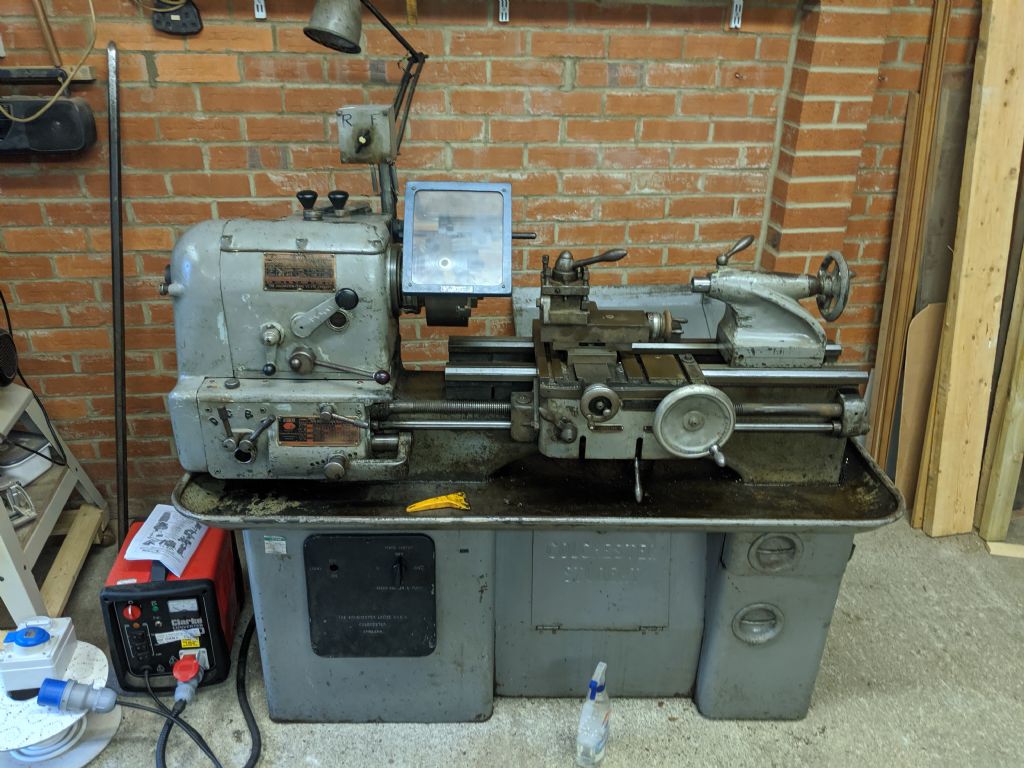

Right richard, here we go, the clearest and best wiring diagram is in the free download manual from the Colchester site, even though it is for a Mk1.5 with a different make of contactor, they are electically identical.

