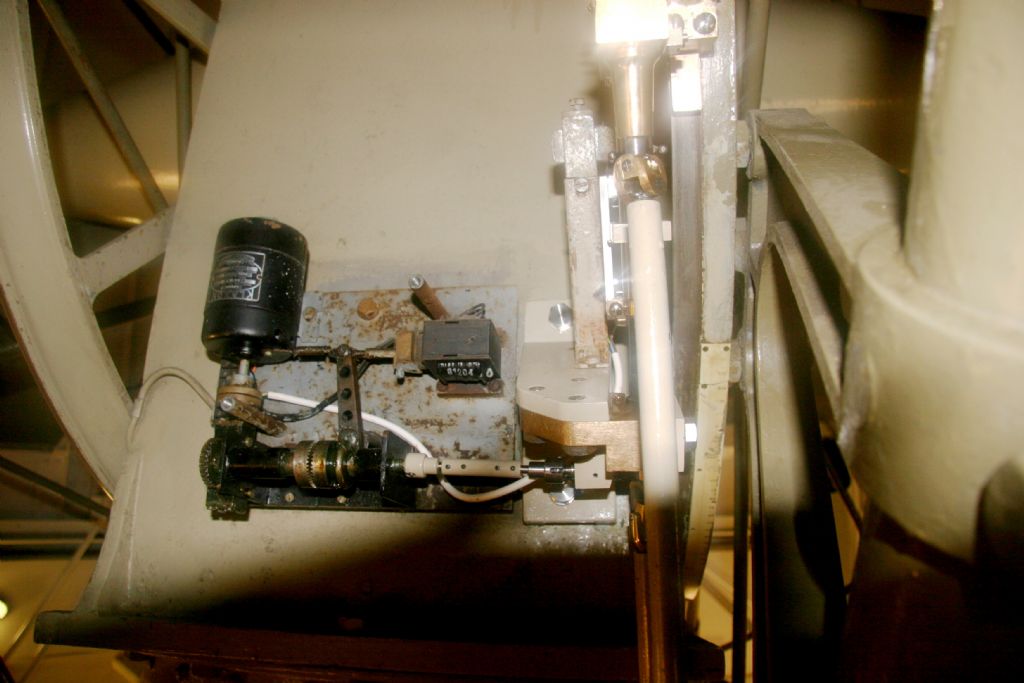

The leadscrews were made on a special threading machine that was made by them. It was basically an old lathe with two leadscrews, one set for 8 tpi and the other geared to give 1tpi.

In operation it moved forward and cut the first cut, at the end of it's stroke a cam removed the cut, engaged the second drive and returned the carriage to the start and a new cut was applied and this went on until the thread was cut. It also carried a bearing type travelling steady to keep it straight when cutting.

This operation was fully automatic and no one ran the machine. Once it stopped anyone passing would take the new screw off and replace it with a blank and press go.

Because of internal stresses these screws came off bent like a banana. The shop fitter would collect them up, bung them on an arbour press and straighten them between two vee blocks by eye but in all fairness he's been doing this for so long he was very good at it.

Point I'm making is, that in no point of the process was a screw checked for errors. From also going round Myford's they had roughly the same quality control as Raglans. I even asked the guy responsible at the pre sale if they were checked and told no, they relied on the machinery.

So if no checking is done on these 'budget' lathes what is the point of trying to work to microns ?

Ajohnw.

)

)