I have just looked at the link posted by Nick, and was surprised to see that the small Record bench drill shown was just a Far Eastern machine.

I remember that 15 – 20 years ago Record used to produce their own bench and floor standing drill presses, what ever happened to those? They were the usual Record blue with hexagon shaped tables and excellent castings. One of the three Tabwell Tools shops in Bakewell used to stock them.

Record had an advert out at the time that showed close up photos of the inferior details of an imported drill press against their own product.

On the whole though I think the Far Eastern drills work fine and are mostly worth the money. Last time I looked you could buy a floor standing machine with a two morse taper and sixteen speeds for just over £200. The few that I have used have been fairly quiet and smooth running.

Alright, they can flex a bit with their thin light castings, particularly the casting that supports the table, and the quills are a sloppy fit on most of them. But they are just a drilling machine and most are light years better than a noisy Black & Decker hand drill clamped in a drill stand.

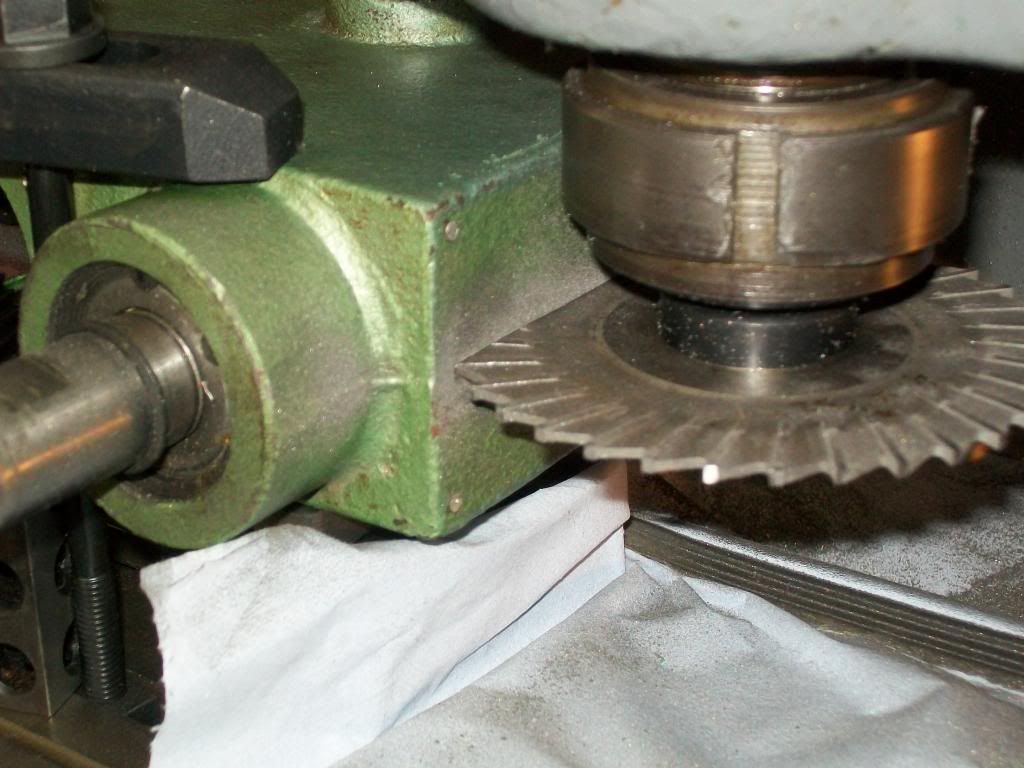

Having said that, I have just been using my Elliot Progress 2G back geared pillar drill, what joy! Although I do wish it had a rack and pinion rise and fall table like most of the Taiwanese and Chinese machines do. I must get the new three phase motor and VFD fitted that I bought a few years ago.

Edited By Lathejack on 29/01/2015 18:15:01

Mike Poole.

Mike Poole.