There is rarely only “one correct way”. With your example of turning a taper, in what way is turning it with a taper attachment inferior to turning it with an offset tailstock? Is it not true that either can produce a satisfatory result, and that each has advantages and disadvantages? Depending on the circumstances, one method may be preferred to another for purely local reasons, such as whether or not a taper turning attachment is available. If it is, it is likely to save time on setup. (and reset) But of course many amateurs do not happen to posess one, and it may not be worth obtaining one for a limited number of items. I happen to be a professional myself, but in telecommunications, another of our members is a surgeon, while yet another is a lawyer. So we at least know that there is nothing magical about being a professional. (Actually it carries a professional obligation to admit your ignorance where necessary)

Terry can be annoying at times, but you are not exactly winning yourself any friends with your own attitude. I don’t know how much experience you have with written rather than spoken communication, but it would seem to me that you have a bit to learn about how to avoid offending and annoying people. Since the whole point of making a post is presumably to communicate with people, it would seem counterproductive to switch off a large portion of the possible audience before they have read anything you might have to say. Some of what you will see here is advice from people who have used the technique they describe, some is not, but is for instance a suggestion of what they would try based on their own experience and equipment. You can usually tell which is which, especially if you have followed things for a bit. Most of us are willing to consider other approaches, we are here to learn. Indeed, there would be little point in reading the posts if there was not the hope of learning something.

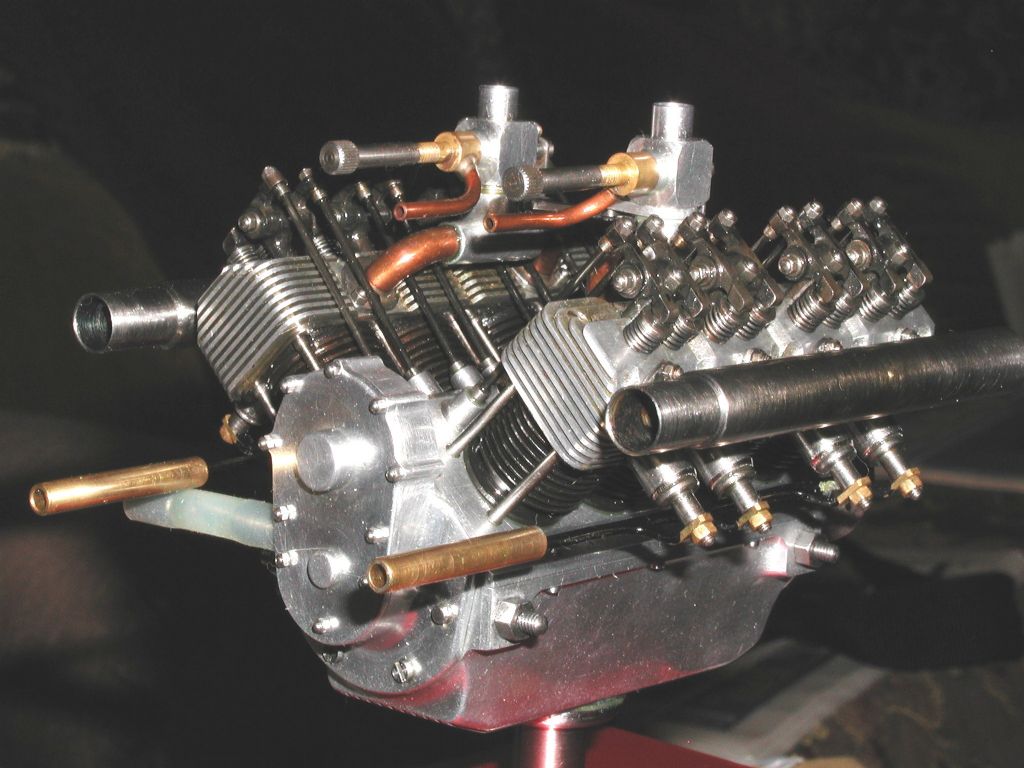

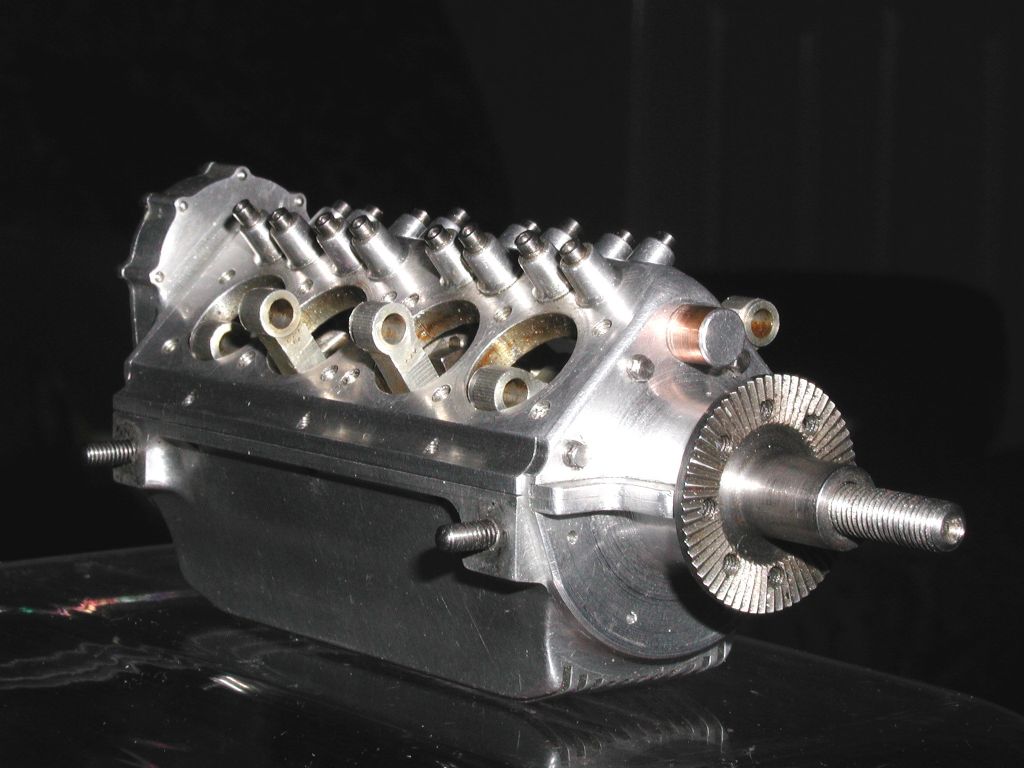

Finally “model engineering”, whatever that actually is, is not actually the same as industrial production engineering or even toolroom engineering, even if the particular part to be made might be extremely similar. In the production case, where large numbers of identical parts are likely to be wanted, it is a case of tooling up with the ideal equipment to do the job, or farming it out to someone who specialises in that sort of thing. In the toolroom case, it might be closer to the amateur situation, except that the machines available are likely to be of a wider variety and to a higher standard than the amateur can afford. Also the amateur undertakes a far wider range of work than is usual for any one worker in industry, he or she will do his own pattern making, in some cses the moulding and casting, then the machining and fitting, the boiler making, the painting, the woodworking…..und so weiter. In lieu of having the right equipment, the amateur will often pay in time, for instance by doing by handwork what industry would do on a specialised machine. Whether or not the standard reached is as high as might be reached under top professional conditions is immaterial, since the whole point is to have the pleasure of doing it oneself. And of course quite often the standard is such that the professionals can’t beleive the equipment it was done on.

David Clark 13.