Thank you one and all for your advice. Sorry I have not come back in before now. Redecorating and grandchild.

The hex bar I used was found in a yard years ago so no idea what it is. It does come off in small chips and screams as it goes, and to me, dos’nt seem as dark ? coppery as bronze or gunmetal. Mind you, I’ve not much experience of them. I had a couple of hours yesterday (emulsion drying), went out, rather chilly, and cut an inch or so off one of the jamming drills. Resharpened + neg. rake, not as bad this time but still jamming. I had thought of relieving the drill sides a few mm below the facets just to try it.

I then, ala asymmetric sharpening, used a forcing bar, idea from Mr. Sparey’s book, well a piece of wood between the toolpost and the drill shank to push over the drill a touch to clear the existing hole out. That worked. I then picked a 9/16 drill, touched the edges and tried again. After a lot of “pecking” running the coolant over the outside of the job, WD in the bore and drill pulling out a couple of times I got thro. I can now use a boring bar.

I remember I was drilling out a brass electrical cable gland on a pillar drill, might even have been for the QE2, bit above inch, when the drill jammed, whirled the machine vice complete with gland round until it hit the drill pillar. The vice of course was not fixed to the table.

Promptly snapped the drill . Luckily for me the machine was at the rear wall of the shop so nobody really noticed the bangs amid the general noise. Bits into scrap bin and try again. I’ve been a bit wary of brass since.

Mike Williams. No. The piece protrudes beyond the chuck and wall is still about 6mm. I think a D-bit might be the answer. But no silver steel.

Jason Udall. Funnily I did think it seemed to work harden.

MGJ. I will try a test with no pilot with my old drills. High feed rate. Fear is the answer.

Ian Hewson. I’ll try a brand new one. My old drills could, are, 10’s of years old.

Andrew Johnston. Did not know my son did model engineering.

Regards to all.

Anonymous.

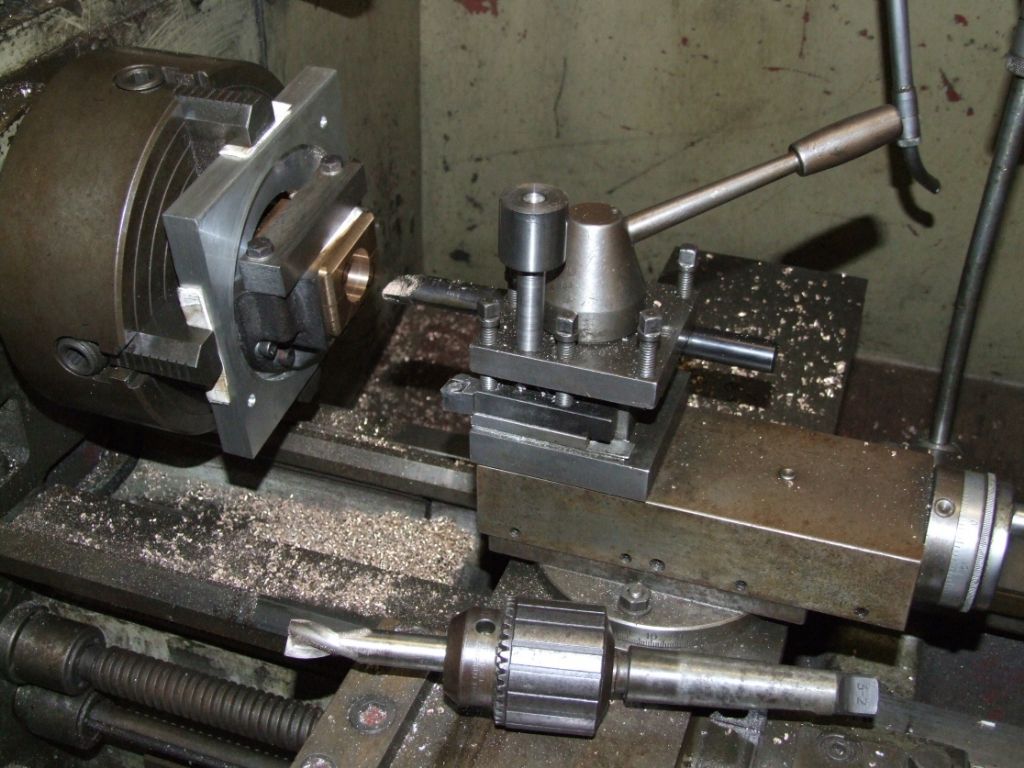

Here’s a picture of the set up, with the bore finished:

Here’s a picture of the set up, with the bore finished:

)

)