Posted by AdrianR on 10/06/2020 19:42:21:

…

Does anyone definitively know the angle as I have seen some other forums arguing what the angle is.

Adrian

Not found a definitive 'R8' yet! It's not in my copy of Machinery's Handbook (20th Edn), which led me to assume R8 was just ANSI Standard Steep Machine Taper, 3½" to the foot, or 16.2602°. Not so!

Tubal Cain's Model Engineer's Handbook 3rd Edn and this link quoted as a Wikipedia reference both give 16 degrees and 51 minutes, which is 16.85° in decimal money. Tubal Cain and Wikipedia's Bridgeport collet drawings differ slightly, but the angle is the same. I think 16.85° is trustworthy.

R8 probably isn't in Machinery's Handbook because it's not a standard taper. (ie not recognised by ANSI, BS, DIN, ISO or other standards body.) Rather R8 started as a proprietary Bridgeport taper and since the patent expired has survived due to the wide popularity of the well-known Bridgeport milling machine. The rest of industry looks to have standardised on 3½" to the foot, but there are lots of different formats.

R8 doesn't seem to have any particular merit as as a home workshop taper. It's a quick release type not that different to the International Standard steep taper. Looking at the drawings R8 collets are lighter with a smaller gripping area, ie not so strong. I'd guess being smaller and lighter suits smaller mills better than the hefty standard collets found on machines bigger than a Bridgeport. Does R8 have any advantage over MT on a hobby sized mill other than quick release? I doubt it!

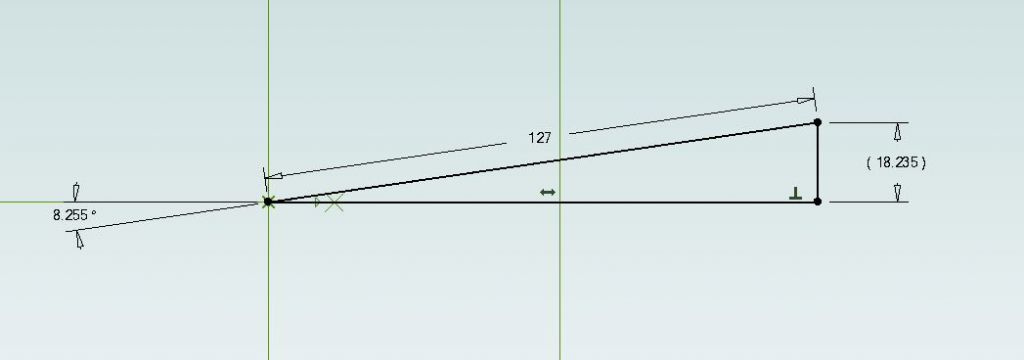

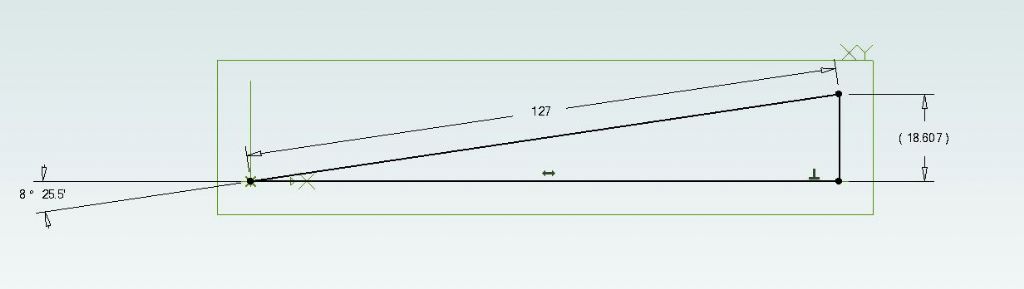

Confusion abounds, but my figures agree with Jason's. A 5" sine bar should be lifted by 18.607mm ( 0.7325" ) to set a taper half-angle of 8.475°

Have to say I found the maths quite error prone. Specifying angles in degrees, minutes and seconds is 'difficult' compared with decimal degrees. As most calculators work in radians, there's a few conversions to get wrong or forgetting to set the machine correctly. 16°51' = 16.85° = 0.2941 radians. After remembering to divide the angle by two, then recall from soh, cah, toa that the wanted height is 'o for opposite', hence height = sin(angle) X length of sine bar. Just to add to the fun, given a 5" sine bar, Jason worked in millimetres, same as me. I also used QCAD to check the result; I can't think of a quicker or safer way to get the answer. A human friendly drawing plus a computer doing the sums is hard to beat.

Why is nothing ever easy? Doesn't help I spent so many Maths Lessons staring out the window thinking about girls…

Dave

Edit: pesky smileys!

Edited By SillyOldDuffer on 11/06/2020 10:56:49

old mart.