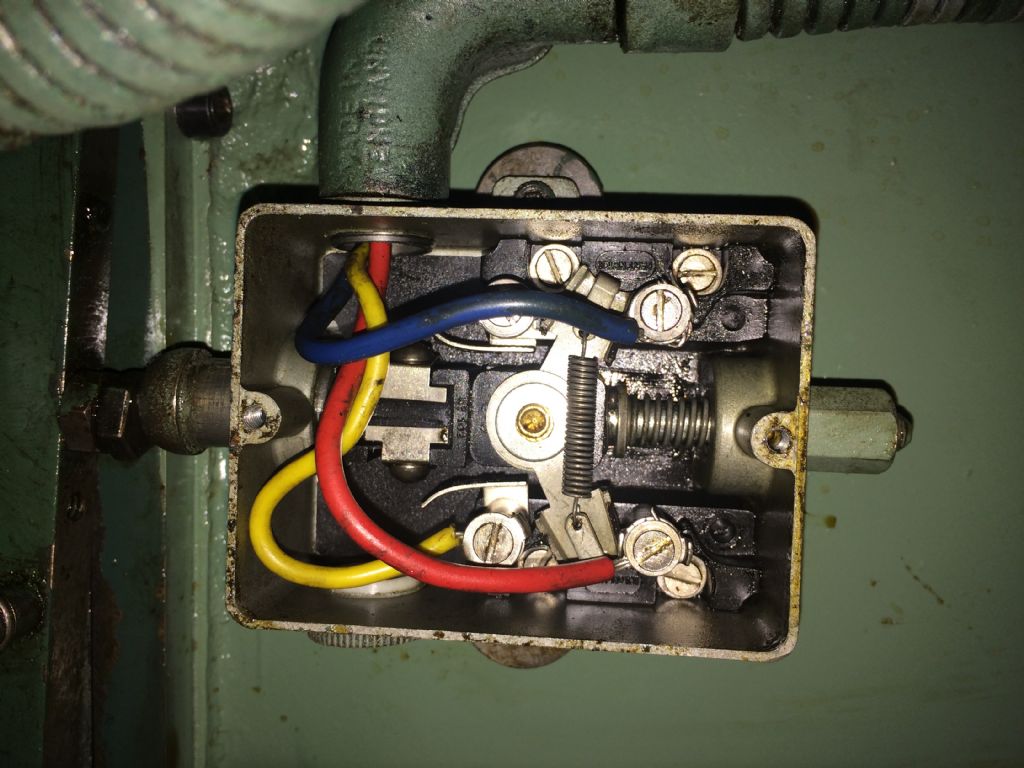

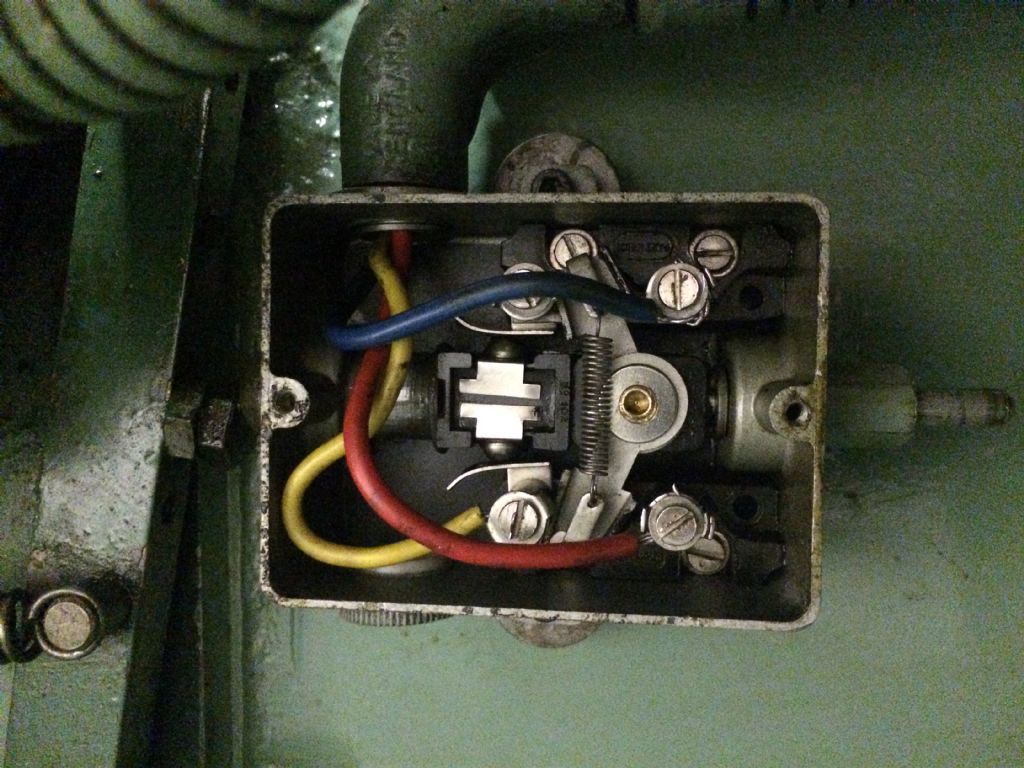

Refering to the drawing you will see what we call the limit switch (because that is what it says on the case) is referred to as the Craig and Derricot release switch.

