Not done it yet?

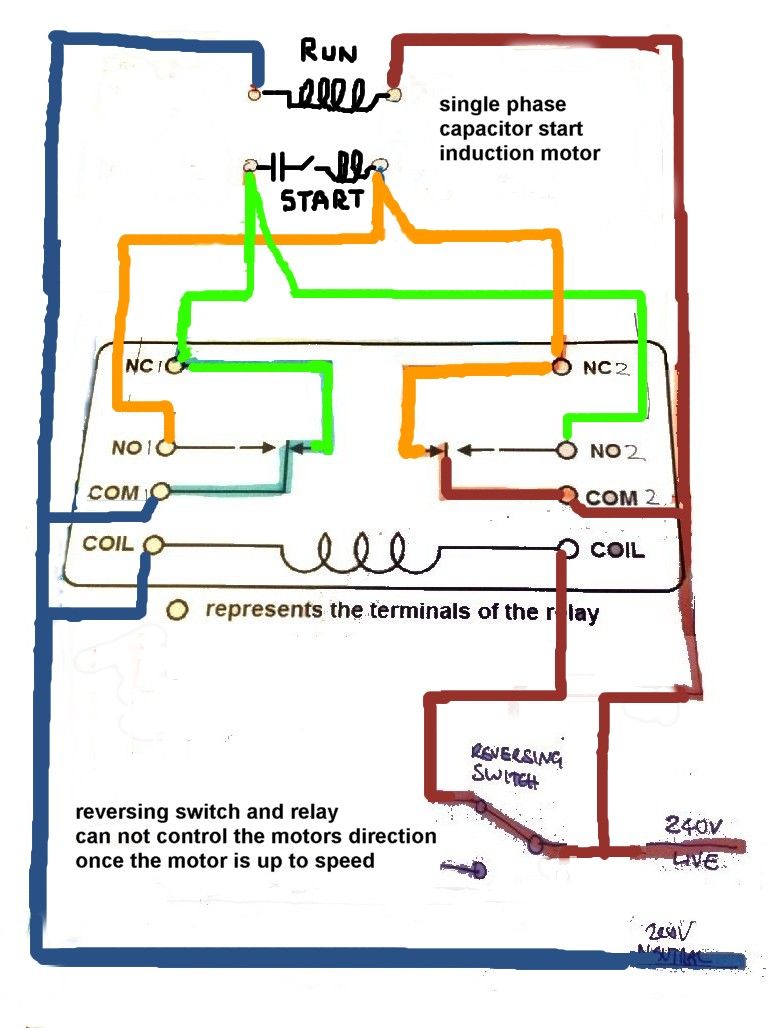

All the start winding does is push the rotor in the same direction every time, and provide extra power to overcome the starting load

There is bound to be a slight (at least) difference in speed at which the start windings are turned off for forward or reverse. The rotor is accelerating at the time, so the resulting force on the switch will be different, dependent on which direction of travel. Physics fact!

The centrifugal switch is concentric with the motor shaft, works on the same principle as a bob weight governor and will operate at exactly the same speed in either direction. If you think this is not the case, please explain WHY?

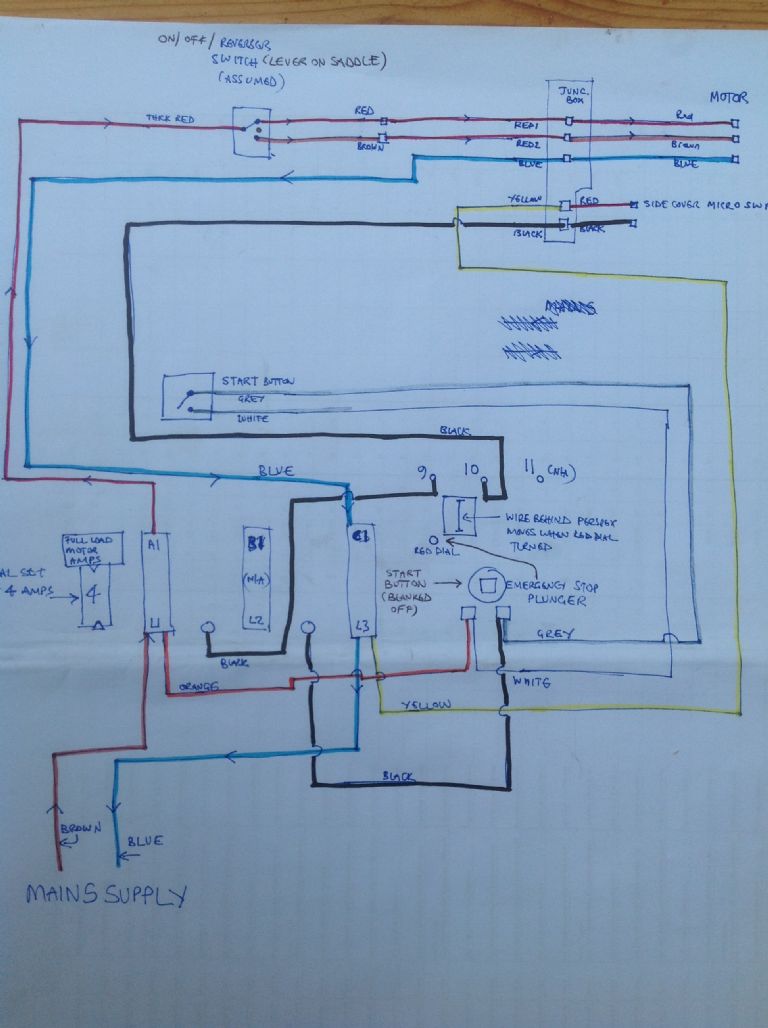

I still think that fault is caused by the run winding being out of circuit in that direction

