Thanks for all the ideas chaps – much appreciated, but I'm still not getting my head around this concept!

IAN Perfectly valid suggestion!

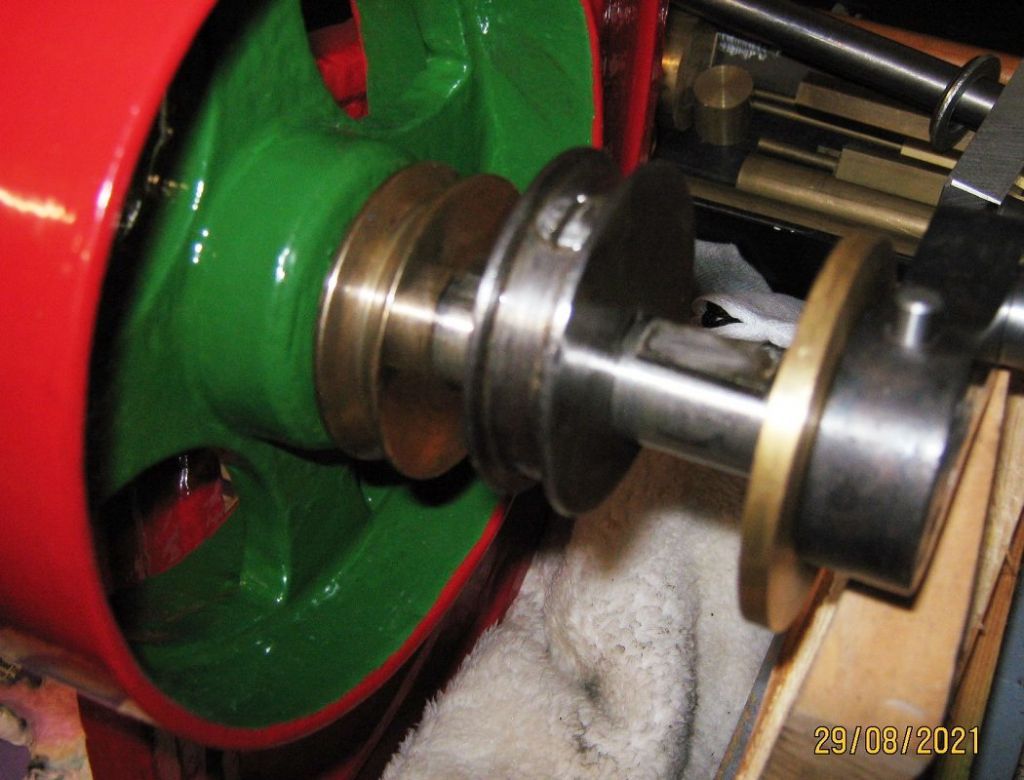

JASONB There isn't any radial adjustment as the key and the keyway are close tolerence and the flat on the shaft of course is static, so even with the screw loose you cannot adjust the position radially.

PAUL The key themselves are a flat wedge ( like a cheese slice ) close fitting in similarfly tapered ways in the eccentric they have a slope of about 1 in 12 to my reckoning.

HOWARD They are very close fitting, but when in situ, even just pushed in finger tight, there is no gap at the top at all, so would not appear to be able to lift as you suggest.

ROGER so why do they use a wedged key? Surley a flat one that the screw then locked in position would be adequate? In some ways better as once the ' wedge ' becomes even the tiniest bit loose they key displaces and becomes ineffective.

CLIVE Following all the thoughts here, I'm starting to wonder, as per your comments, if these keys should NOT be ' hammered ' in tight, but just ' firmly inserted ' instead and then the screw tightened. Whilst not giving any radial freedom to adjust, you would find it easier to position on the shaft to accurately line it up with the rods activating the slide valves on the cylinders?

When I first received the engine it was in a dire state and everything was rusty, siezed solid or corroded so evary part had to be hammered off, so I have no idea what the original fit might have been like.

Any further thoughts or observations will be much appreciated. Rather cool, grey Bank Holiday weather here in the Midlands today, so don't think I will be venturing far or wide , so probably a workshop day anyway!

All the best. Mike

Mike Hurley.