Hi Jeff,

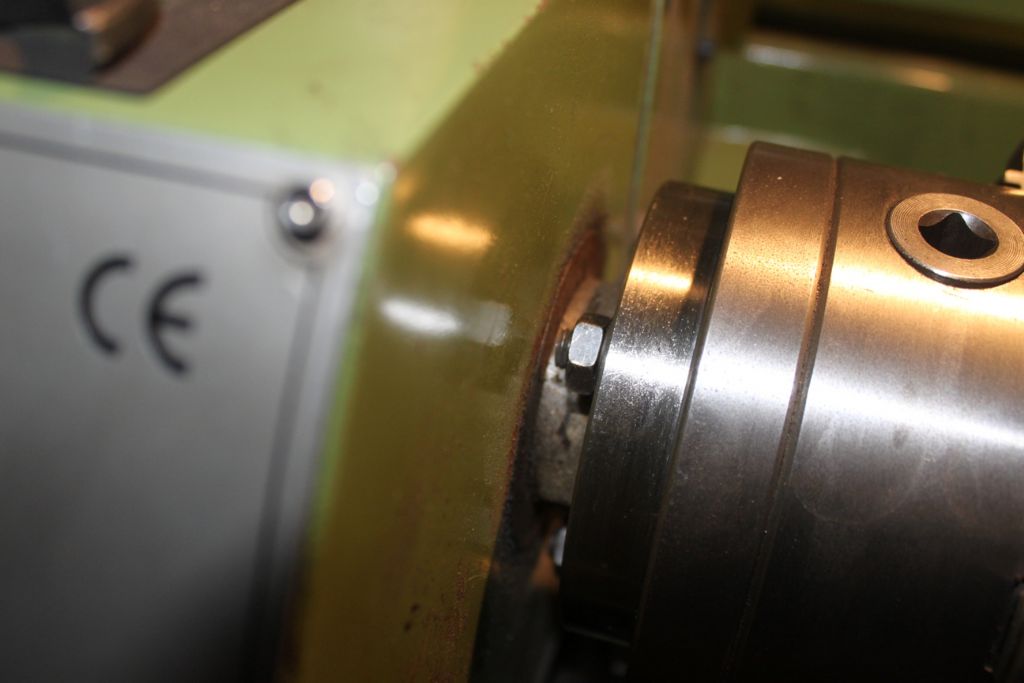

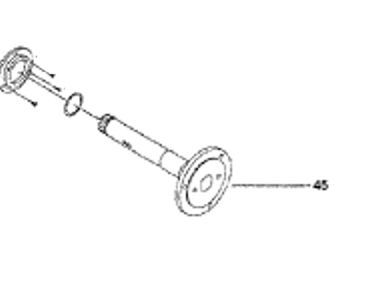

If this is the first time and you have removed the three chuck securing nuts from behind the mounting plate, it is probably stuck with the protective grease that was originally used to protect these components. I had the same problem and used a rubber mallet to knock the chuck off. You need to rotate the chuck a little after each blow. It will release suddenly so be prepared as Jens said by protecting the bed with ply, I have a specially shaped softwood cradle which protects the bed and is used to store the chuck, I'll take a picture later. You may also like use a large wad of cloth, both to cushion the possible landing and to prevent it rolling off the bed if the chuck releases unexpectedly. A rubber mallet will not damage the chuck.

Tips:

Switch OFF the power to your lathe, do NOT put your free hand under the chuck to catch it, you WILL cause yourself an injury, Also be sure to REMOVE any fabric before turning the lathe on again. Clean off the protective grease with white spirit and lubricate chuck locating spigot with a dry grease, I use PTFE spray – it doesn't attract swarf or grit – to prevent sticking in future.

Regards

Terry

P.S. I Forgot  , do not remove the nuts completely from the securing studs, screw them to the end of the stud then use the mallet. This will prevent the chuck dropping unexpectedly when it releases.

, do not remove the nuts completely from the securing studs, screw them to the end of the stud then use the mallet. This will prevent the chuck dropping unexpectedly when it releases.

T

Edited By Terryd on 07/10/2012 07:56:20

Terryd.