Starting at the contactor coil, you will see that one side of the coil is connected to L1 which is an incoming phase. Remeber that the coil works between two phases, there is no neutral in this set up!

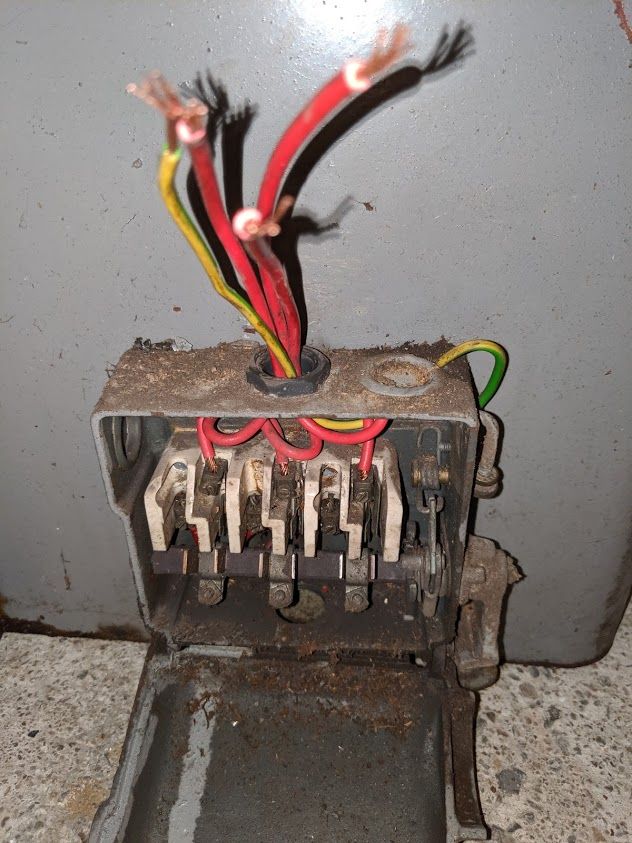

The other side of the coil connects to terminal 2 on the contactor, and then to the red wire which goes to the C&D switch terminal 3.

The other phase used is L3 which goes via a link wire through terminals 10 and 9 on the contactor, which are the overload cut out switches, and then on through the yellow wire from terminal 9, through the end cover and lock switches to terminal 1 on the C&D switch. Note a mistake on the drawing, in that the yellow and red wires which cross adjacent to terminal 3 on the C&D switch are NOT connected but the semicircle has been ommitted from the drawing!

When the end cover is fitted, and the key switch is on, terminal one, yellow wire on the C&D switch is "live".

When the switch is lifted from the off position to the intermediate position, (we will call the unmarked terminal on the C&D switch 4) 1 and 4 are connected together, and 2 and 3 remain connected. the live goes from1 to 4, down the link to terminal 2 across the switch to 3 and back to the coil on the red wire, and the contactor pulls in/motor starts.

on the contactor, the holding in contacts close the circuit between 1 and 2, and as the start handle is moved fully in to the on position, the C&D switch opens 2 and 3, and 1 and 4 remain closed. Machine is now running, and terminals 1 and 4 on the C&D switch have become part of the holding in circuit and the machine will continue to run till the contact is broken by pushing the lever to stop, or if the power fails, the end cover is removed, or the key switch is turned off.

Refer to the wiring diagram whilst reading this, as I did when writing it, or it will make no sense! My money is on the key switch being in the off position. Good luck with it, and I will still be here for any further questions you have, and any further assistance you may need,

I'll make a sparky of you yet!

Phil

Edited By Phil Whitley on 07/12/2019 18:10:45

Phil Whitley.