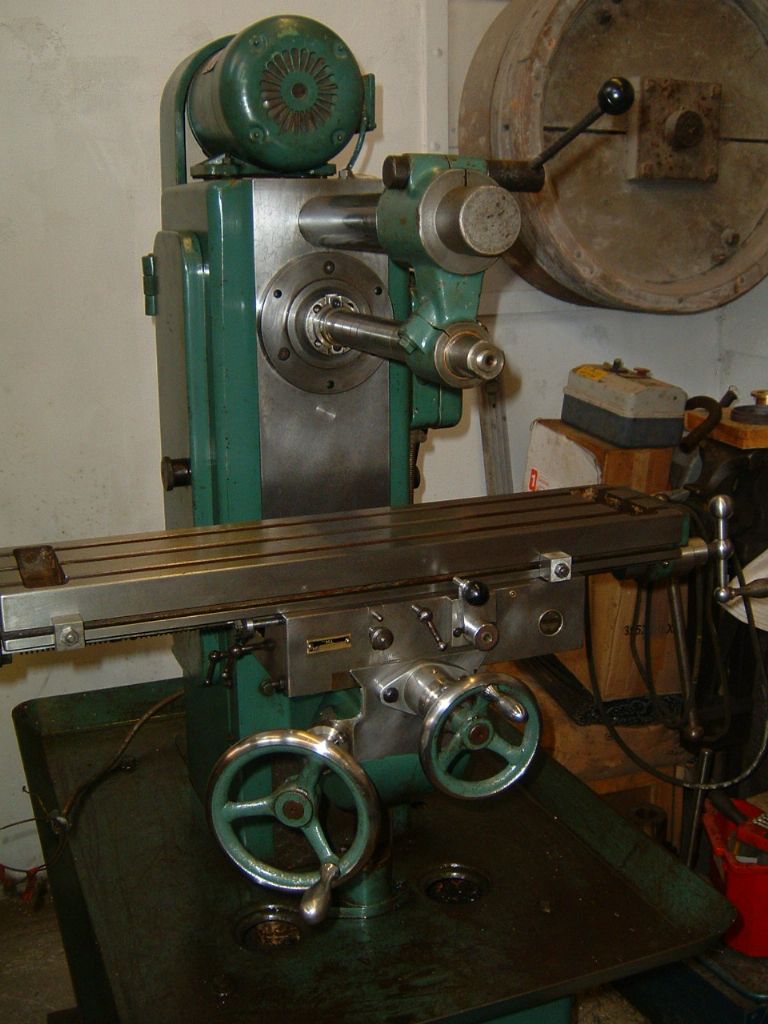

On a side note …. They think the Centec 2 is just a plane old keyway cutter …..who am I to disagree if you get my drift

I agree on that one! Only good for cutting keyways, grooves, (square, oblong, round, narrow, wide or even involute).

Those 'grooves' could just as easily be full width of the feedstock, as well!

Of course, one would not really consider it for anything other than keyways – slab milling, gear cutting, profile milling (multiple cutters in fixed relation to one another) would be out of the question.

Also not needing to take small cuts at a time (thus making jobs that much faster to complete without multiple finishing cuts) could not possibly be seen as an advantage?

No, you don't really need an arbor with support at both ends, for 'long overhang' cuts, do you? Won't make slitting saws easier to use successfully either! I suppose!

Yes, definitely only useful for keyways, nod, nod, wink wink!

On a serious note, the only downside I see would be the extra cost of new cutters (slab mills, over fly cutters for the vertical mill, per eg). But there is lots of cheap tooling available second hand – because horizontal milling machines are so 'out of favour'.

Oh! So it can easily be converted to a vertical mill as well? Whatever next?!?

not done it yet.