Mornin' All

Denouement?

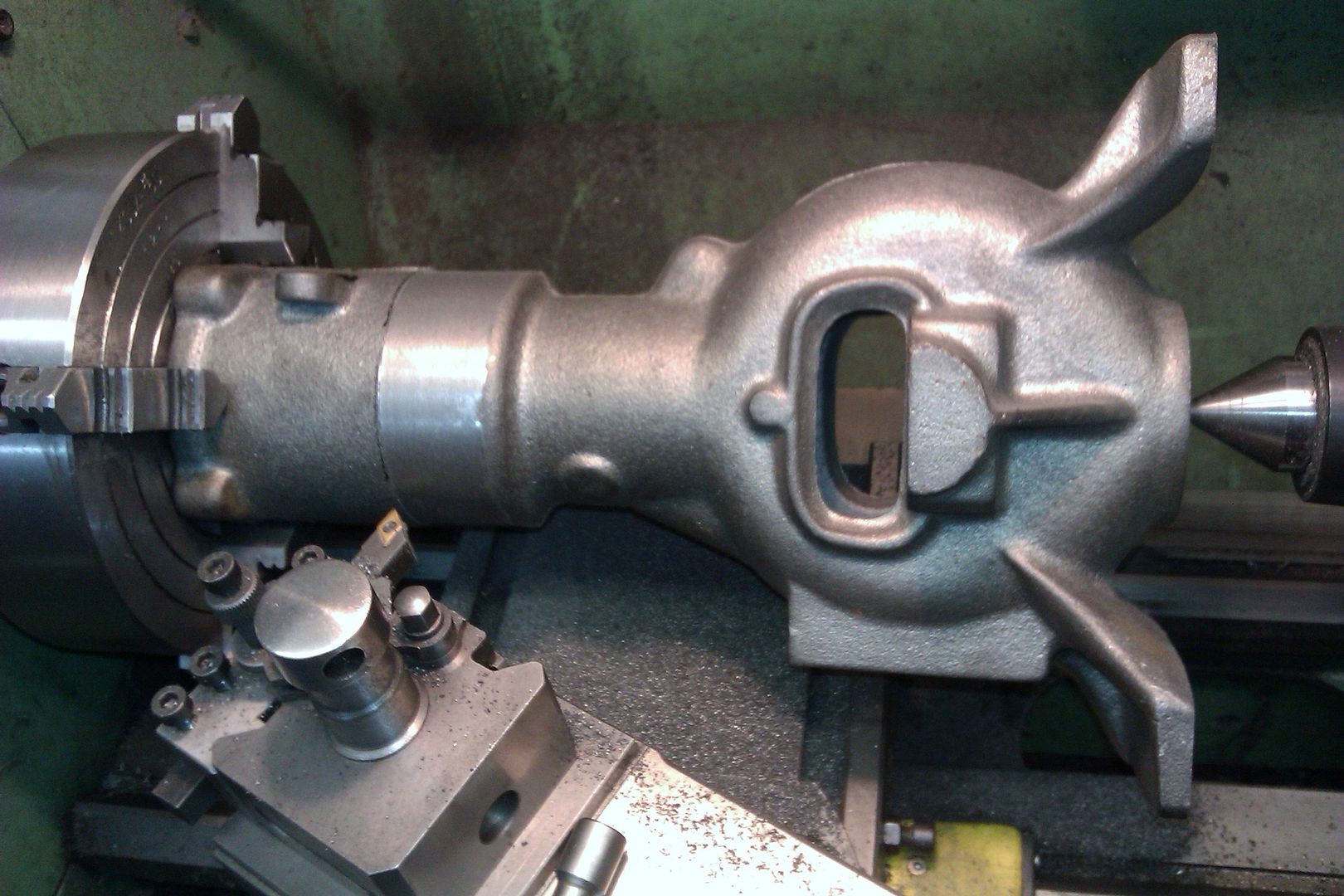

Have just run Super B lathe expirementally with Chester fixed steady and a piece of approximately 10 inch long EN24T in a 16mm collet chuck. No machined surface for the fingers for this purpose.

Everything rock solid, no movement on steady, no movement on 'work', no loosening, no heat, no perceptible run out. Kept lathe going for about four minutes with no change.

What I've done is position the fingers first so they bear squarely on the work and initially tightened them up. Located the fixed gyb (operator side of the lathe) hard against the bed, then I've slewed the gyb on the far side at an angle to the bed, wedged it with a piece of packing and tightened that up hard. Then finally tightened the fingers up hard. I also have a packing piece between the foot of the steady and centre of the bed which eliminates any axial rock.

Not elegant, but it's working.

Martyn

Neil Wyatt.

Neil Wyatt.