Martyn and Jon,

I think there is some confusion here, which I would like to correct if I may.

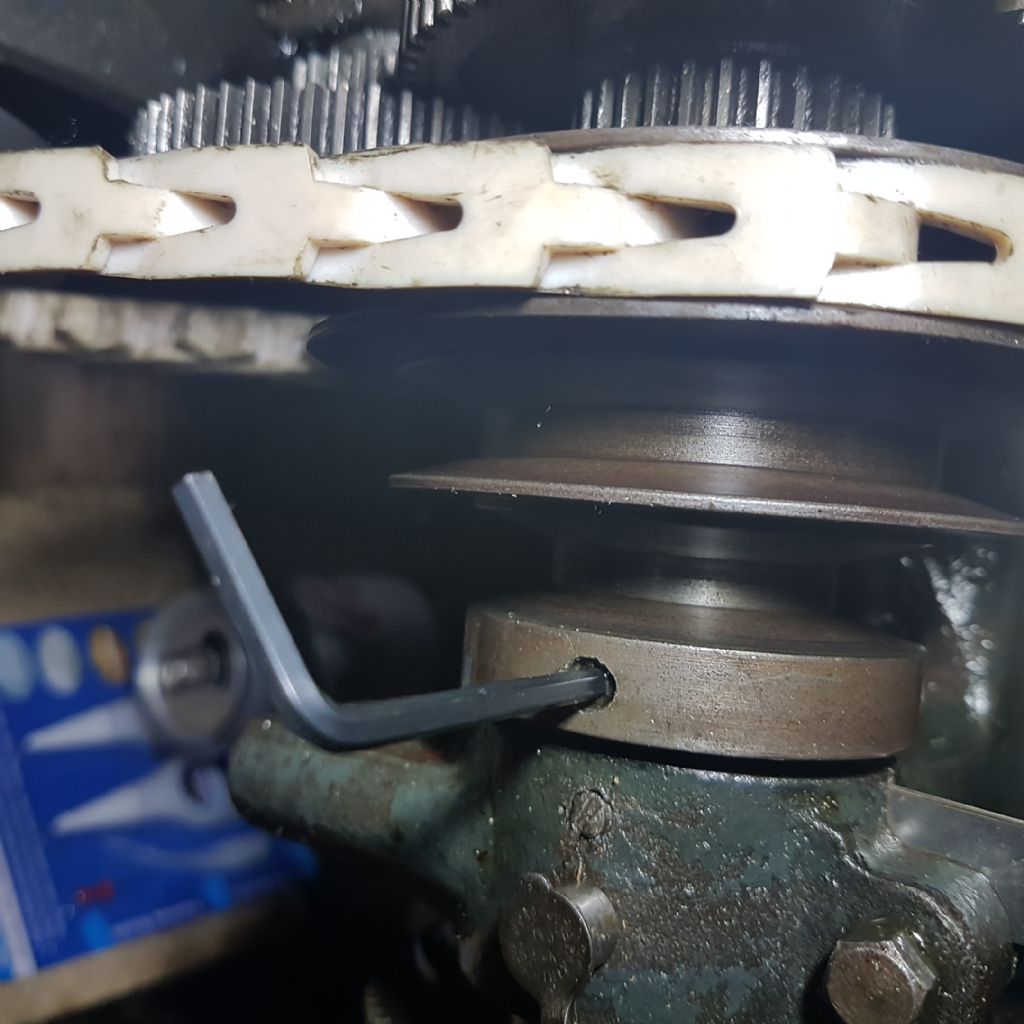

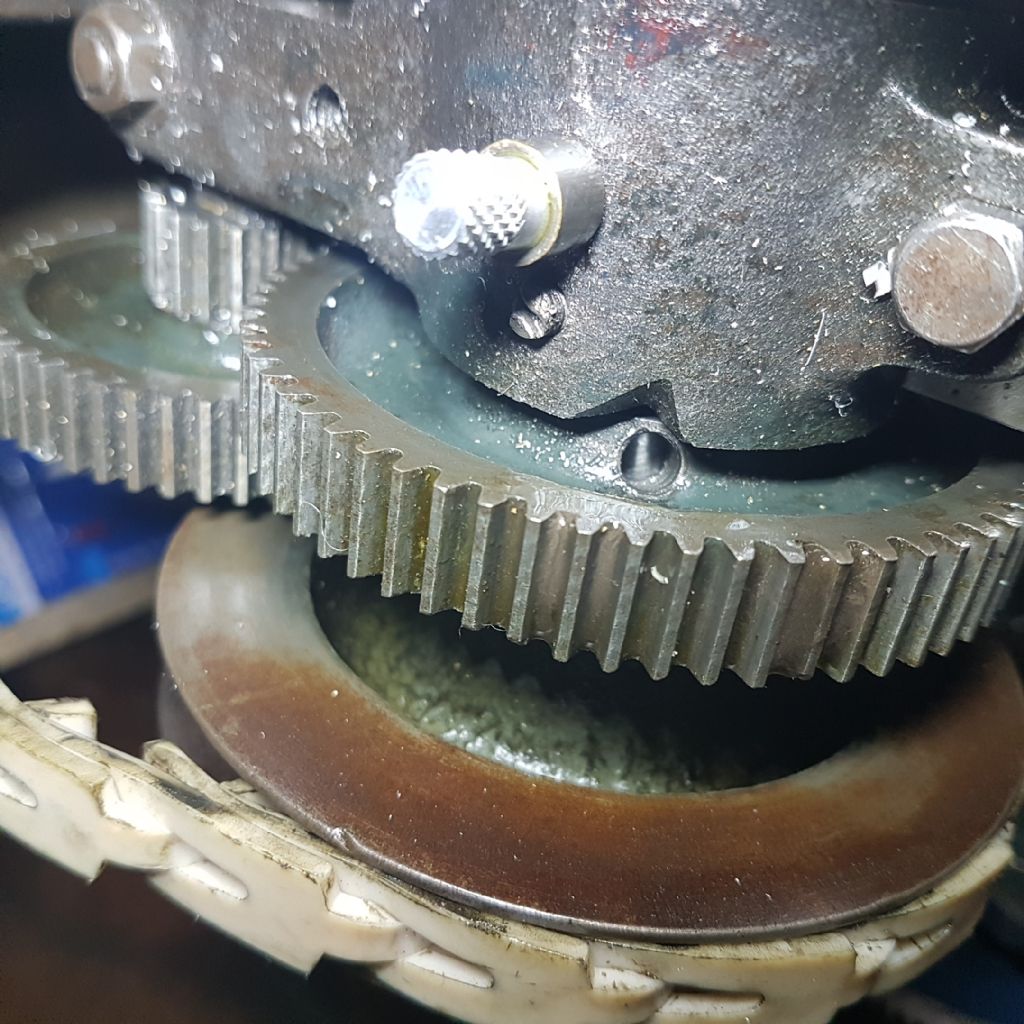

The Back Gears refer to the cluster gear pair [in the case of an ML 4 lathe for example, there are other variations on other lathes] that engage with the spindle bull wheel at the chuck end of the lathe so that low spindle speeds can be obtained.

