Hi Ron,

Just a couple of out of the box ideas.

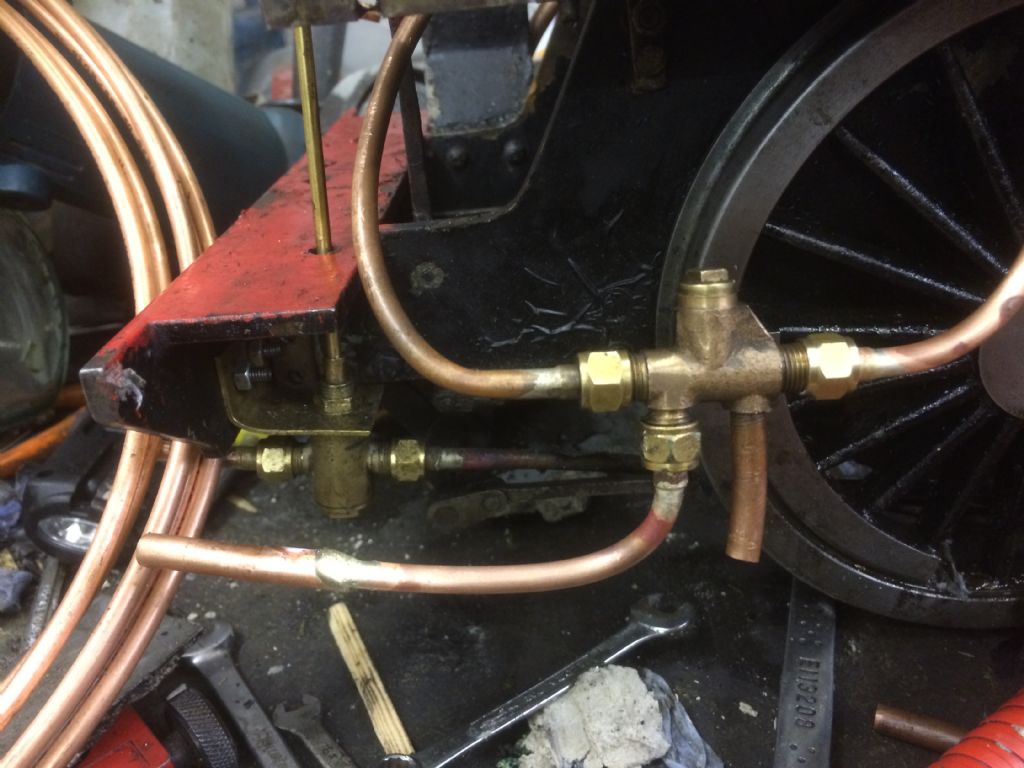

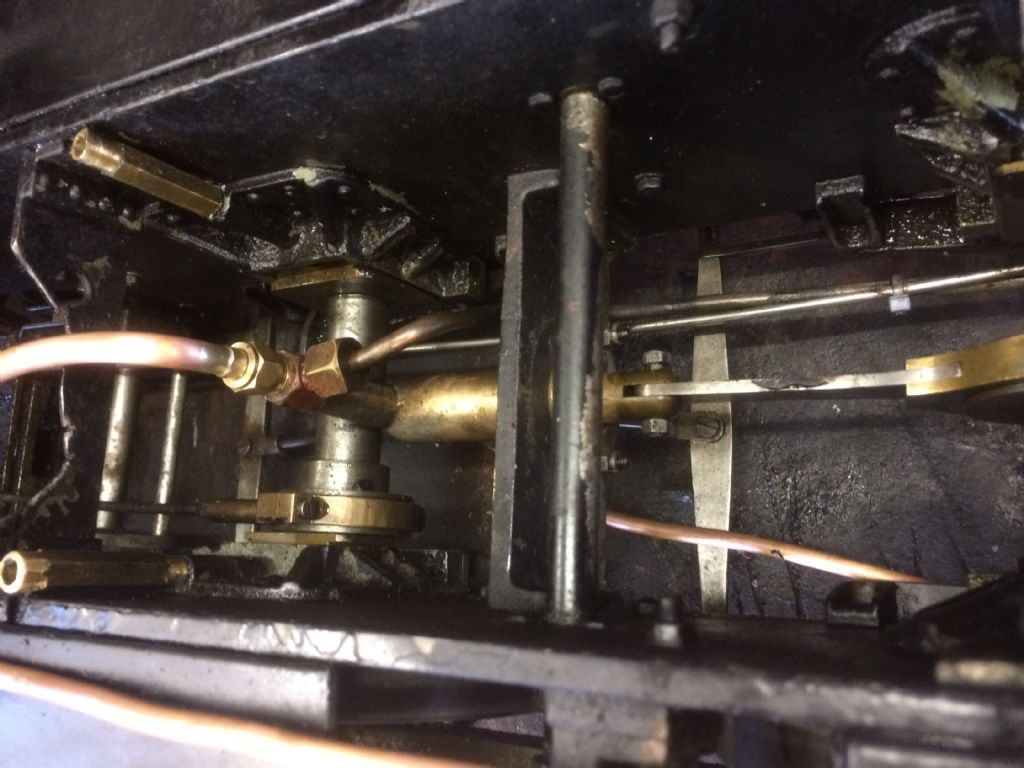

1. can you reduce the amount of check valves in the water feed system, down to one at each feed point of water to boiler?

2. I read that you have tried re-seating the balls with a hammer. This often works but not if the seat machining is bad to begin with or has become corroded, or if balls are not round or are corroded. You could try measuring the balls with a micrometer to be sure they are not more than a thou or two off spherical. For check valves the balls must be pretty round and have a smooth uncorroded surface. These days with rafts of balls and other hardware coming in from overseas there is lots of off-size parts around- even when bought as high-precision!

If the balls are corroded or are not round within a thou or two I'd say they are not fit for purpose and you should speak to the supplier about a credit or exchange. You might be able to get higher precision balls from simplybearings.co.uk or other drive parts suppliers.

You could check the seat with one of your measured, now known-spherical balls. Colour one up with a felt pen and load it in the check valve. Rotate with a short piece of rubber hose or a wood dowel with some sticky tape or putty on it. Then remove the ball and with a magnifying glass examine the seat. If it does not have an even ring of ink on it with no gaps, then it will probably leak, and needs to be dressed. If it does you could do it by machining with a D bit or lap it in with some automotive valve grinding paste on a ball. If you use the paste method don't re-use the ball used for grinding, if it is scuffed up, in the finished valve. Use a known good one.

3. If there is room in the valve you could try making a metal poppet type check valve with an o-ring to seal it, an a spring to close it, rather than a ball. Be sure to use Viton o-rings if you do this approach.

4. You could try a Viton rubber ball rather than stainless balls. I have heard of rubber balls disappearing into pipework under high pressure or vacuum though, so I would not recommend that as a first try approach.

Hope these ideas help. JD

Ron Hancock.