Many thanks for the pointers and advice – I think I understand what's going on now.

Firstly, confirmation that Aluminium is difficult helped. In addition to being sticky and with a low melting point, I hadn't realised that it might also be age hardened and/or stratified. Also there's a strong tendency for aluminium swarf to jam in the slot, for the metal to melt on to carbide, and – being relatively soft – to dig it when cutting conditions are poor. Lesson learned: take extra care with Aluminium.

I've taken a close look at my set-up and found a number of issues:

The insert I was using isn't blunt or chipped. However, it has collected a layer of aluminium on the tip. It's very firmly attached: I think welded. I can imagine this dramatically reducing the effectiveness of the edge. It might also explain why the tip flips between cutting and not cutting. Possibly after the layer of Aluminium has built up and stopped the insert cutting, the tip chatters and rubs. In doing so the heat and vibration may eventually be enough to dislodge the unwanted layer causing the insert to suddenly start cutting again. Any rubbing thereafter would put another layer of aluminium back on the edge causing the cycle to repeat. The original layer of aluminium on the tip was very likely caused by rubbing. Rubbing is caused by insufficient speed, feed-rate or lubrication, and by swarf catching under the edge. Possibly using the wrong insert for Aluminium. All operator errors.

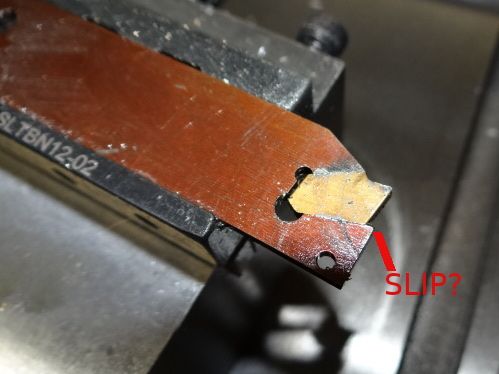

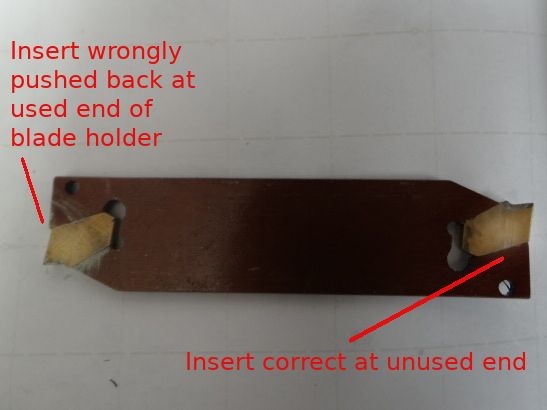

The next problem is that the insert is pushed too far back into the holder. I think this was due to a dig-in. Although the insert survived, the holder has stretched slightly. Compared with the unused end of the blade, the insert in the used end is distinctly looser.

The pushed back insert still works on small diameter rod, but there's a problem with the same tool with a large diameter. Note that in this photo using the insert has pushed it even further back, which also drops the edge away from the centre line.

Worse, when the tip is pushed back, the lower edge of the blade holder contacts the work first. There's enough clearance when parting small diameters for fouling not to happen, but it matters at 5". Lesson learned: keep an eye on this type of holder, especially if there's been a dig-in. The blade I'm using is inexpensive; brand-name equivalents are about 4 times as expensive. Possible the steel is better.

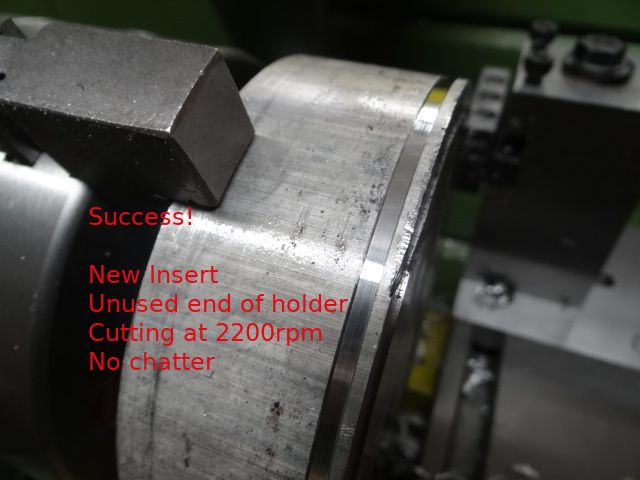

Conventional advice with chatter is to back off. This is what I did, reducing speed to 480rpm. Armed with your new advice I tried the same set-up with a new insert in the 'good' end of the blade. I also ran the lathe at the industry recommended speed for cutting Aluminium with carbide – 2200rpm at 5" diameter. This is moderately scary.

What a difference. Lathe whirred happily and chips came off in a shower. No sign of chatter and I cut the groove shown in a few seconds.

May I congratulate everyone on their answers. You chaps excel at this sort of question. I got loads of good advice, solid expertise, and valuable pointers I might never ever have thought of. Many thanks.

Dave

John Reese.