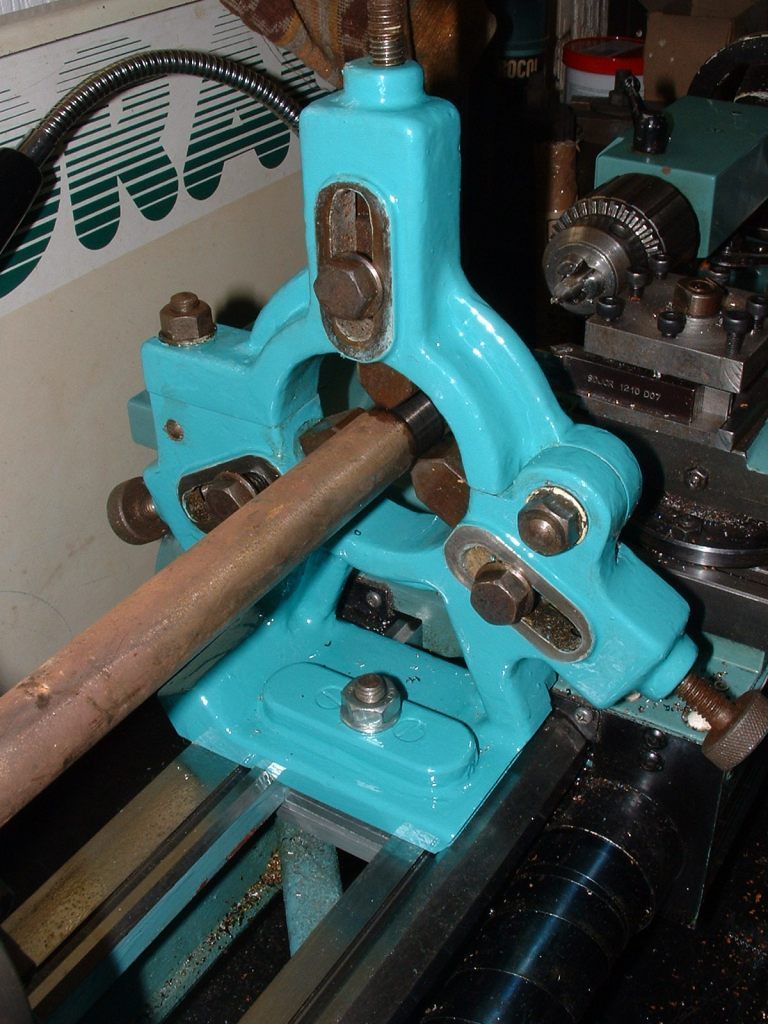

The comments about paint on mating surfaces are very pertinent.

Recently I had dealings with a Chester Conquest, and found that the surfaces that mate with the bed on both the Tailstock, and the Fixed Steady were covered in overspray. A little rubbing, with some Emery removed the overspray

And Yes, I did wipe off the dust (Hopefully all of it). The plates that clamp the tailstock, and steady to the bed look a bit flimsy, to my mind, but that can be remedied in time. Other jobs intervene, currently.

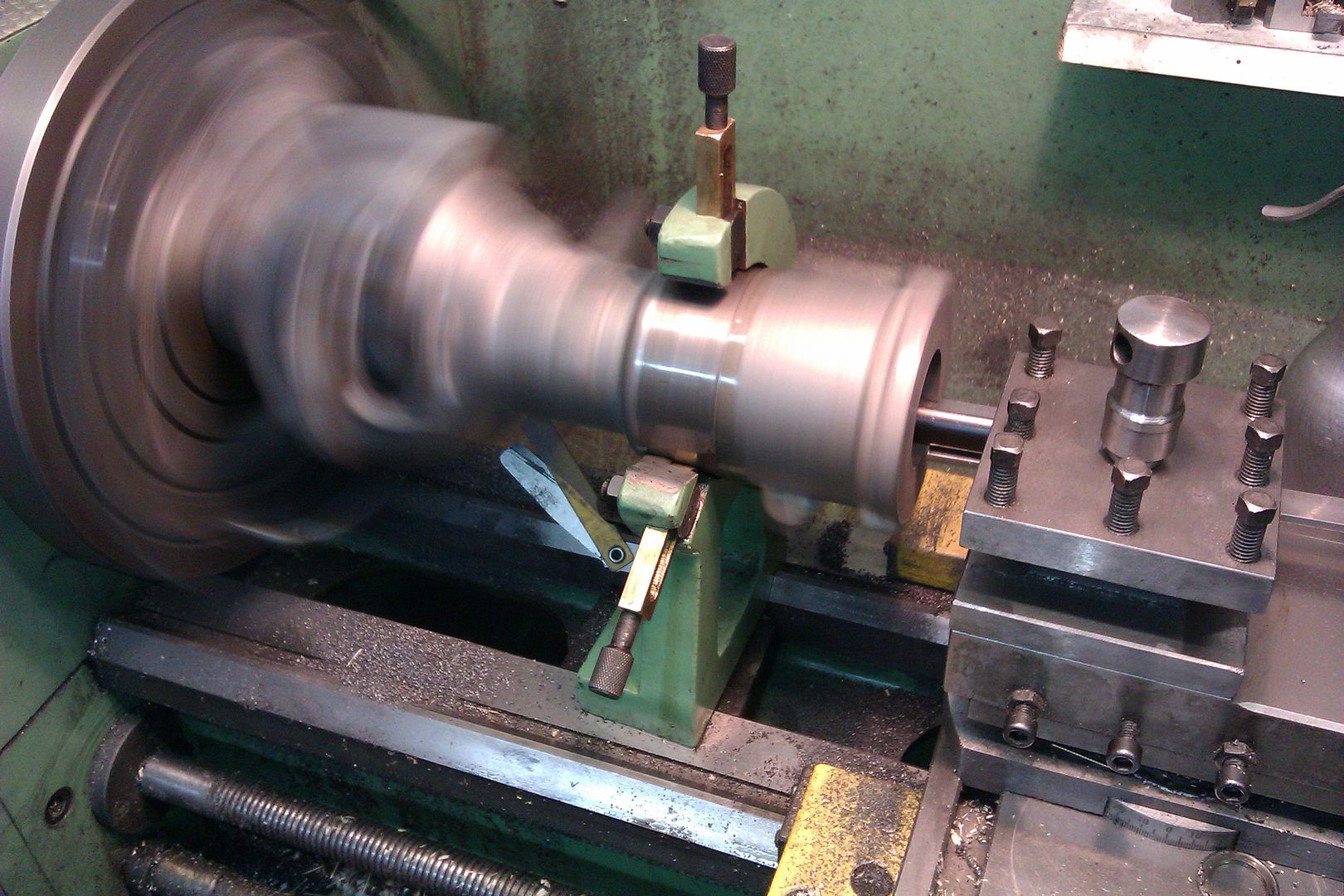

The Model B does have a fairly large centre height so, don't be overambitious when turning the longer length of the work. Better to take smaller cuts without deflecting the steady than to rush and make a scrapper.

a) you do need to clamp the work with just a short piece protruding from the chuck, and turn to finish diameter, for a length that will allow clearance for the tool behind the steady, to turn the rest of the length.

b) Set up the steady to this diameter.

c)The work should then be pulled out of the chuck far enough to to turn the length required, as the steady is moved back towards the tailstock.

d) When all is ready to start turning, clamp the steady, and then tighten the chuck.

e) Oil the fingers of the steady, and then start turning. Don't let the fingers run dry!

With a bit of care and luck, you will achieve the required result.

Howard

Neil Wyatt.

Neil Wyatt.