Ron, you are everyones hero, and like any hero you deserve a rest before picking up the tools again !

Truly, there is nothing too wrong with that loco if the chassis runs on air and the boiler raises steam.

Now the problem seems to be getting water into the boiler, reliably.

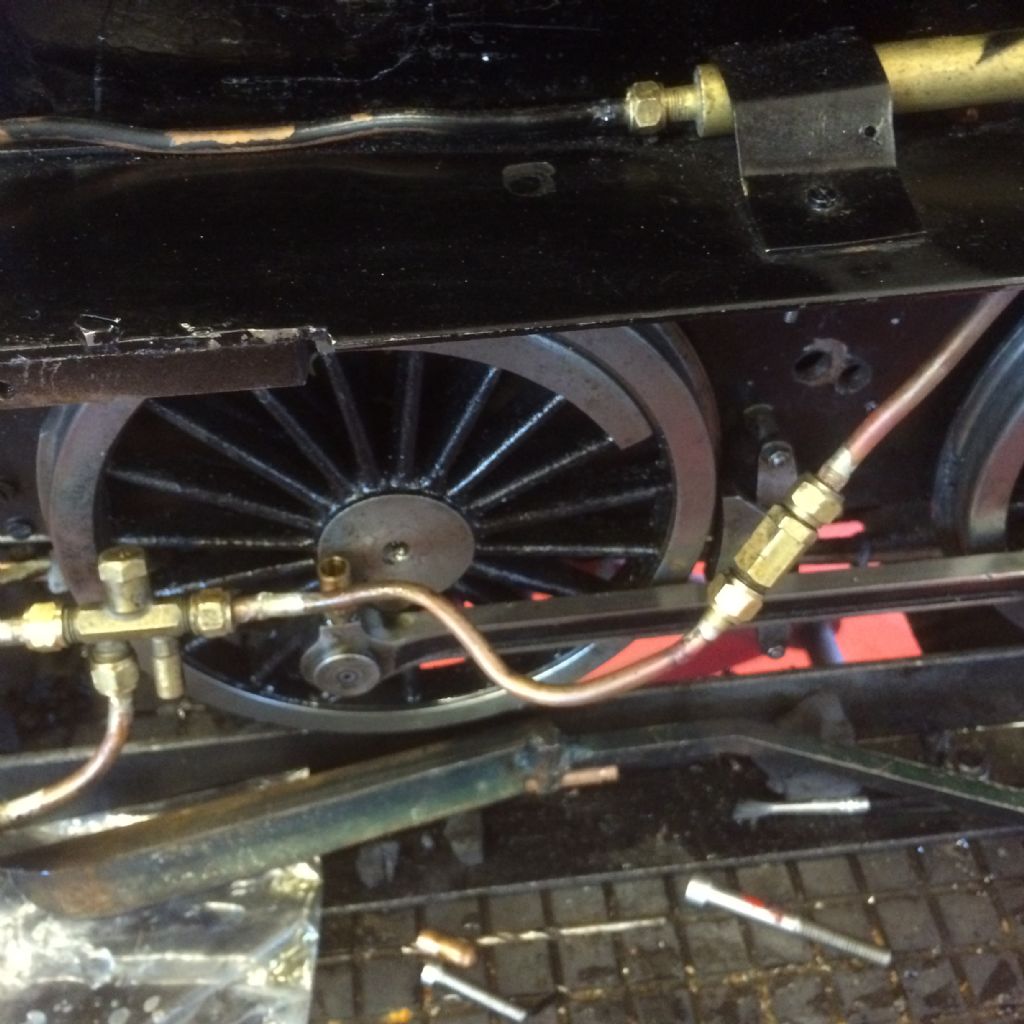

Just a thought, but I think you have introduced too many non-return valves on the routes into the boiler.

Perhaps thinking that at least one will work. Not good.

Check the boiler mounted clack valves all work , on the bench.

Take out any other clacks you have added ( that are not needed).

Just get your confidence back by making sure the hand pump circuit works.

Then then the axle pump / bypass circuits work.

Ask one of the club members to try the injector on one of their locos, it is the only way to find out if it works,

unless you have steam raising kit in your workshop.

Keep the pipework simple and well sized.

Can understand your disappointment Ron after all your effort , very slowly this time, lots of cups of tea

between each item checked . Try it, one step at a time, slowly.

We all want you to succeed Ron.

Ron Hancock.