Yesterday actually; Was sorting out garage / workshop & going through measurement tooling & for some reason looked at my Wixey digi angle gauge & thought I don't have angle gauges per se. I remember seeing some on the forum some time ago, or was it YouTube ?, any how decided to have a go at making some, but using trigonometry to get the angle as I have seen from various other posters & videos.

Had a look at what stock I had & found some 5 mm aluminium plate, that will do nicely methinks so started out with the simplest – 45* & if it works out will make myself a basic set of 30* – 25* – 15*. Started off marking out from two square edges & located two centre points for drilling & reaming for supporting the hypotenuse edge in the mill. I used two 3mm milling cutter shanks as precision fit into 2 x 6 mm reamed I know that as 45* is the simplest to mark out so using the 2" square I marked out would simply mean joining two corners ( side a & side b ) with a diagonal would give the required 45*, but often the case that eyesight, slight movement of rule etc would not hit the exact corners so wanted to see how close trig' would get it. I also decided to include a step to allow for location repeatability when machining of more than one item…

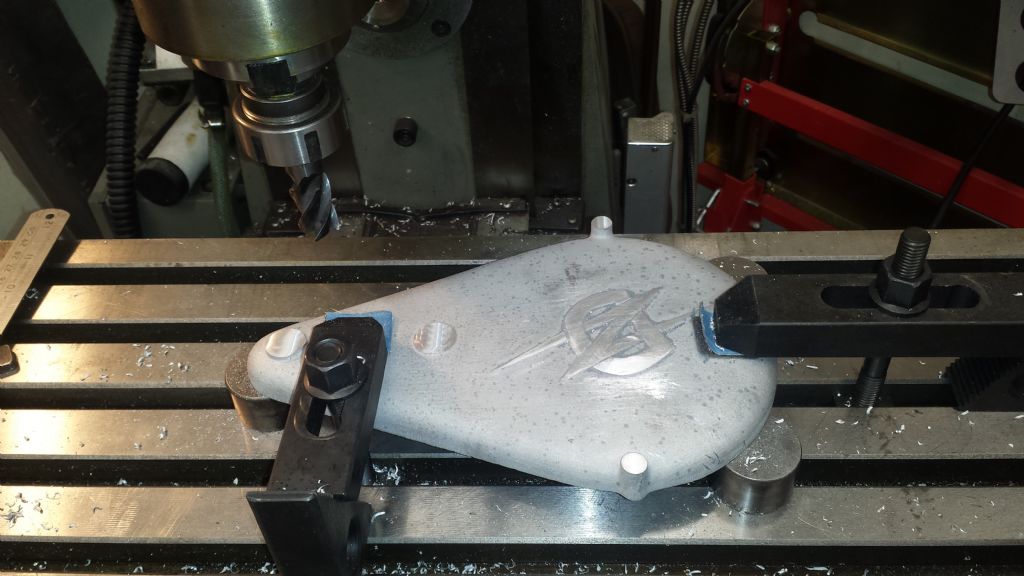

Finished gauge showing stepped edge…

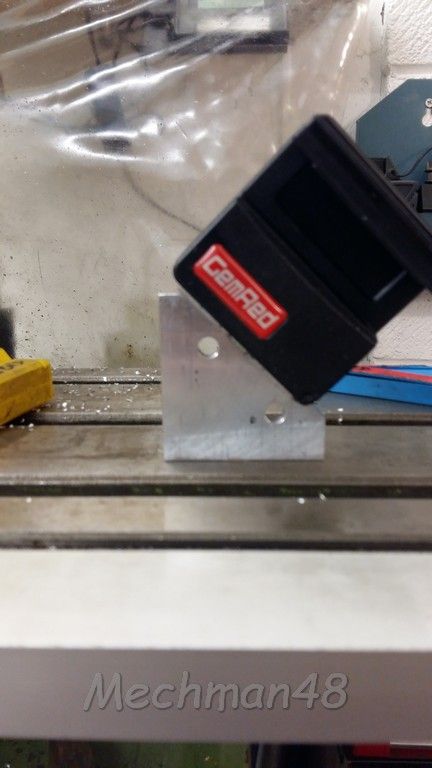

Using the digi gauge sat in the stepped hypotenuse as a check, already zeroed from mill table…

The digi gauge showing discrepancy of 1 minute… that could be due to a slight burr on the bottom of the digi gauge ? or maybe the vice is not 100% flat on the table etc… I had to machine the bottom of the vice some time ago as it wasn't sitting flat or square to the table, could be other factors too…

Can't complain at the 1st attempt though. Comments / tips welcomed…

George.

Steviegtr.

Steviegtr.