Hi Andy,

You probably feel like my technician by now, but i do appreciate the advice. The fact that i get to talk to someone about this stuff is fantastic, my partner shows zero interest (i think she's a woodworker at heart).

I've sorted out some oil, very hard to find in small quantities, but there is a single supplier on ebay that was able to help. He said the iso22 was probably too thin despite it being recommended for southbend lathes (perhaps a different system) and suggested i use the iso68 machine oil for the spindle, as well as the open gears for screw cutting. This is not really an issue but i do prefer things to specifically state their use on the label. I've included the description below if you're interested.

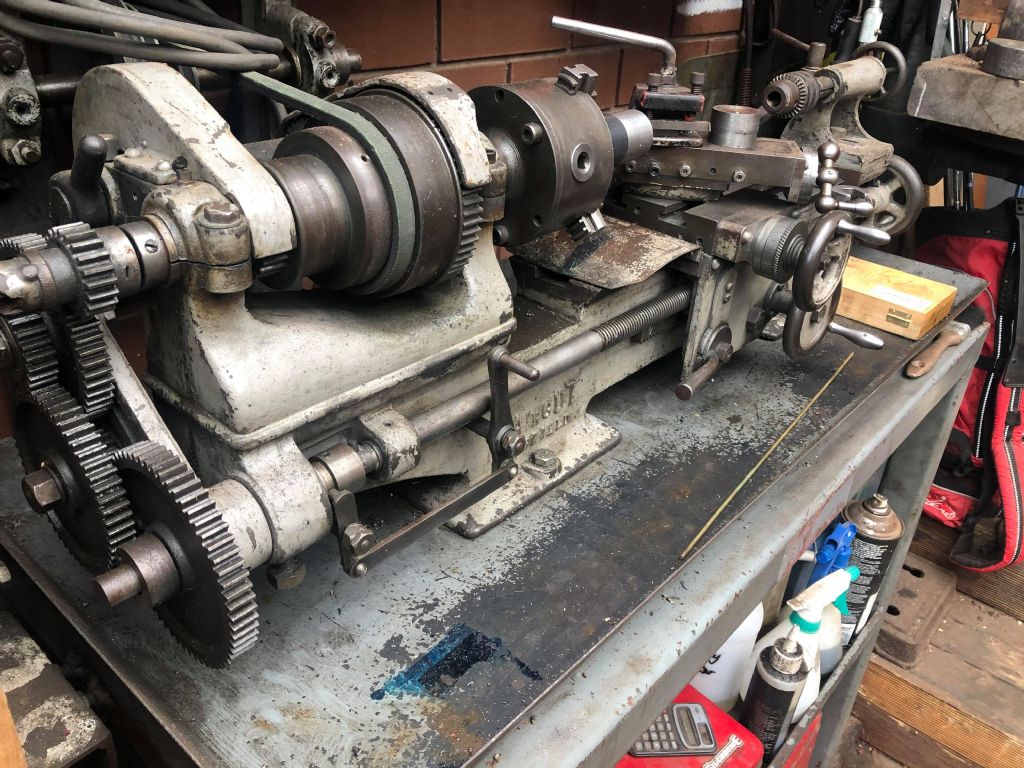

As for the leadscrew, you are correct. I suspected that the wheel could be moved inwards to take up the end-play. How much so, i was not sure, but now i am. I know it seems excessive but when i hold it in place, i cannot move the carriage at all. The slide wheels wind in and out, which appears to be an adjustment issue in the brass nut underneath (from what ive read).

This is the lock but i'm not sure if it's factory. Also pay close attention to the tooling. It is 1/4", yet still a few mm too tall. I'm at a complete loss as to what tooling was used in this tool post if 1/4 is too small. This is why i was so confused in the first place.

The bearing casting is frightening as i can honestly see it happening. It's cast iron and its old, who's to know how much it will take. I might put the shims back in as i took them out before addressing the backlash issues. Surely they could not have been like this from factory, it would be fascinating to know for sure.

The oilers are tiny and one is missing its hinged cap. The other one is the perfect size for a brake nipple cover. Although having seen your foil solution, i'm tempted! I'll try out the different grades for oil and see what needs to be done, excluding modification, of course. Maybe i can add oilers with the same size thread (if they exist). I'm more worried about whether or not i should remove the spindle to clean all the motor oil out. The motor spindle, however, has an interesting setup. Obviously not factory, it uses a bearing cap i'm not familiar with. I'm not sure if i'm supposed to squeeze oil in there with a sauce bottle or not.

Once again, thanks for looking!

Brian Morehen.