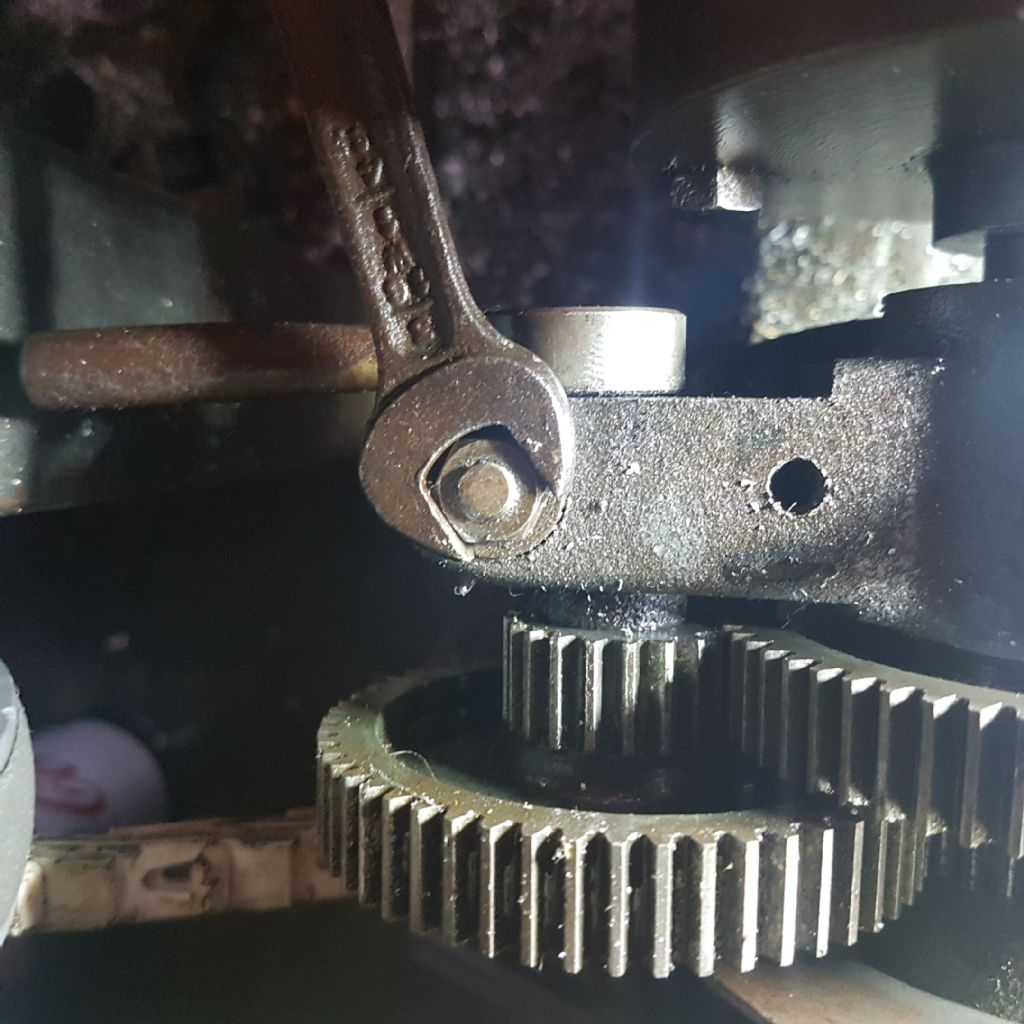

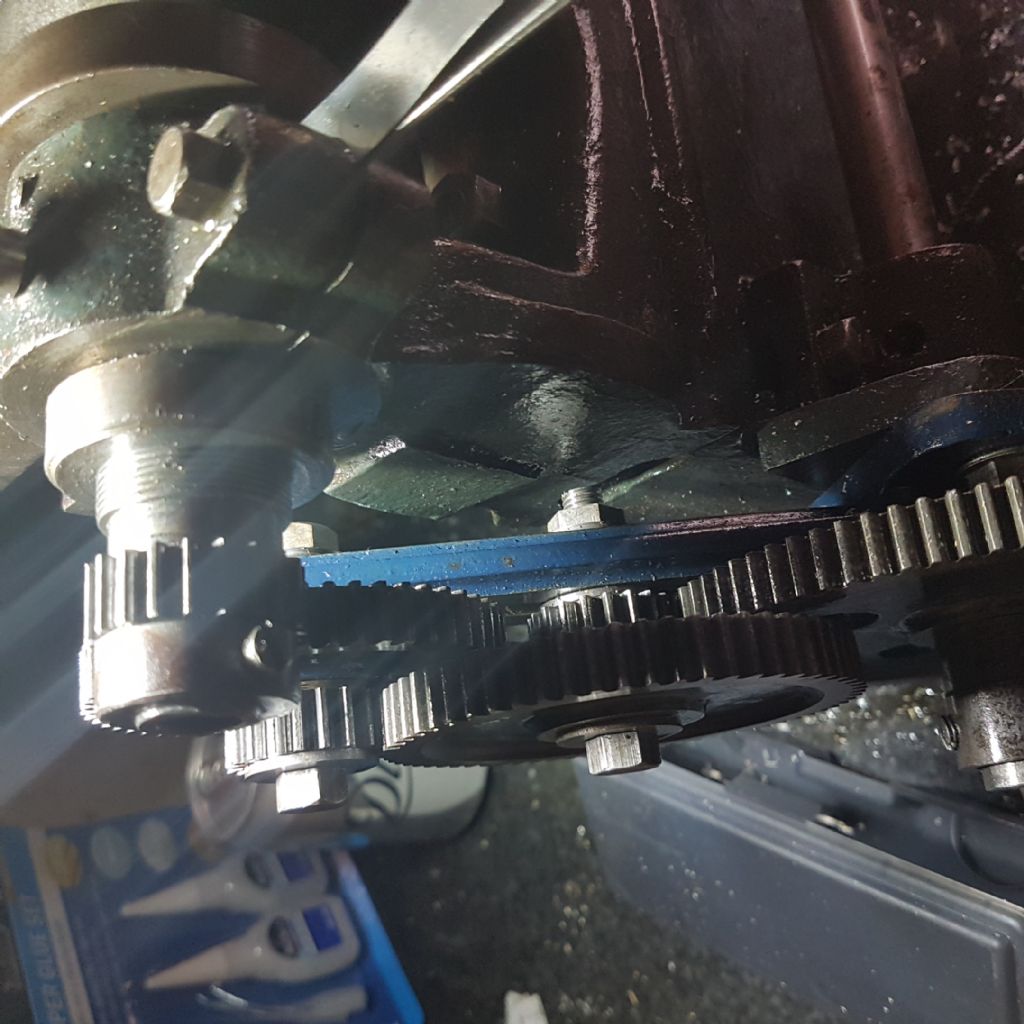

The gears at the remote end of the lathe that couple down to the leadscrew are invariably called the change gears for the good reason that they are changed to alter the rotational speed of the leadscrew with respect to the spindle and chuck holding the work

To address Martyn's two problems; first the back gear. The lever operating that is fitted on a short eccentric shaft so that the gear cluster can be swung into and out of engagement. From memory I think it fits through a split hole in the headstock which allows a nip bolt to adjust the degree of clamping to prevent the problem you describe. Strip it out and clean it up, there could be a paint dribble affecting the fit on the eccentric and spoiling the operation.

Clamping the tailstock quill is done by the short handled lever on the front end of the tailstock which I think squeezes a pair of shaped plugs together that fit over the outside of the tailstock quill. Wear on one or both of the tapered faces allows the plugs to bottom out on each other and the clamping effect is lost. Extract them, turn or file down the plain faces next to the tapers to restore the clearance and refit.

The gearing tables are well advanced and very comprehensive, they are equally applicable to non-gearbox ML7 lathes, I shall be releasing them soon as a pdf at £2.50 a copy on behalf of the Remap charity that does good work in making life easier for disabled people of all ages.

I shall post again on this thread with instructions on how to order the pdf.

Regards

Brian

Edited By Brian Wood on 14/04/2018 11:25:06

Jon Cameron.

Jon Cameron.