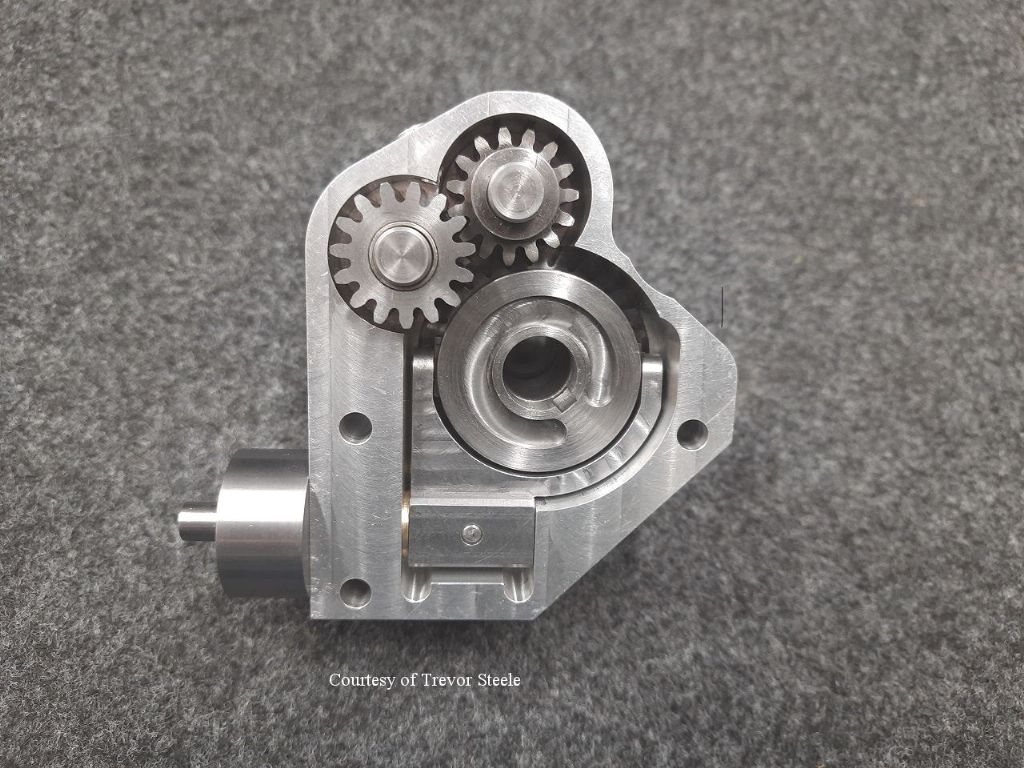

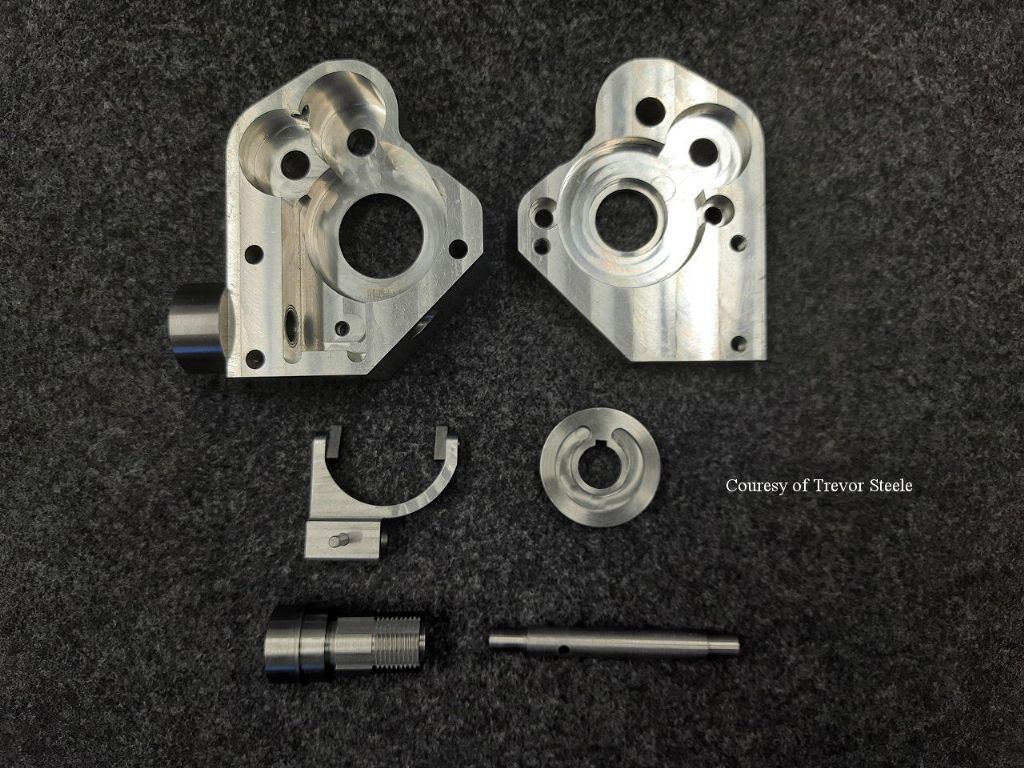

Trevor has indeed made a very nice job of this.

