My experience is that this can be also be caused if the developer is too concentrated and therefore too aggressive, but this happens very quickly. I use plain caustic soda, and had this problem until I halved the concentration from what the net suggested.

The other times I have has this are when the resist has been under-exposed.

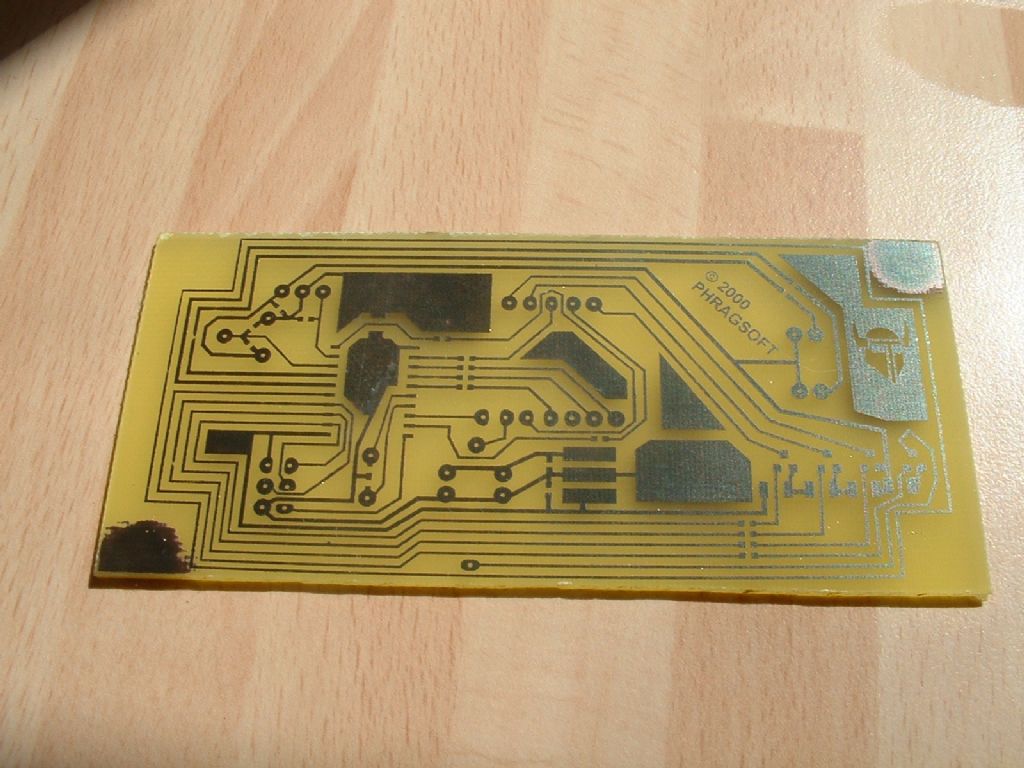

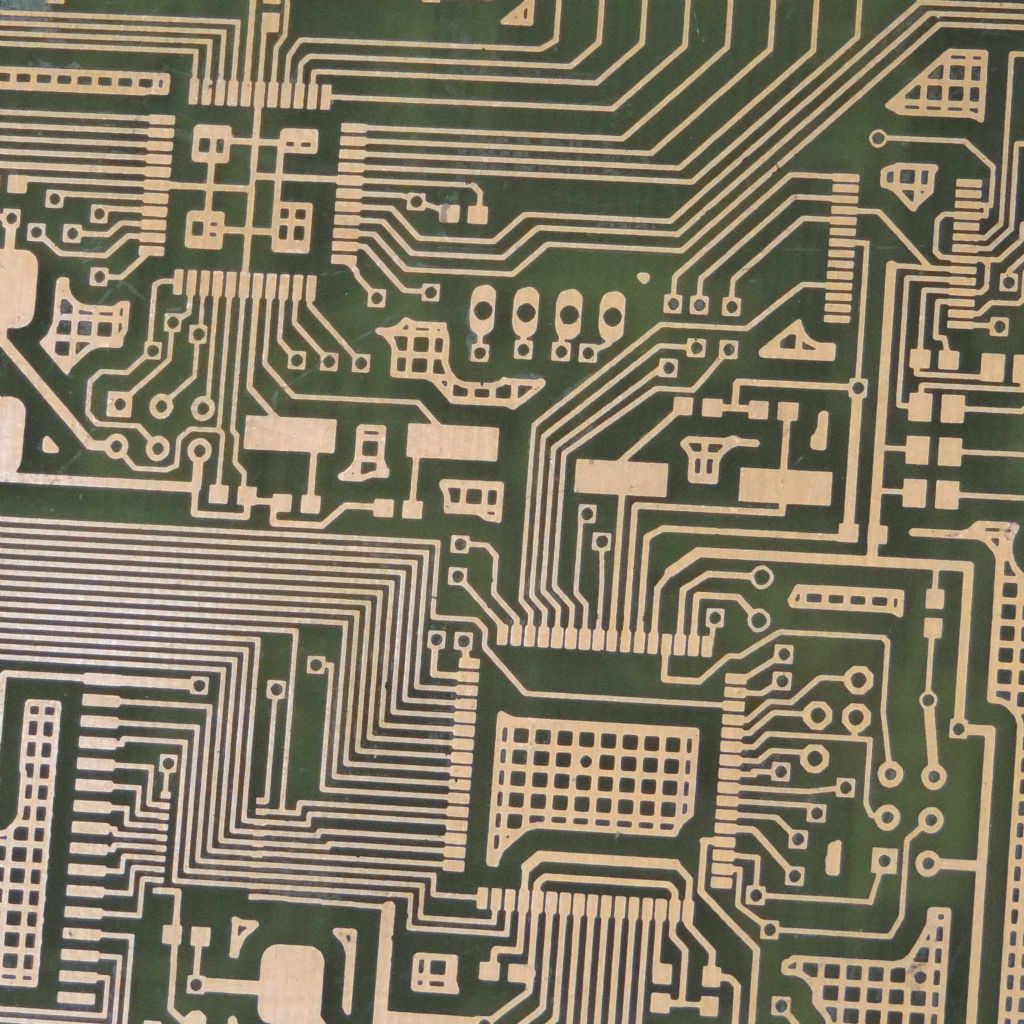

I calibrated my set-up by putting a resist coated strip about 5cm long of PCB material on the UV-box, with just 1cm exposed and a long bit of card covering the rest. Tape the PCB (or brass) so it can't move. Expose, and after 30 seconds pull the card along by 1cm. After 2 1/2 minutes the whole pieces is being exposed, so leave exposed for another 2 1/2 minutes. You now have five adjacent sections exposed for 2 1/2 to 5 minutes in half-minute steps. Drop it into the developer (agitating it well, and it can help to use a VERY soft small brush to move the dark strands off the piece) and you should rapidly be able to see the strips clear of resist in turn. Make a note of how long the work is in the developer at the point where you get a clear demarcation between two strips. You know know a good, reliable balance of exposure time and time in the developer.

Also, if you put the developed work in the etch all exposed copper or brass should turn pink almost instantly. if they don't, RINSE WELL and back to the developer. My last board was underexposed along one edge (probably greasy fingers – I am sure finger marks stop UV) so I ended up leaving that part of the board in the developer for much longer.

My exposure time is about 4 minutes and developer 2-3 minutes, information which will be of little use to your, as your set up will inevitably be different.

I used to use inkjet film, but now I use 3M laser film in a HP deskjet (because a £5 laser cartridge that does 3,000-6,000 pages is cheaper than three injet carts at four times the price…)

Neil

David Cambridge.