Advise from the Collective needed please.

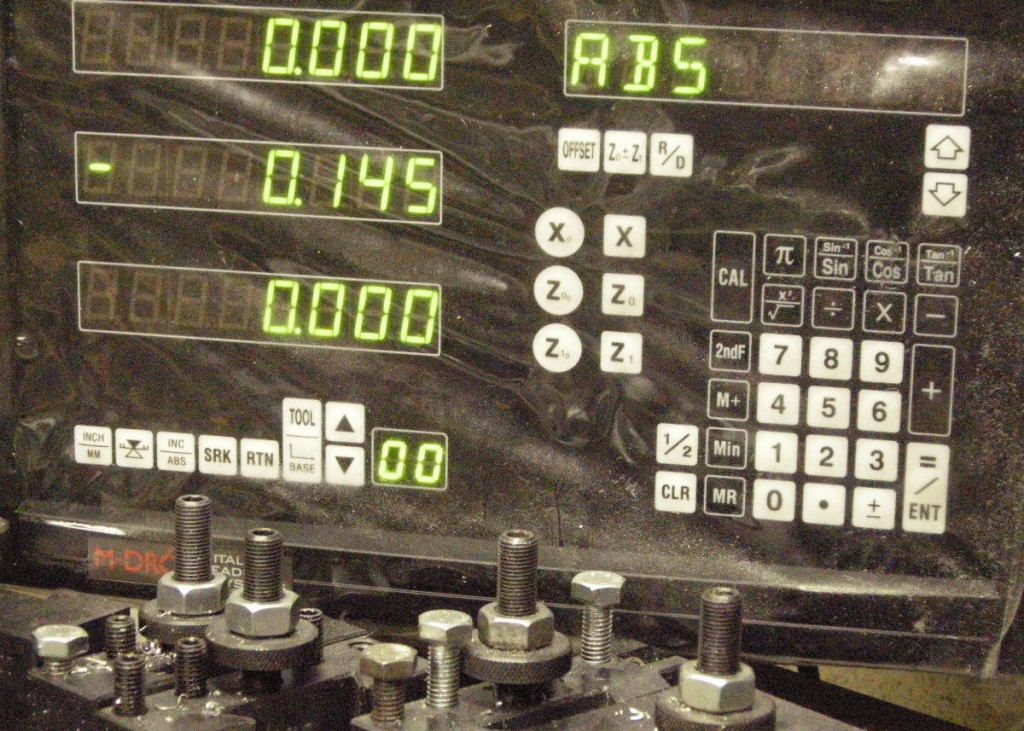

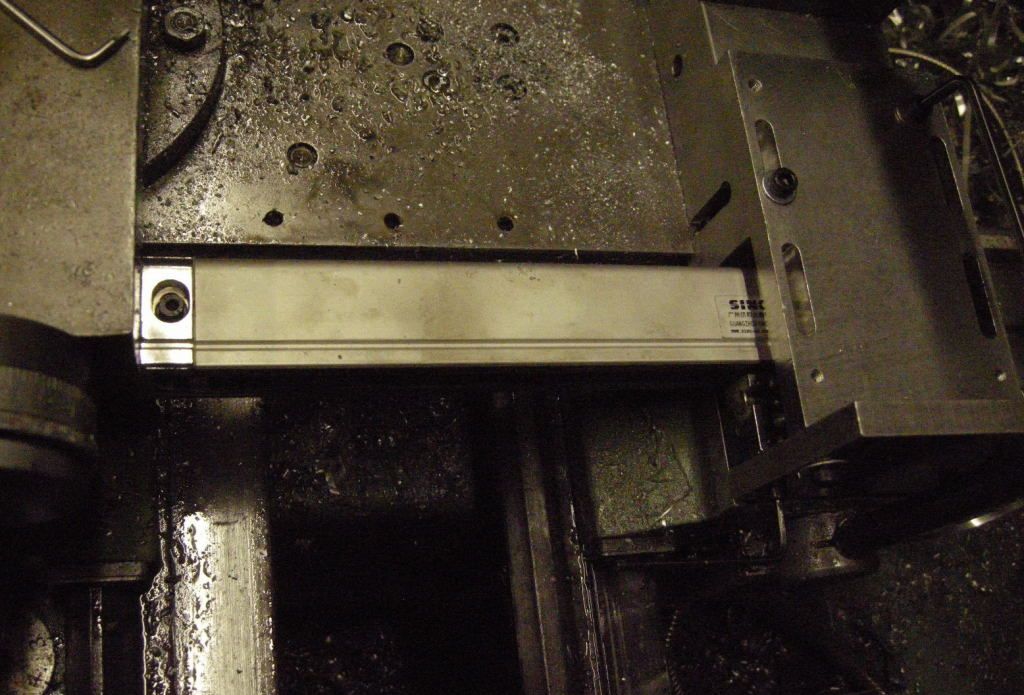

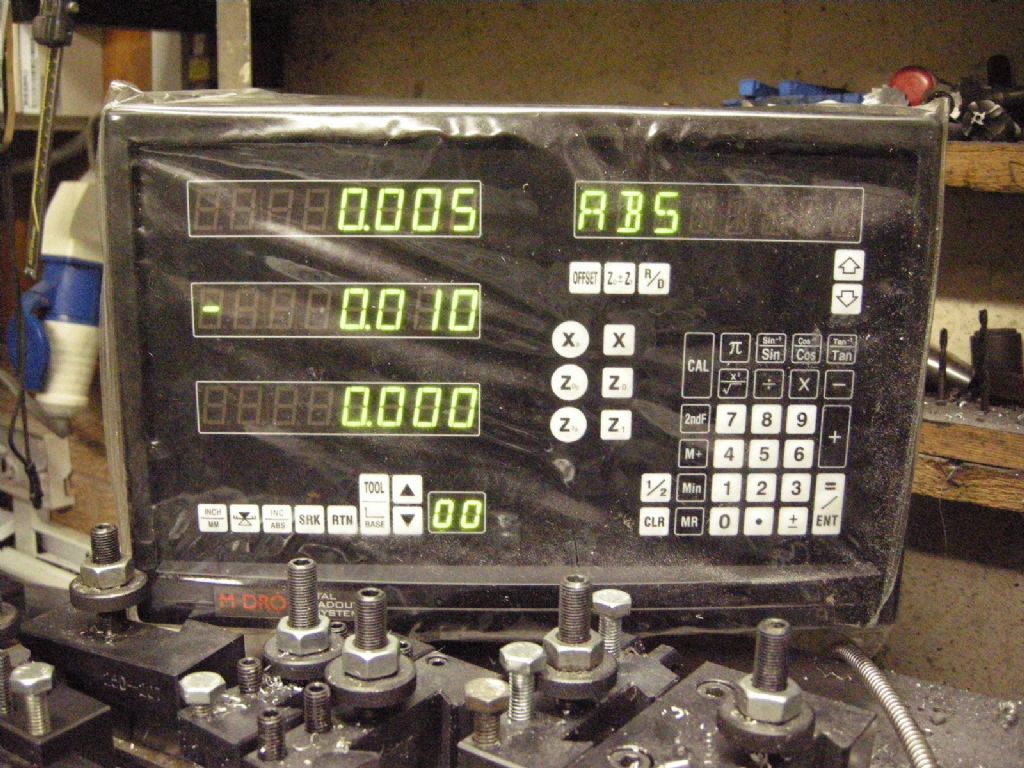

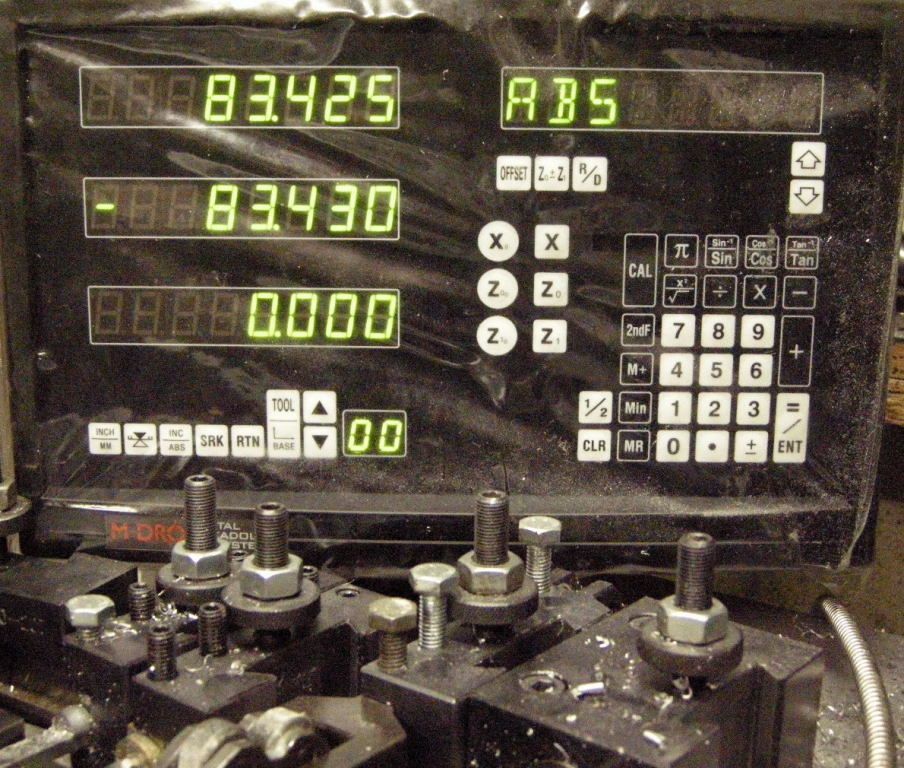

Whilst attempting to resolve the problem with the PWM for the FeedRodMotor, I need to think up a way of mounting two of Ketan's digital scales (Digital Readouts with Dedicated Remote Display).