The bolt on nature of the brackets rather than having integrated castings are the only thing that show its a modification, not factory fit.

From experience with my Pratt & Whitney B 12 x 30, which has a single tooth dog clutch as standard, I'd say that making the stop dogs with an integrated fine threaded adjuster has advantages when needing to set up just so. On the P&W simply sliding the dog along the rod becomes finicky when the longitudinal stop position needs to be set to significantly better than about 50 thou / 1 mm. I generally use an old set of gauge blocks that no longer wring together for setting the throw out position. Of course the P&W is a bigger, heftier, machine with 45 or so years of use under its belt so operation isn't factory fresh. Its quite noticeable that the exact clutch operating point varies a few thou with speed. Both rotational and longitudinal.

Although Hardinge claim their version of the screw cutting clutch is good up to 1,000 rpm both P&W and Holbrook agree that around 300 rpm is quite fast enough thank you. I found my first few times of screw cutting at that sort of speed was a little buttock clenching until I learned to trust the clutch. Maybe 8 tpi was a bit coarse to start with! The P&W throws out with a very positive "Bang" too. Frankly, up to a point, faster is better.

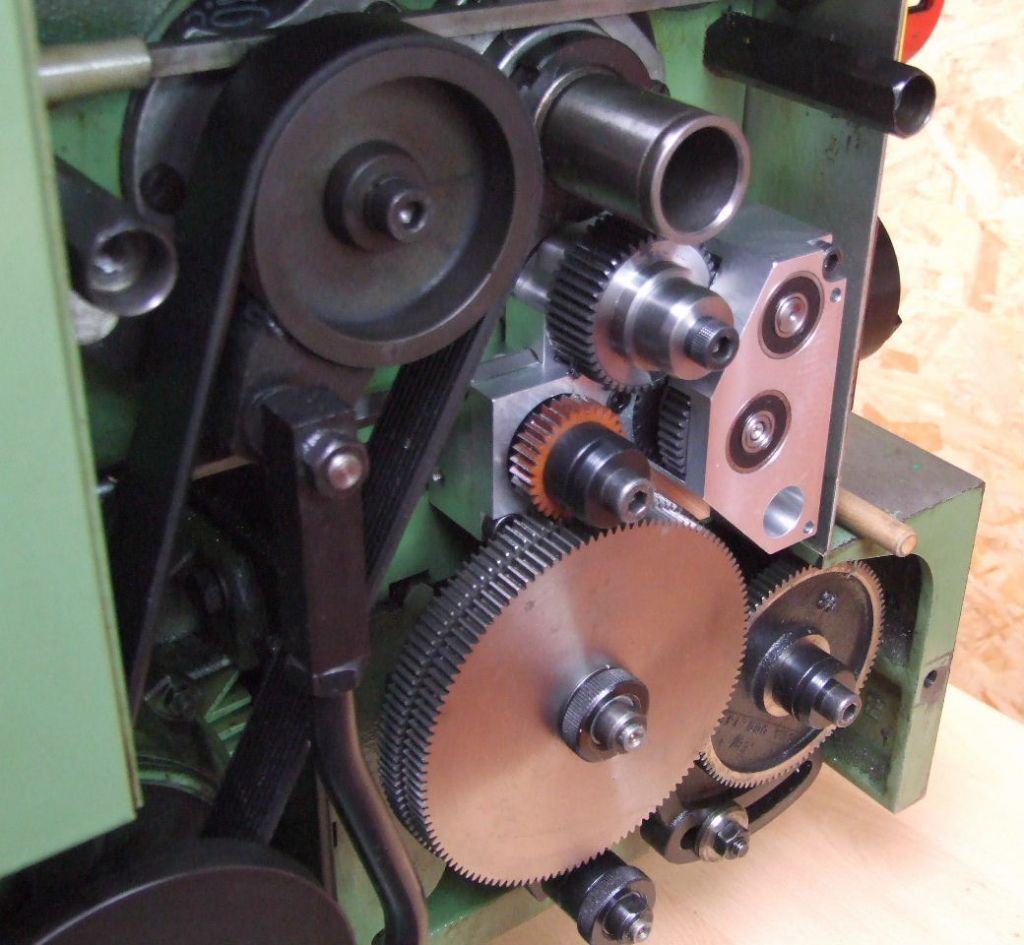

It appears that Trevor keeps the metric / imperial conversion pair permanently mounted so he only has to change the gearbox input gear and put the the spacer on the other side when switching from one standard to the other.

A most excellent idea which should be mandatory for anyone having to handle both metric pitch and imperial tpi. I did a similar thing many years ago on my Smart & Brown 1024. My only regret being not doing it the first time I had to switch rather than waiting until the fourth!

Time to take another look at the 1024 to see if there is any way of getting such a clutch in by taking Trevors version as a starting point.

Clive

Edited By Clive Foster on 15/02/2021 15:41:40

Graham Meek.