I've done some experimenting with telescopic gauges to see how accurate I am with them, and although it's not terribly scientific (I'm not working in a metrology lab with the resources to arbitrate on measurements to tenths of a thou) I would offer the following.

Firstly I measured a bore of about three inches with an internal micrometer. I could do this to a repeatability of about +/- 2 – 3 thou, as my ability to apply the same force to the micrometer barrel consistently was the limiting factor, though getting the micrometer straight across a diameter of the bore was also fiddly and variable. Taking successive measurements just taught me that I was a hopeless case and wasn't getting better.

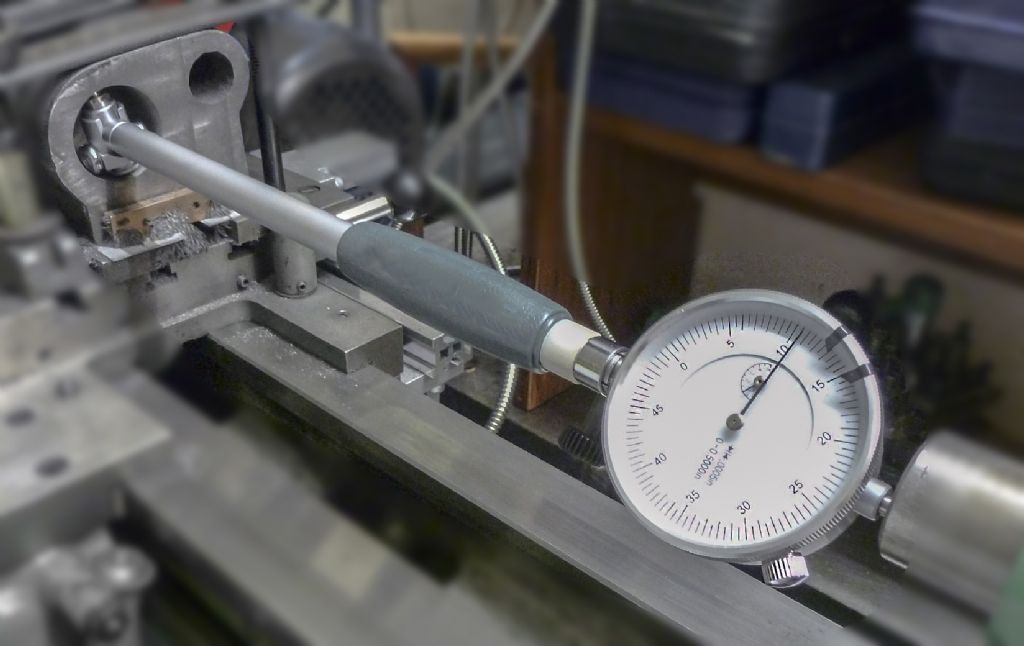

I then tried telescopic gauges, in my case the Moore and Wright ones, though I do have some Starrett ones.

I found my measurement was immediately at least as repeatable, and with practice I got better in that the measurement I made with an external micrometer was also about +/- 2 thou repeatability initially, but I got better with practice which I didn't with the internal micrometer.. As the process of making a measurement with a telescopic gauge means making two measurements – one to set the gauge to the bore and another to measure the distance across that gauge – there is scope for more variation than a direct measurement. But using the telescopic gauge was more repeatable than the internal micrometer – at least in my hands. After some practice (I was boring a hole for a bearing) I was fairly confident my bore measurement was repeatable to about +/- 0.5 thou. Some of my gauges are in better nick than others, and it also depends to some extent on being well within the working range of the gauge, but that just taught me to be careful that my telescopic gauge was working properly.

Measuring the same bore with a digital caliper is revealing – the caliper may have a resolution of 1 thou but it sure ain't that repeatable.

I also have tried the same experiment with smaller holes within the range of a Starrett internal micrometer of the caliper kind (model 700) and find this is more repeatable, typically +/0.5 thou or may be a bit better, but of course this only measures the mouth of the hole and says nothing about the bore.

I've been careful to talk about repeatability, as I don't have anything I could actually say was calibrated to give an absolute accuracy.

HTH Simon

CHARLES lipscombe.