Posted by Martin Whittle on 01/12/2018 21:20:21:

Posted by larry phelan 1 on 01/12/2018 16:30:48:

No machine is any more accurate than the machine which made it

So would you like to explain how we got from chipping wheels out of stone to modern precision machinery?

Martin

Martin's comment suggests an alternative approach that does not require a high-precision square. Precision tools are useful in a workshop because they save time, and are easy to use. But it's possible to go back to first principles. One that might work in this case is dividing. Main disadvantage is it requires attention to detail and perhaps a number of attempts.

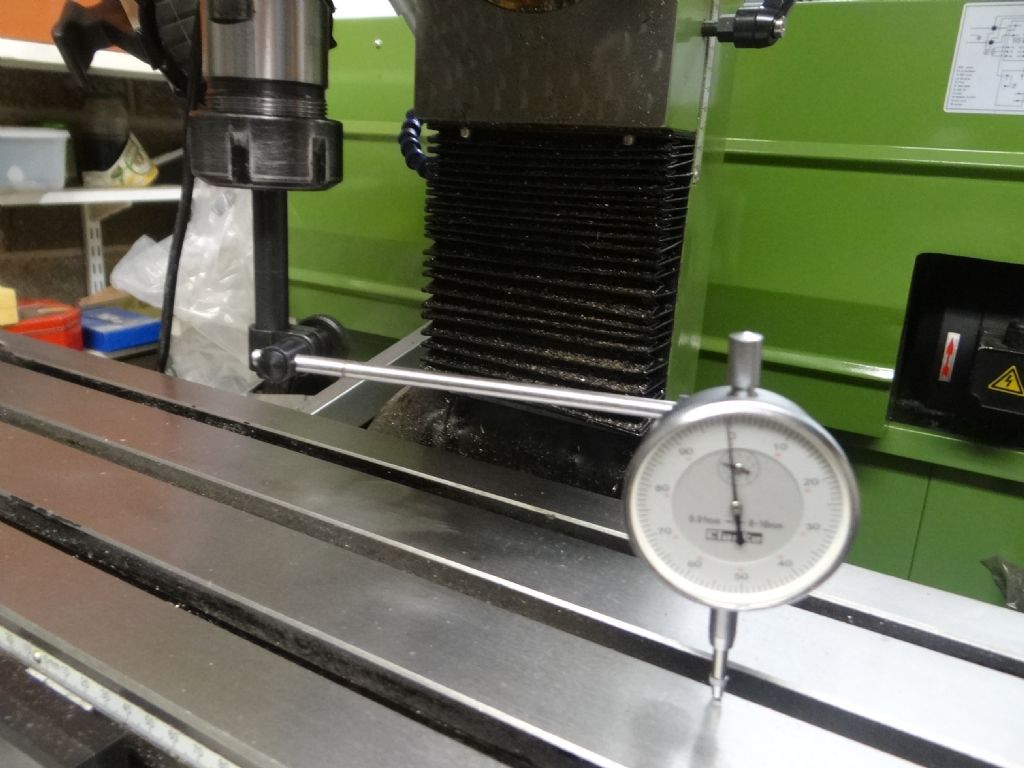

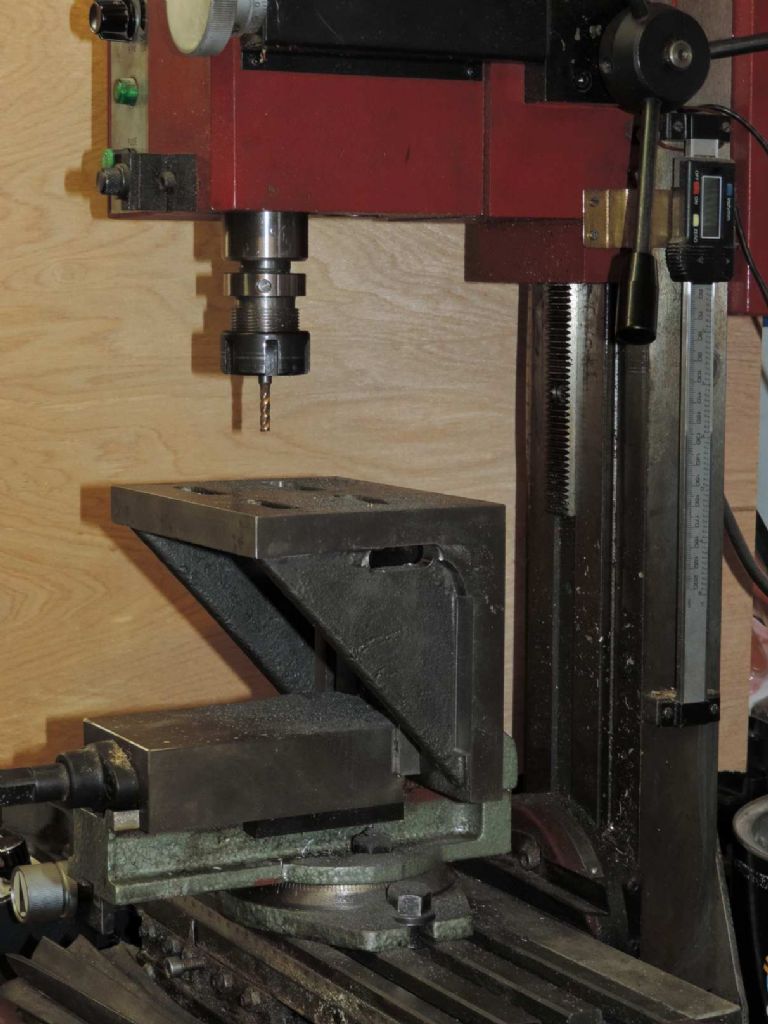

Mount a DTI in the quill on an L shaped boom as shown:

Position the DTI at North and set it to zero. Use a set-square to determine 'South' with reference to the end of the table. Flip the set square over to halve the error, even though exact alignment with south isn't that critical. Swing the DTI to that position and note the difference. Now tilt the head to halve the DTI reading.

By repeatedly halving the error it's possible to improve the alignment. It is not necessary to have a precision set-square,

On my Chinese mill there's a knack to tightening up the bolts when tramming in the normal right-left direction. Although in theory it shouldn't happen, tightening the bolts can disturb the front-back tram slightly. Adjusting the tram can be very frustrating and I avoid disturbing it if I can.

The accuracy of tram by this method depends on the length of the boom, the accuracy of the DTI as a comparator, and the flatness of the table. The skill with which the head can positioned (with shims if necessary) is likely to the limiting factor, at least it is in my workshop! Even if the table happens to be tilted, then the head will still be set at right angles to it. If the table is bent, then a regrind is necessary.

If you don't have a DTI the set up can be done with a rule, in which case a magnifying glass helps. It's not necessary for the rule to be graduated because you're halving the error, not measuring it. Dividing is surprisingly accurate and it's one of the ways in which we escaped the Stone Age.

Dave

Niels Abildgaard.