From time to time I delve into the black art of making injectors, I've been quite successful in making the 24oz size but struggled with the smaller sizes mainly due to the difficulty with drilling the small holes, my lathe just hasn't got the speed. What I need is a high speed drilling attachment, I've been pondering this problem for some time had a couple of ideas that I've rejected:- finally I came up with this:-

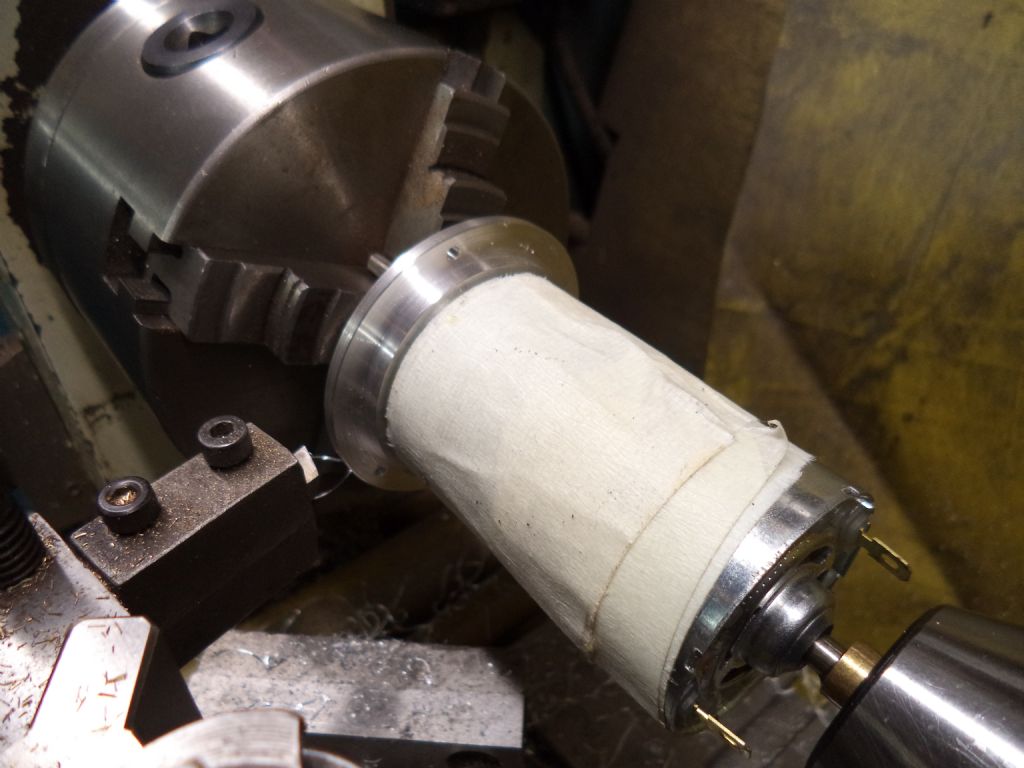

What the hells that I can hear you saying well it started life as this.

