If we believe MEinT’s figure for proof stress 4830 psi (please stop calling it yield), then boiler shells built to all the other criteria will all take on a permanent swelling at 2* pressure test, where they could be at 8000 psi (JasonB’s working stress of 4000 psi * 2). I’ve never seen one, and I’ve been involved in model engineering for 40+ years. It would be obvious, as the end near the tube plate is reinforced and so would not permanently deform. I’ve found another figure here which is for C12200, which claims to be equivalent to C106, which is what we in UK will use. It quotes 0.5% proof stress at 10,000psi. My figure was 0.2%, so I’d expect it to be a bit lower. As others say it wouldn’t matter if you did get some permanent set, but UK national standards are built around staying below proof stress.

If we adopt MEinT’s figure, all we achieve is more expensive boilers, not more safe. I very much hope that subsequent instalments of this saga will remain in the unused pile.

Duncan, I do apologise for not responding until now but I have been on a trip to Hong Kong for my son’s engagement party and whilst there it was a delight to travel on the old trams, a British legacy from 1904.

It’s one of the few tram systems in the world that has continuously operated electric double-decker trams since its inception.

Against a back-drop of modern high-rise skyscrapers it reminded me of the Luddite movement that began in 1811 in Nottingham who organized raids to destroy the machines and sometimes factories themselves in resistance to industrialization and technological change.

Much like the Luddites who, sadly, seem to dominate the model engineering community today – at least on this forum.

Don’t get me wrong, Duncan, I’m all for preserving our wonderful industrial revolution by making working models from the period – I’ve built a half-sized Little Samson Traction Engine traction engine here in Thailand just for example – but I used CAD to make drawings, not a drawing board, Tee square and set square, I used Excel to do calculations not a slide rule, although in my teens those were only the implements available.

So if we are to base our modelling techniques on those available in the days when our prototypes were made, we should throw away our DROs, throw away our digital callipers and go back to dials and verniers.

That, I’m sure you’ll admit is a retrograde step. As is adherence to the so-called UTS method of calculating boiler shell thickness. The UTS method is outdated, illogical and just plain wrong. Anyone who supports it it is either stupid, uneducated or has a ‘political’ agenda, and I’m including biased moderators on this forum in this category.

Now let’s get to answering your technical points.

Quote: “If we believe MEinT’s figure for proof stress 4830 psi (please stop calling it yield)”

You don’t have to ‘believe MEinT’s figure for proof stress 4830 psi’, In our article we presented a range of figures for the yield point of annealed copper and gave the urls of the sources. We chose 4830 as being representative of published figures. The boiler designer can chose whatever figure he/she believes is appropriate.

Quote: “It quotes 0.5% proof stress at 10,000psi. My figure was 0.2%, so I’d expect it to be a bit lower.”

What is it then Duncan? 0.2% or 0.5%? Seems you can’t make your mind up. The FACT is that annealed copper dose not have a precisely defined ‘yield point’, as does, say steel. The value varies greatly (as stated in our article) which is why we chose to call it the ‘yield point’, because the yield point is a readily understood term but cannot be precisely defined for annealed copper.

Indeed when you say “(please stop calling it yield)” all the website references that we gave in our article use that exact phrase ‘yield point’. If you have an issue with this go and complain to the websites not to me.

Quote: “but UK national standards are built around staying below proof stress.”

Precisely. And this answers the stupid question being thrown around on this forum about ‘why is is it necessary to avoid distortion’.

Quote: “I very much hope that subsequent instalments of this saga will remain in the unused pile.”

Luddite. Go back to your slide-rule.

By the way, much to your chagrin and that of a certain ‘moderator’ (= agitator) I’m now back and ready to answer any further technical questions you may have about the correct way to assess model copper boiler shell thicknesses.

Quote: “I’ve been involved in model engineering for 40+ years”

So what?

Quote: “involved in model engineering..”

‘Involved?’ What does that mean? Simply reading a magazine means you are ‘involved’.

In contrast I have been making models for well over 60 years. I built an LBSC 3 1/2″ gauge Juliet chassis when I was 16 years old.

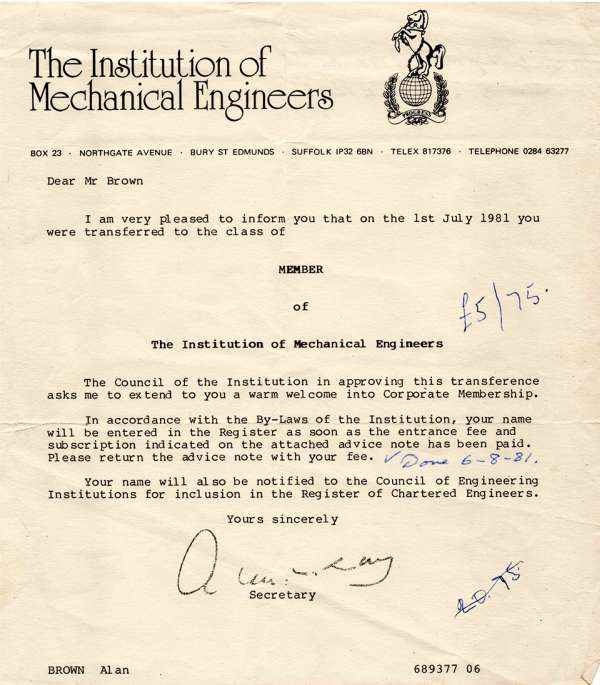

I’ve been a Professional engineer for 44 years. (Certificate below).

I’ve moved with the times – you seem stuck in the past.

I’ve got a drawer full of certificates covering for example steam boilers, pressure vessels (welding procedures ARAMCO – Saudi Arabia), I have a Collier’s Mechanical Engineer’s Certificate, and was a member of the Chartered Institution of Building Services Engineers (MCIBSE) (as well as MIMechE) until I retired. I’ve designed, specified and installed steam boiler installations up to Megawatt capacity. Think I don’t know a thing or two?

PS NO ONE has addresses my previous comment that the AMBSCE code (Australian Miniature Boiler Safety Committee Code pt. 1. Copper boilers, issue 8, 2012) uses the Yield Point of annealed copper and not the the Ultimate Tensile Strength of un-annealed copper modified by arbitrary factors (called ‘safety factors which clearly they are not) in their Tables.

Please explain why you would accept the modern AMBSCE code based on the Yield Point Method, but still cling on to the irresponsible UTS method.

Paul Kemp.