Jamie: Here are some more thoughts:

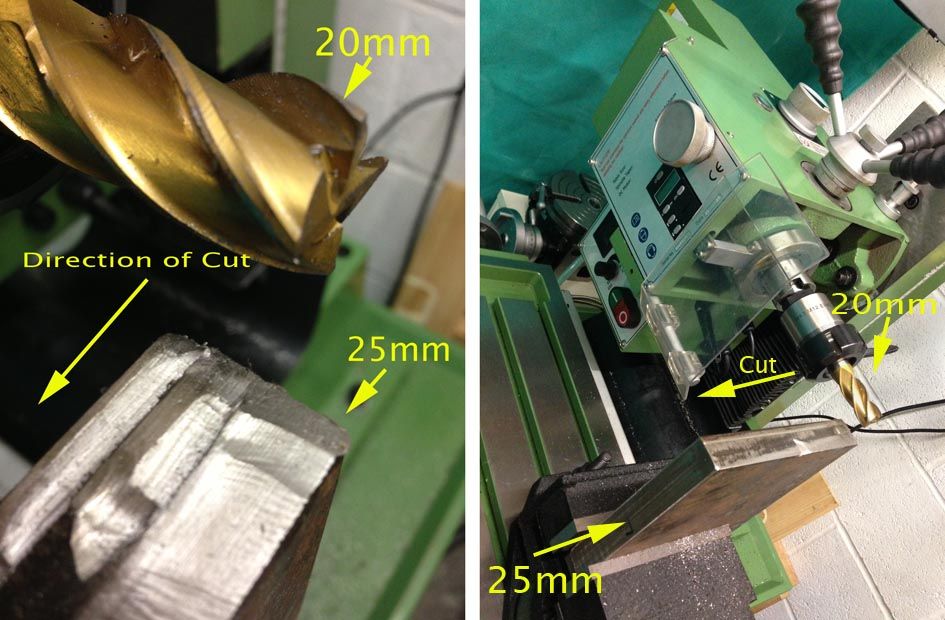

3. It is difficult to say what power is available at the spindle without knowing more about the drive arrangements. However, I'll make an assumption that the mill uses a DC motor with PWM speed control? I note that the spec states two geared ranges; were you using the low range. We can do a simple calculation to get a feel for the power needed. A rule of thumb states that 1hp will remove 1 cubic inch per minute in low carbon steel. So if we assume that your depth of cut is 0.08" (2mm), width of cut is 1/4" (6.35mm) and feedrate is 6" per minute (~150mm/min) we get 0.12 cubic inches per minute, ie, about 90W. I would have thought the mill should have no problem achieving that. There is a caveat though; the setup may well not be rigid enough even though the power is adequate. The feedrate may seem a bit high, but it does take into account 'chip thinning' (Google it) as the depth of cut is shallow compared to the cutter diameter.

4. Personally I'd bin the cutters and buy a brand name one, say Dormer, Guhring etc. A HSS cutter should be fine, and no coating is needed. There are two rules for buying cutters. One, never buy cheap cutters; two, see rule one. Cheap unbranded cutters are often poorly ground with incorrect clearances, or even no clearance, and can lead to intense frustration.

5. The ER collet chuck definitely doesn't look right, you ought to be able to see the collet flush with the closing nut, between the nut and cutter. Follow the link provided by JasonB for details.

6. I meant that the distance from the point where the spindle exits the milling machine head to the end of the cutter is quite long, 5" or so? Cutting forces will cause the cutter to deflect and overhangs make it disproportionally worse. The rigidity follows a cubic law. In other words if you double the overhang the setup isn't half as rigid, but only 1/8 as rigid, so way more deflection.

I don't see why the mill shouldn't accomplish what you want, but I think the setup and cutter are the limiting factors at the moment.

Regards,

Andrew

Bob Brown 1.