I would just like to say a massive thanks to everyone that has contributed one way or another. I have taken every single bit of advise on board and i am delighted to say perseverance has paid off!!

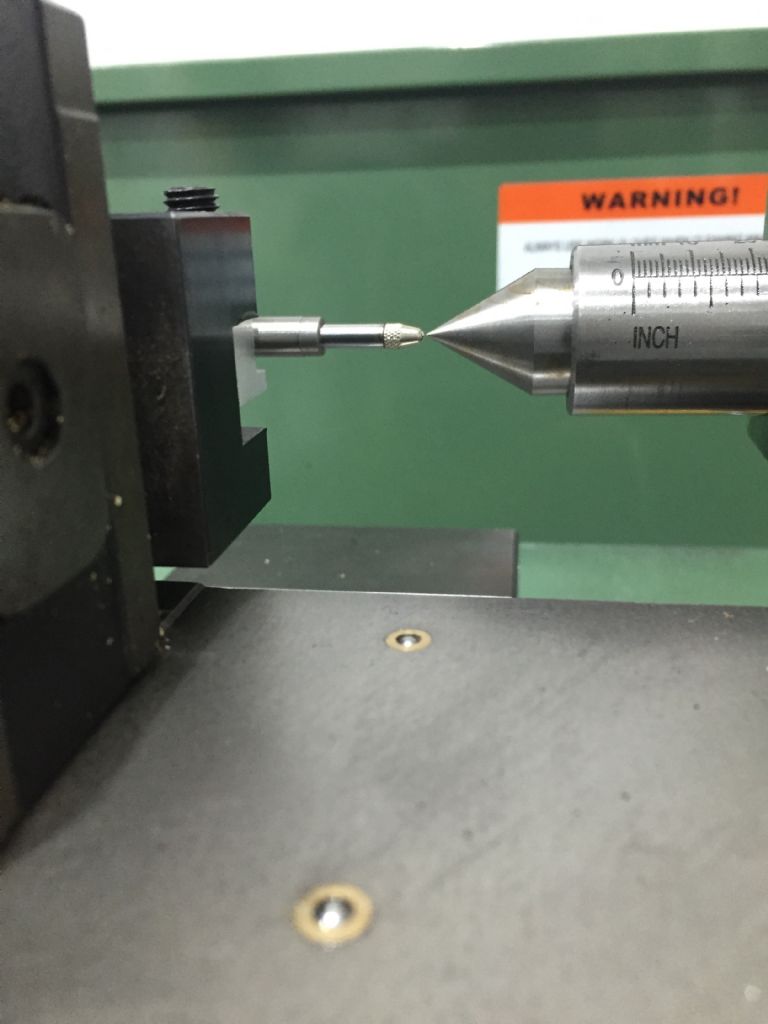

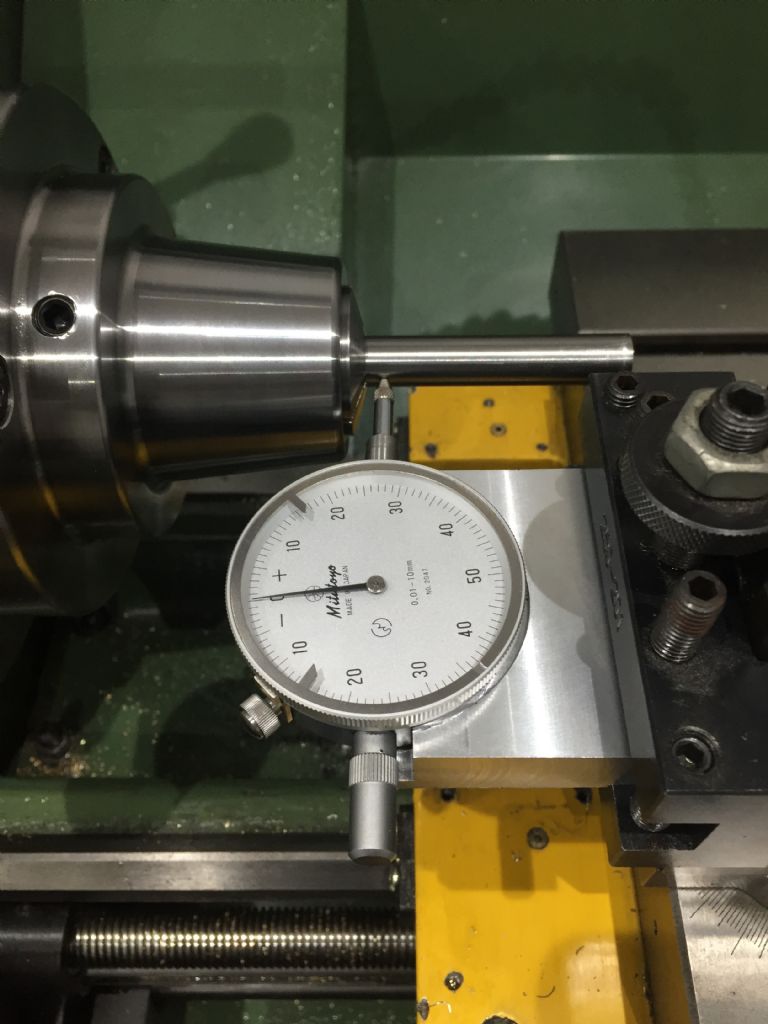

Checked the nose this afternoon in-between work on my Axminster DTI and it was still jumpy, about 0.01 out which is ok i guess but i wasn't convinced with my clock… So i paid a visit to Midland Metrology The reason i have put a link to this place is i was astonished by there friendliness, help and advise and the time they took with helping me. I asked them about a lever DTI preferably a secondhand branded one, they guy said that they didn't really have any lever type DTI's in secondhand at the moment then paused and took my to a draw full of clocks and said these all need looking at or have parts missing, see if anything is any good to you, I ended up finding a Mitutoyo 0.01 DTI that was only missing the lever… a quick look around and i found a brand new lever and spanner to assemble it! The best part is he said i could have it for a tenner! I then asked about pin gauges to check the collets, when i explained what i was doing and the trouble i was having he dug out a box of imperial pin gauges and said there are a few missing but what size are you after i had a quick look and said the 1/4 would do just fine (i know i was using 1/2" originally) but that was one of the gauges missing, he then took the 1/4" gauge and took it to there test room and check that it was running perfectly true and perfectly round. After he confirmed it he gave it to be and said there you go just bring it me back when your done! I was over whelmed by the level of service and trust they have so i thought i would let you all know if you are after any secondhand or new measuring equipment these guys are well worth a visit or phone call.