If that were the case, please explain how the machine works OK at lower speed settings

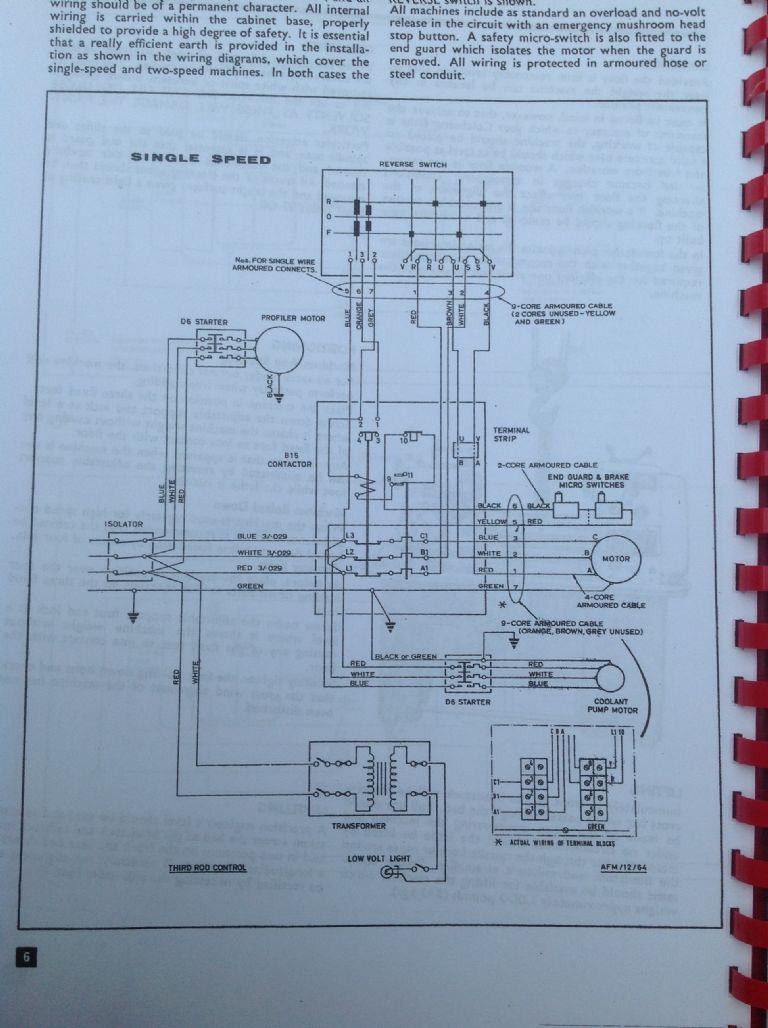

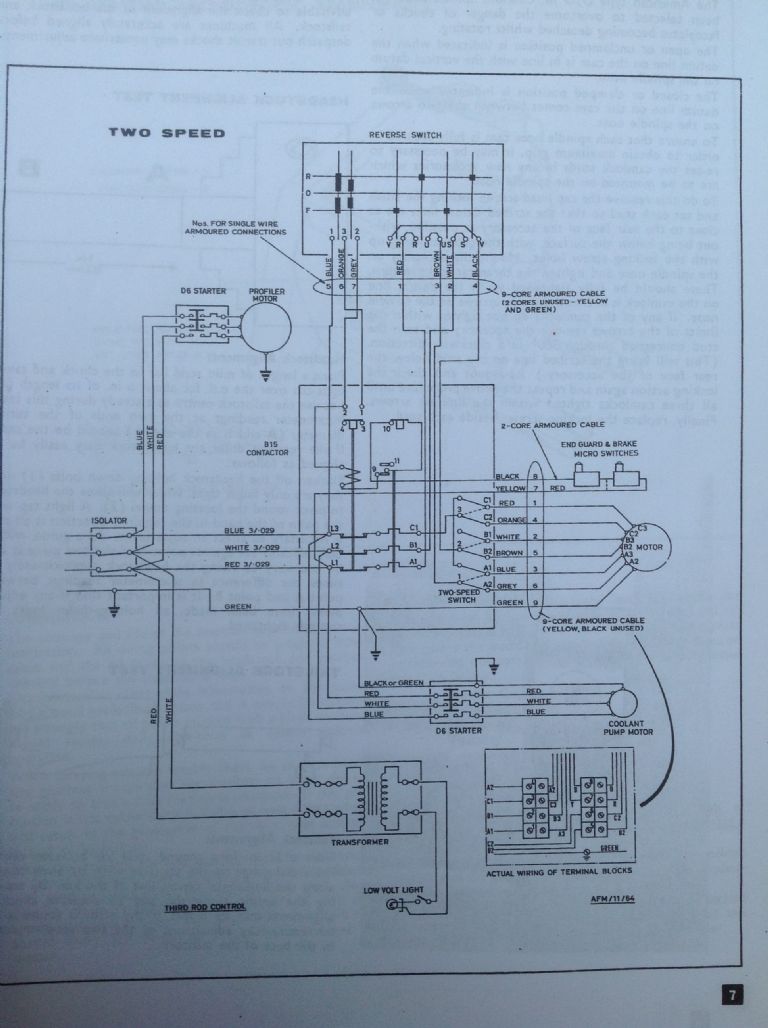

Because at lower speed setting there is less rotational resistance due to the gearbox, and less vibration. To cut a long story short, when the fault occurs, the motor is behaving exactly like a centrifugal switch motor with an open circuit run winding, but we know the run winding is not open circuit, as it runs perfectly on the same winding in the other direction, leaving us to come to the conclusion that the fault lies in the switching or reversing circuitry. I did say it was an "interesting" fault.

Ken Price 1.