According to Ivan Law's book, a No 1 cutter is for cutting from 135 teeth to a rack, so is most definitely not suitable for cutting a 11 tooth gear.

If you do not have a copy of his book, ("Gears and Gear Cutting" No 17 in the Workshop Practice Series), you would find it a great help.

A No.8 will cut 12 – 13 teeth, so your 11 tooth gear is off the scale of standard Browne and Sharpe type gear cutters.

These are the normal numbers for Browne and Sharpe type cutters.

You can cut 11 teeth with a No 8,but the tooth form will be slightly incorrect. As already suggested, by adjusting the depth of cut slightly you may finish up with a useable gear.

Cutters are available from various suppliers (The last one that I bought, a 1.5Mod No 8 for a 13T gear, cost £22 from RDG Tools)

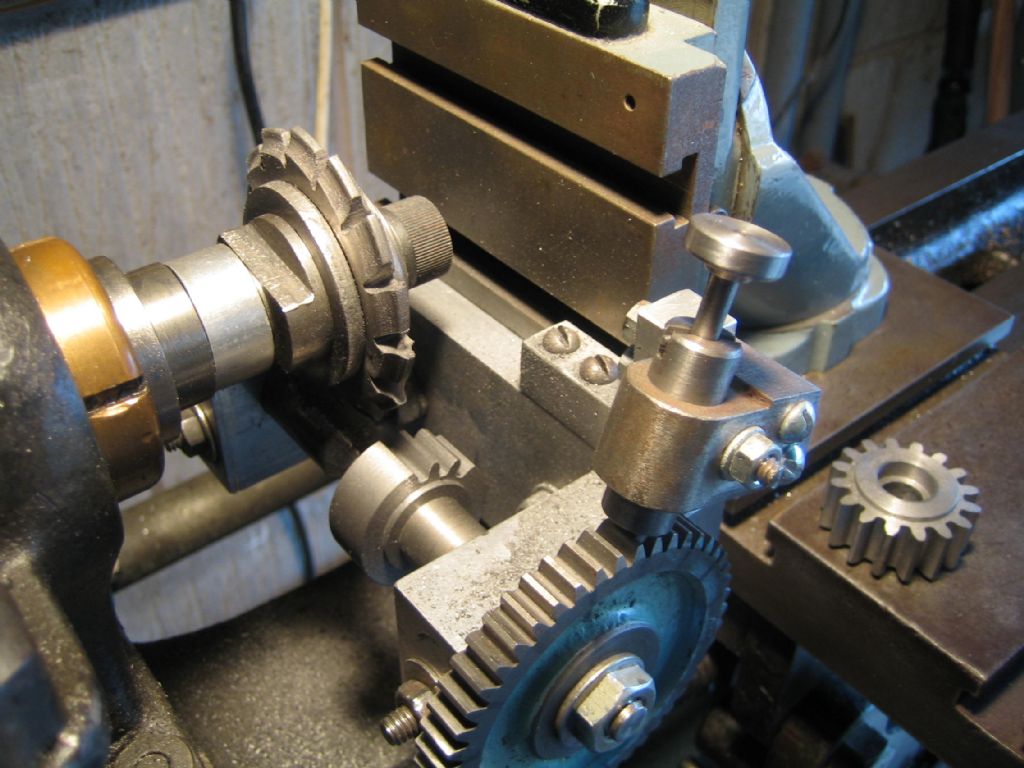

Arbors are available, or you could possibly make your own. For this you need a stub arbor (possibly plus and adaptor) to suit the spindle on your Mill. Mounting the arbor in your lathe, you turn the plain diameter down to to be snug fit in the bore of your cutter, and tap the end to take a suitable (preferably countersunk head) Allen screw with which to clamp a recessed Washer to clamp the cutter to the arbor.

Armed with this, you clamp the cutter to the arbor, and mount the assembly on the mill.

If using a vertical mill, you will need to bring the centreline of the cutter to coincide with the centreline of the arbor carrying the gear blank.You are then ready to cut the first tooth (or the space between it and its soon to be neighbour), by feeding the gear blank past the cutter. Having once set the depth of cut, and made a cut, (gentle feed!) I would advocate retracting the stationary cutter away from the blank, before indexing the blank for the next cut.

If using a horizontal mill, you will be traversing the gear blank, vertically rather than horizontally, past the cutter, so again, the centreline of the arbor carrying the gear blank needs to coincide with the centreline of the gear cutter. Or you could traverse the gear blank under (or over) the cutter in the horizontal plane.

Howard

Edited By Howard Lewis on 04/05/2018 18:37:14

Michael Gilligan.

Michael Gilligan.