Rather than reinvent the wheel, and more to the point save time and brain cells, I would prefer to get help from the Font of all Knowledge.

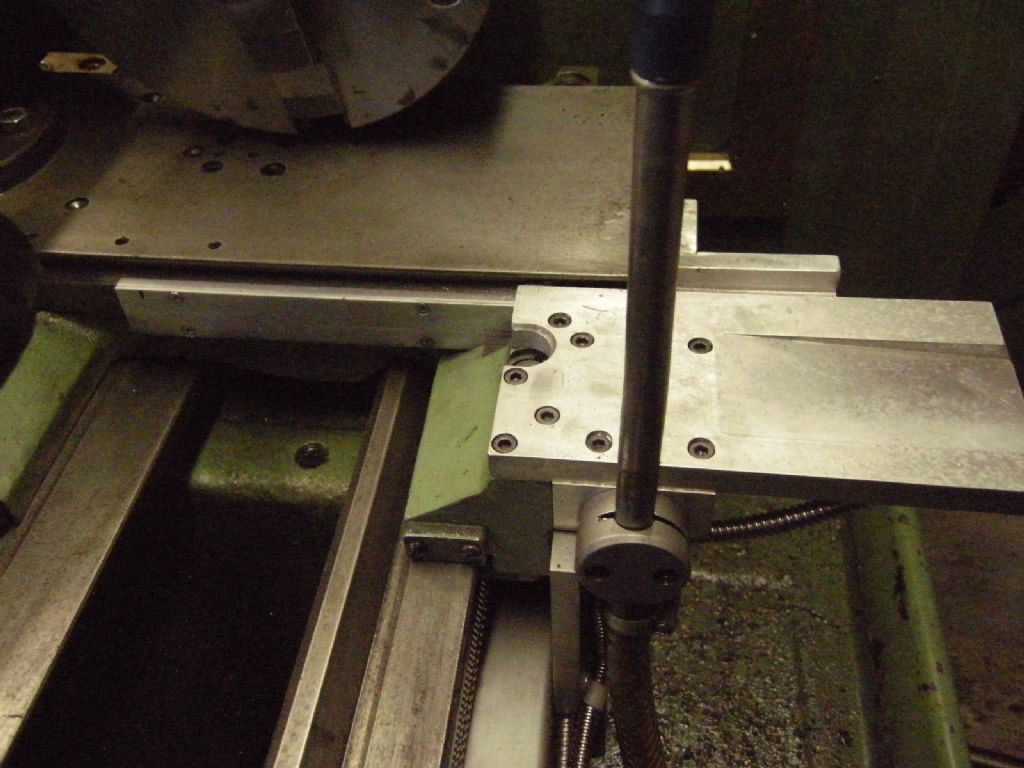

Y-axis:

This is the one giving me headaches, as however fitted, it's going to be tight, fitted either vertically or horizontally.

X-axis:

I was thinking, only thinking mind you, of mounting the scale on the front of the Bed, it being more accessible and having space now that I've removed the Spindle Direction Rod I no longer need.

Suggestions, brickbats, kicks up the Nile (not)appreciated.

Geoff – Lots of Workshop time today with luck

Edit:

Oops – 'a' in the Subject line should not be there

Edited By OuBallie on 11/10/2014 09:52:44

Paul Lousick.