On the subject of the EMG-12, here is an email response sent to me by Bill in Australia. It does not specifically cover the questions raised, but still, I am posting it here. I am finding it difficult to persuade others to post. They have their own reasons, but I have obtained permission for this message to be posted. (Thank you Bill)

Before reading the comments, please note that this is only being posted to address certain attributes of the EMG-12 from a user of the product. ARC has the greatest of respect for other T&C grinders – home built or commercial. We have no axe to grind with anyone or any other T&C Grinders, all of which have their own attributes and/or additional features. For the record, I get on well with Ivan Law (the respected gentleman responsible for the Quorn) and Derek (DAG) Brown, both of whom I meet at the Harrogate Show recently, where Derek was showing/demonstrating his Quorn T&C Grinder. Glad to see that both are in good health

"Hi Ketan,

Having said my bit in the early stage of the discussion, I would like you to know how much I appreciate the opportunity to have been able to buy an EMG-12 from you and have you ship it out to me in Australia.

I bought it with the anticipation of it meeting 3 criteria which are important to me.

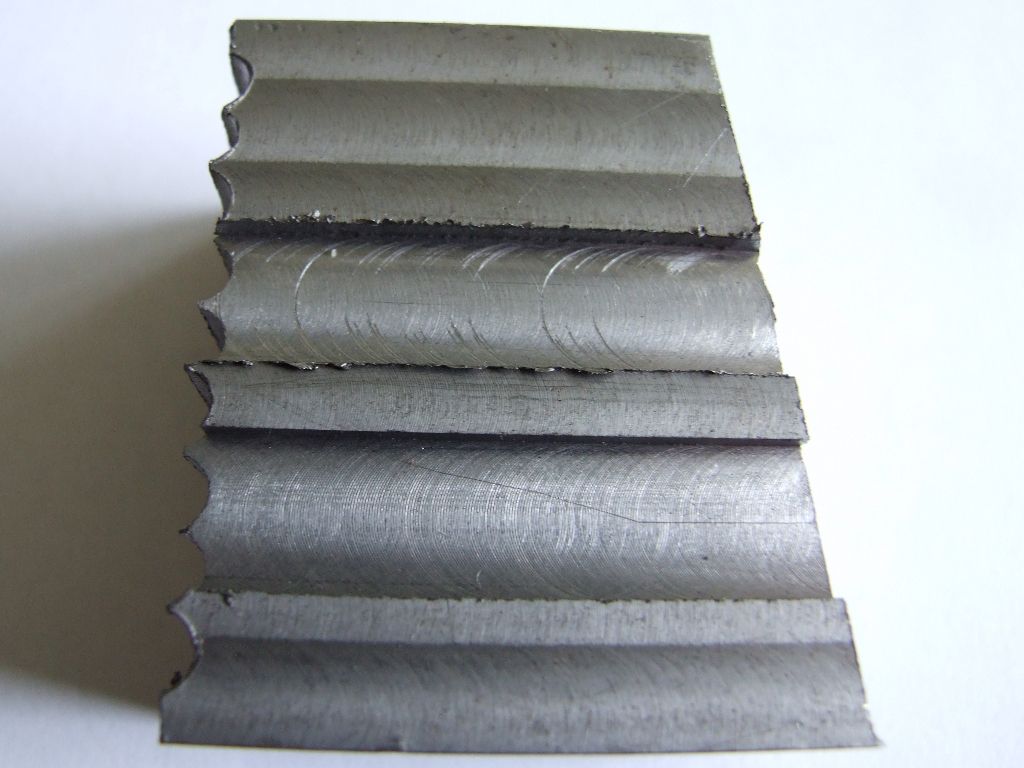

1. I wanted it to recover and produce sharp end mills repeatedly.

2. I wanted it to do that quickly?

3. I wanted it to be easy to use so even I could get the desired results.

I am happy to report that it has achieved 100% in each criterion.

All my end mills, 1/2" and less, both metric and imperial, are razor sharp. I have tested each one and they cut as well as when they were new. I will now not use or need to use larger cutters other than to enlarge 13mm holes in the lathe to accommodate a boring bar.

I must admit the add in MEW did not attract my attention until I read the review. It was the concept of being able to quickly sharpen a cutter after use in readiness for its next job that really appealed to me. I have been using a Quorn T&C grinder for years. I think I can say that I became frustrated every time I used it. I always had blunt cutters and it would take me a whole session in the workshop just to sharpen the ones I needed at the time. I will now sharpen my few large end mills on the Quorn as they wont t get a lot of use and my smaller end mills will always be razor sharp. At 77 I don't want to waste any of the time I have left getting frustrated.

Thank you again. I hope those last 3 EMG-12s have been sold and that you are getting more in because I am sure model engineers will eventually see the real benefits of the machine and then they will "justify" the purchase of one.

Bill Adamson"

Ketan at ARC

John Stevenson 1.