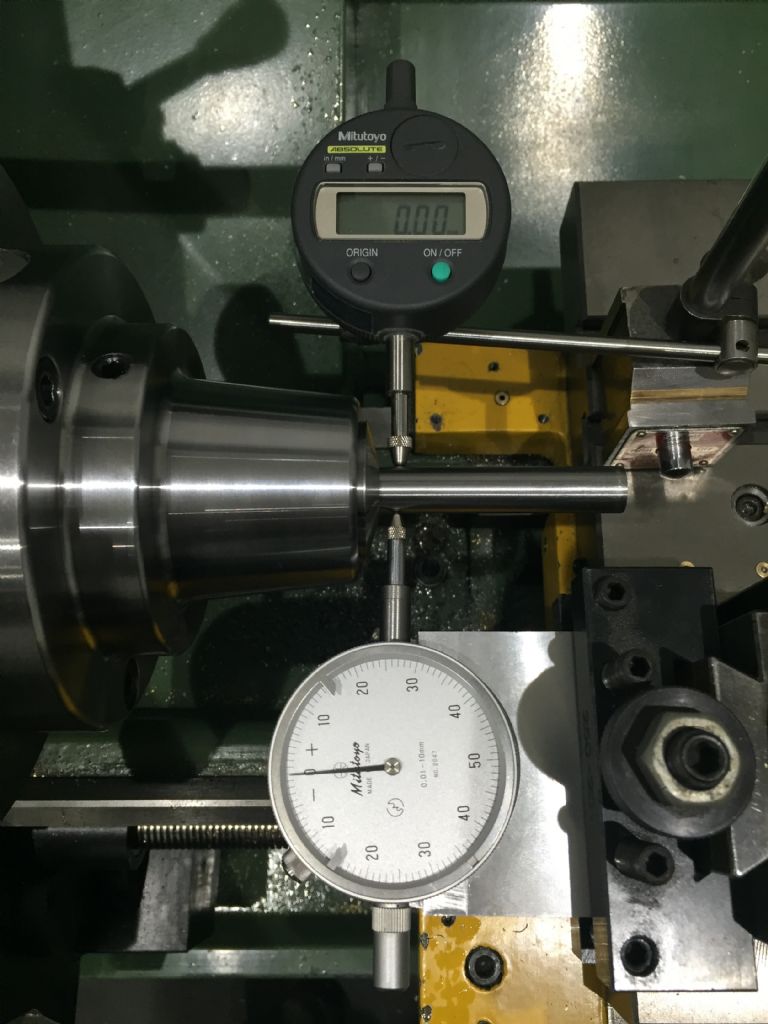

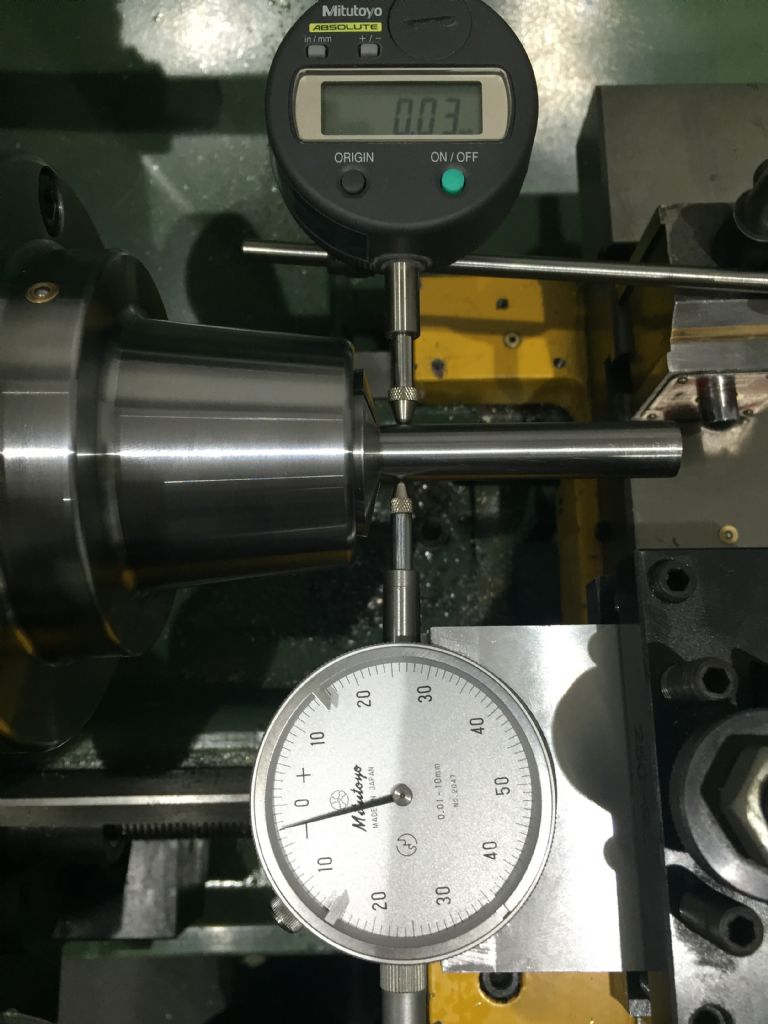

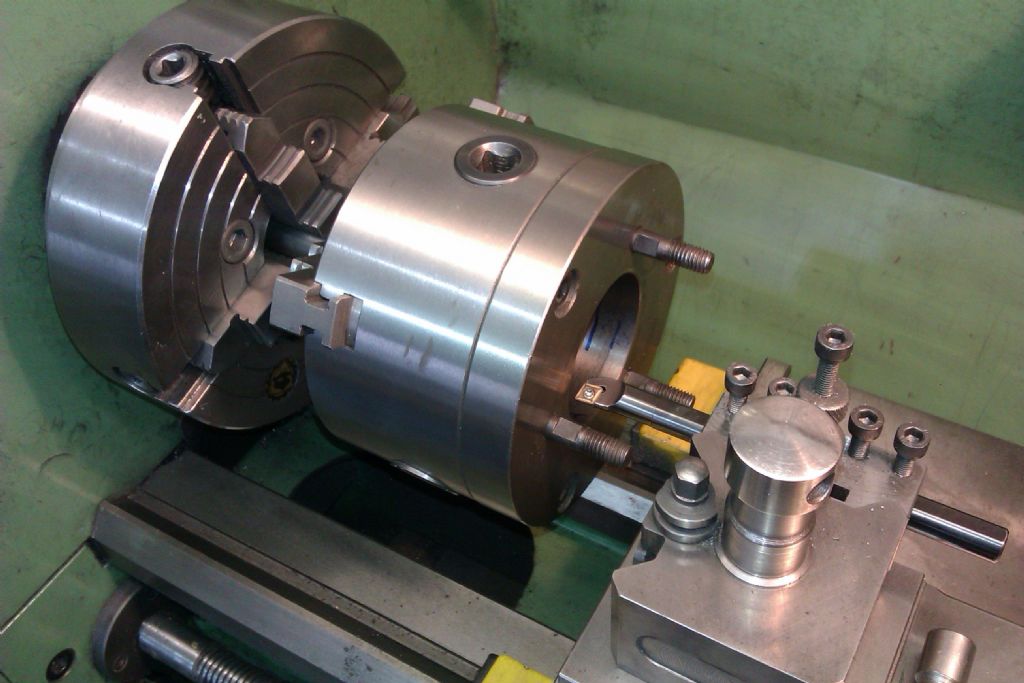

Any way back to the chuck… So new DTI set up and re checked the nose and hey presto no movement! I was over the moon, next was to check the 1/4" collet with my gauge pin and amazingly even that was dead on! My needle didn't appear to move at all, bang on 0 no matter how slow or fast i spun the chuck and it was repeatable! Short of getting a 0.005mm clock i am happy to say thats as true as it gets

I think the morel of that story is keep persevering and make sure you buy quality equipment, although its old or secondhand doesn't mean its not as good, infant far from it, my £10 DTI proved to solve the majority of my headaches. If i had the money i would buy a better quality chuck but it turns out that some of this Chinese stuff isn't that bad after all, just gota choose carefully i guess. I would also say the cheaper stuff requires a lot more time and patients than a more expensive brand. These are just my findings any way.

Thank you all for your help and advise

Steve

Chris Evans 6.