Posted by Thor on 23/09/2015 18:51:17:

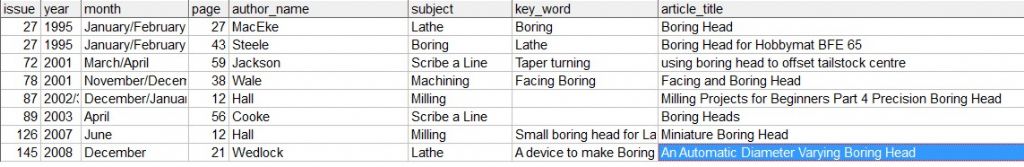

John, there are a few description of home-made boring heads that you can download, her's a couple:

***Link***

***Link***

Thor

Thanks Thor those may interest others. I have a perfectly adequate boring head that I posted a shot of earlier but facing with it now isn't so easy due to the see saw attachment it needs to face.

I'd make a couple of points about many of the ones that are about. One of the reasons mine is heavy, bit short of 4kg, is to provide some fly wheel effect. The main body is a lot heftier than it need be. It was from castings but the same could be done from square section steel rather than round. This then gives a nice long slide and there can be more tool positions than the usual small round ones. The very dear commercial heads tend to be a lot bigger. This is probably more important when the head is used for facing but always having a good length of contact in the dovetails must be good for rigidity. If I made a round one I would probably base the main body on 4in dia steel 2 to 3in thick.

I think mine was designed by Westbury hence the actual tool holder being bolted onto the slide. That way if I ever need it for something I hadn't thought of I can quickly make something to fit to it. He's also the sort of person that would think about flywheel effects for interrupted cuts and general smoothness. Some of the older designs are pretty clever really. Why use a plain bore in the universal dividing head for instance. It even makes sense if it's going be fitted with a collet chuck.

Mine fits on a myford spindle nose. Matches the miller and I have a 3 morse to myford adapter for my boxford.

Michael posted a link showing me how I can get it to face on my miller – a dore westbury. Silly me. It will be tight but I could mount the see saw on the quill using the ring that carries the quill travel stop. Fitting it to the lathe wont be so easy. For that the type with a ring that's moved to engage the feed would be easier. I think that the MEW one worked like that but my memory of the details is sketchy.

John

–

John Hinkley.

John Hinkley.

So no not that one.

So no not that one.