Boring copper tube problems

Boring copper tube problems

- This topic has 21 replies, 16 voices, and was last updated 20 April 2017 at 23:53 by

nigel jones 5.

Viewing 22 posts - 1 through 22 (of 22 total)

Viewing 22 posts - 1 through 22 (of 22 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

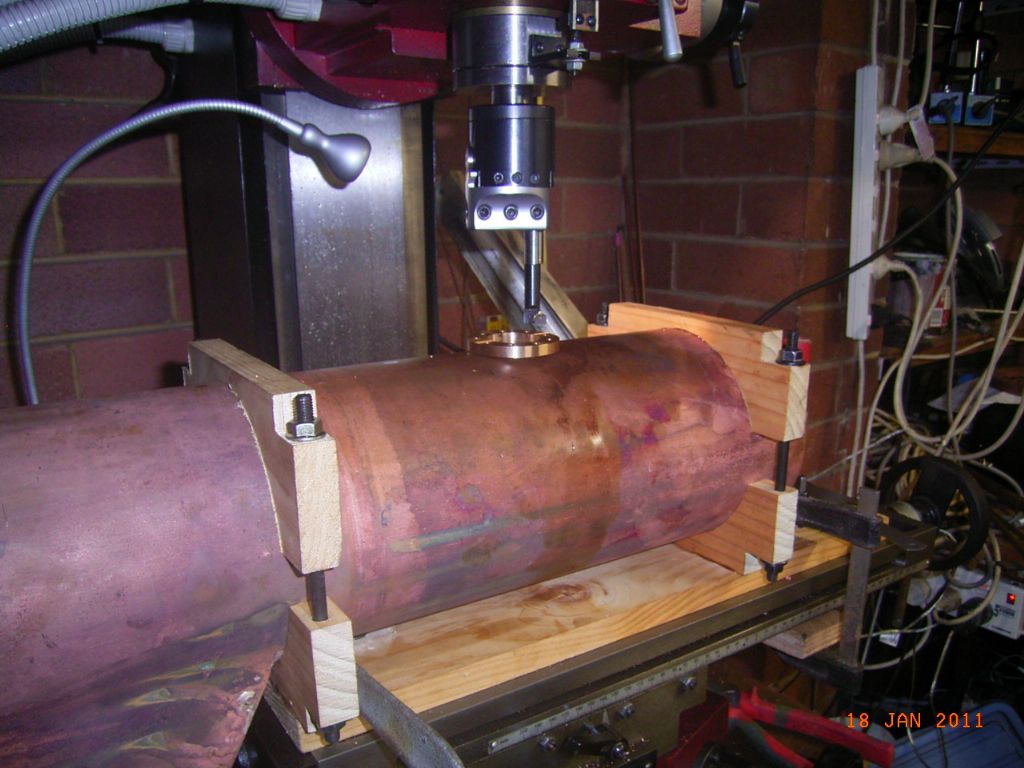

copper tube. I use a stepper drill and then a boring head to go to 1.5". Thing is I am having great difficulty in achieving this as the mill simply doesn't have quite enough torque. My mill is the X2 500w brushed motor. I converted it to belt drive which made things a lot worse as it ups the head speed! I reworked the pulleys to give the lowest gearing I could but the machine still stalls easily. Obvious solution is a bigger mill but I haven't seen anything second hand between mine and a full size Bridgeport type which I simply don't have space for – are there any cutters which would make lighter work of cutting/boring copper using an indexible boring head? I already use milk but it doesn't make much difference.

copper tube. I use a stepper drill and then a boring head to go to 1.5". Thing is I am having great difficulty in achieving this as the mill simply doesn't have quite enough torque. My mill is the X2 500w brushed motor. I converted it to belt drive which made things a lot worse as it ups the head speed! I reworked the pulleys to give the lowest gearing I could but the machine still stalls easily. Obvious solution is a bigger mill but I haven't seen anything second hand between mine and a full size Bridgeport type which I simply don't have space for – are there any cutters which would make lighter work of cutting/boring copper using an indexible boring head? I already use milk but it doesn't make much difference.