Ok, answering my own question here, but in the hope it may help others with the same machine, here's what I found …

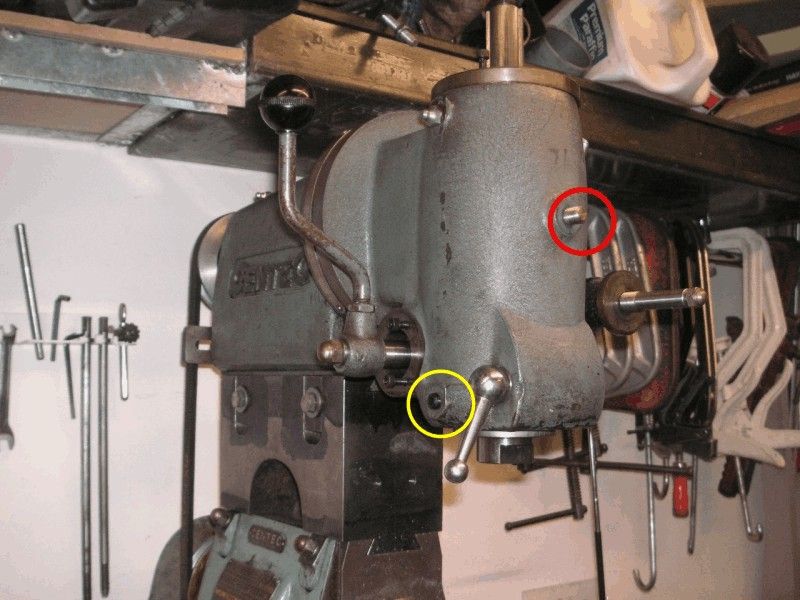

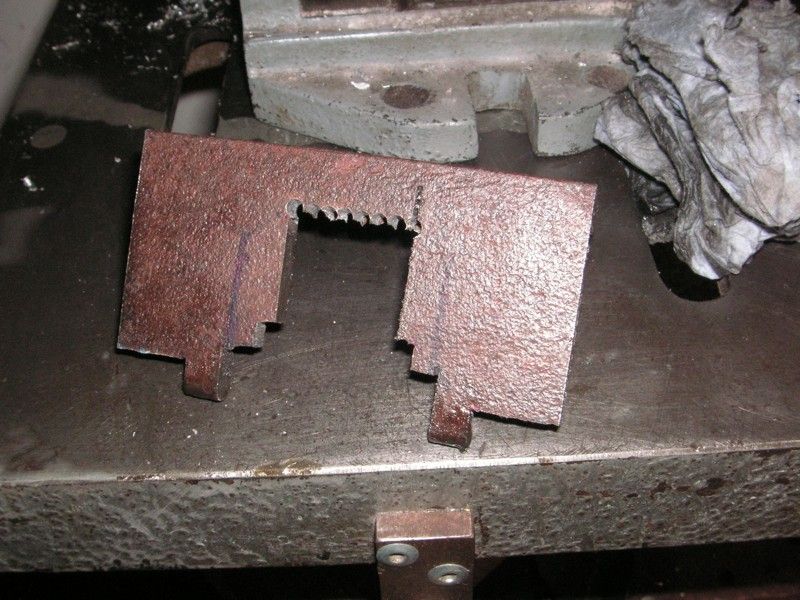

Yes, the castellated nut at the top of the quill is a left-hand thread. Given that I didn't have a mill to make a suitable spanner this is what I quickly cobbled up from a piece of 2" angle …

Pretty rough I know but with the help of a large shifter it did the job well.

Having got that off I removed the three cap screws holding the top bearing flange to the casting and immediately realised that I didn't need to remove the castellated nut.

Doh! The whole top bearing assembly comes out complete with castellated nut and bevel drive gear just by removing the cap screws …

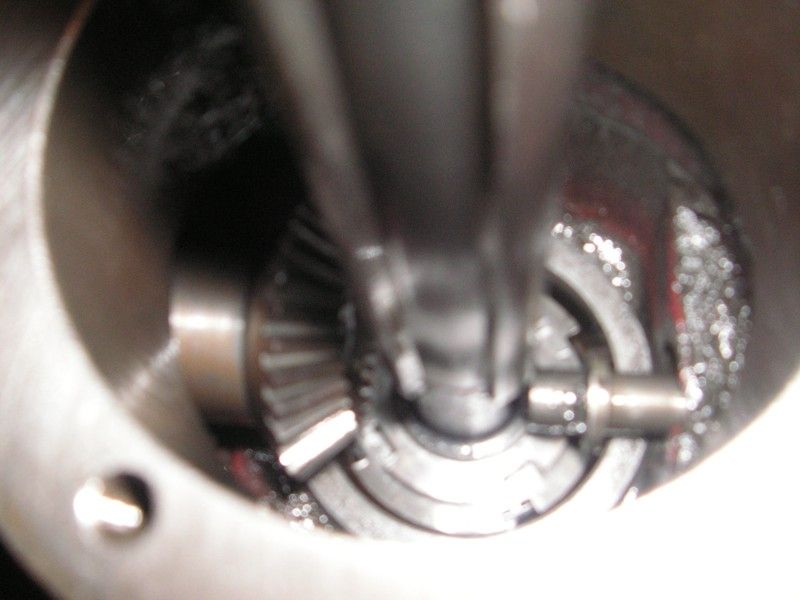

This gives access to the inner end of the mystery stud. It's an upper stop for the quill. If the quill rose any further it would hit the bevel gear on the horizontal drive shaft opposite …

Apologies for the blurred photo. I was standing on a bucket on a box and couldn't see the viewfinder, but it gives a vague idea of the arrangement.

As I hope can be seen from the photos, the stud terminates in a flange and pin. The pin acts as the stop. There appears to be no mechanism to stop the stud turning, strange given that mine was fitted with a dome nut. Keith, I will indeed employ your suggestion of the screw driver slot and use a standard nut (although bringing the quill hard up against the stop seems to have a similar effect). There's no chance of the stud falling into the head as it hits the vertical quill drive so, provided you don't run the machine with the nut removed and stud pushed in, you can't loose it or do any damage.

Julian Palmer.