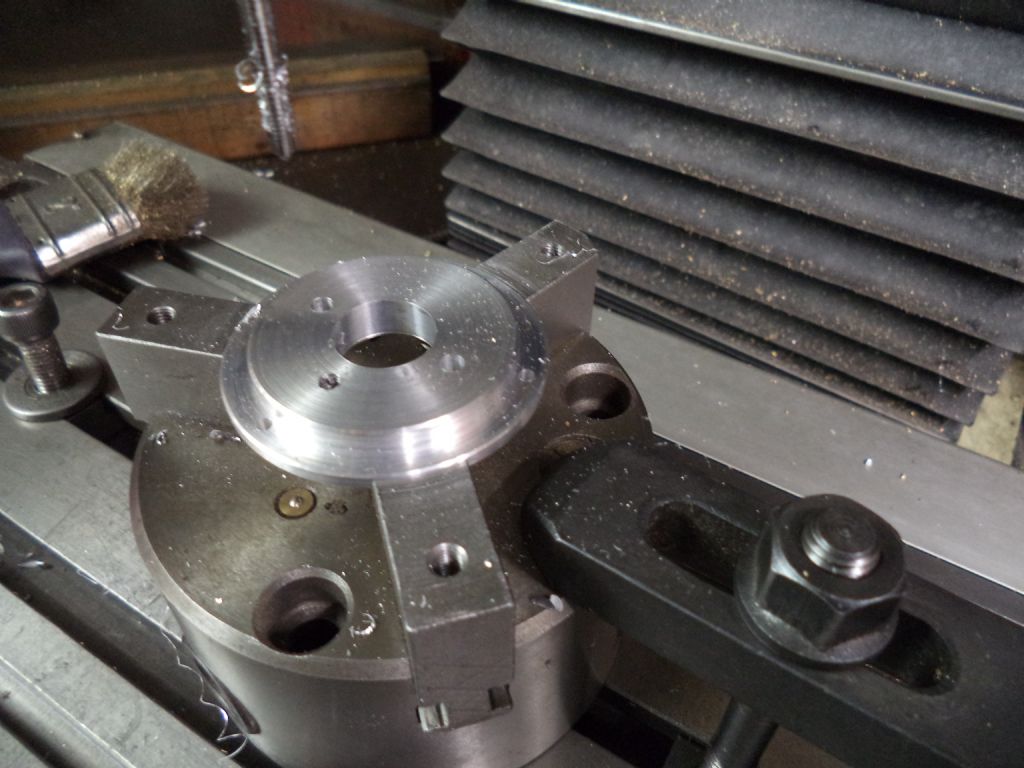

A 24V high speed motor with chuck that I found on the internet (5mm output shaft) a M3 morse taper threaded 1/2" UNF and a 2 1/4" dia chunk of ally.

Cut a slice of ally off and machine up the end cap,

Now its important that everything lines up with the centre of the lathe. The motor is screwed to the end cap, so the end cap must run true with the motor shaft.

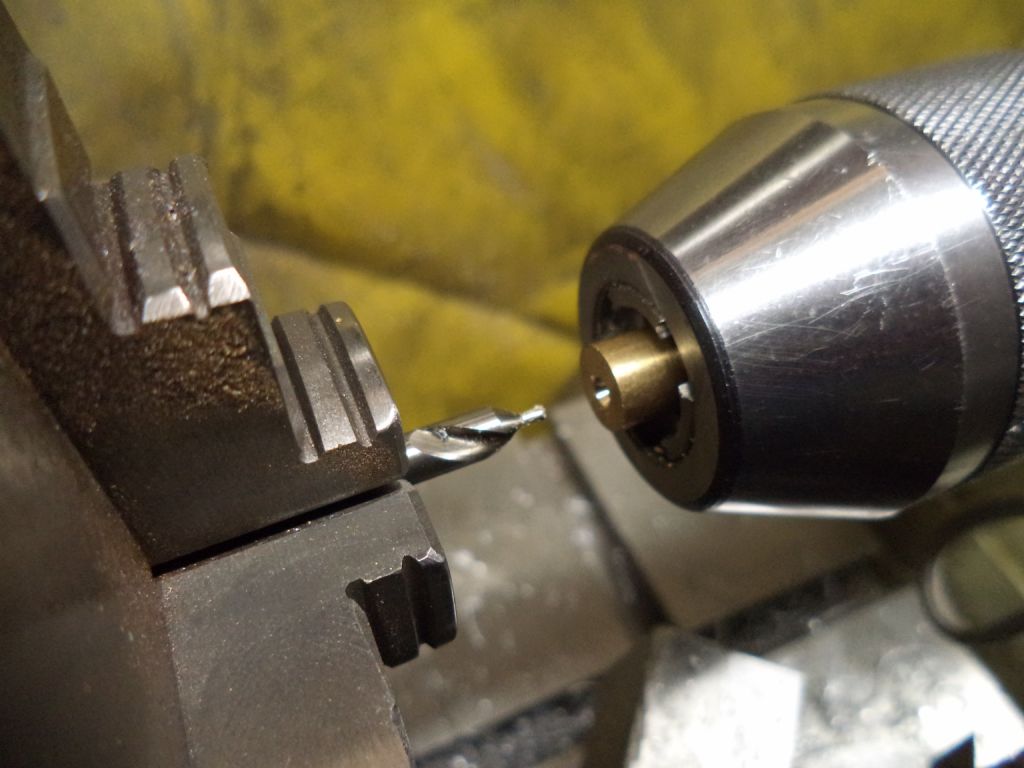

Make a temporary female centre.

Grip one end of the shaft in a chuck that you know runs true and suport the other end with the feamle centre and skim up the register dia and face of the end cap.

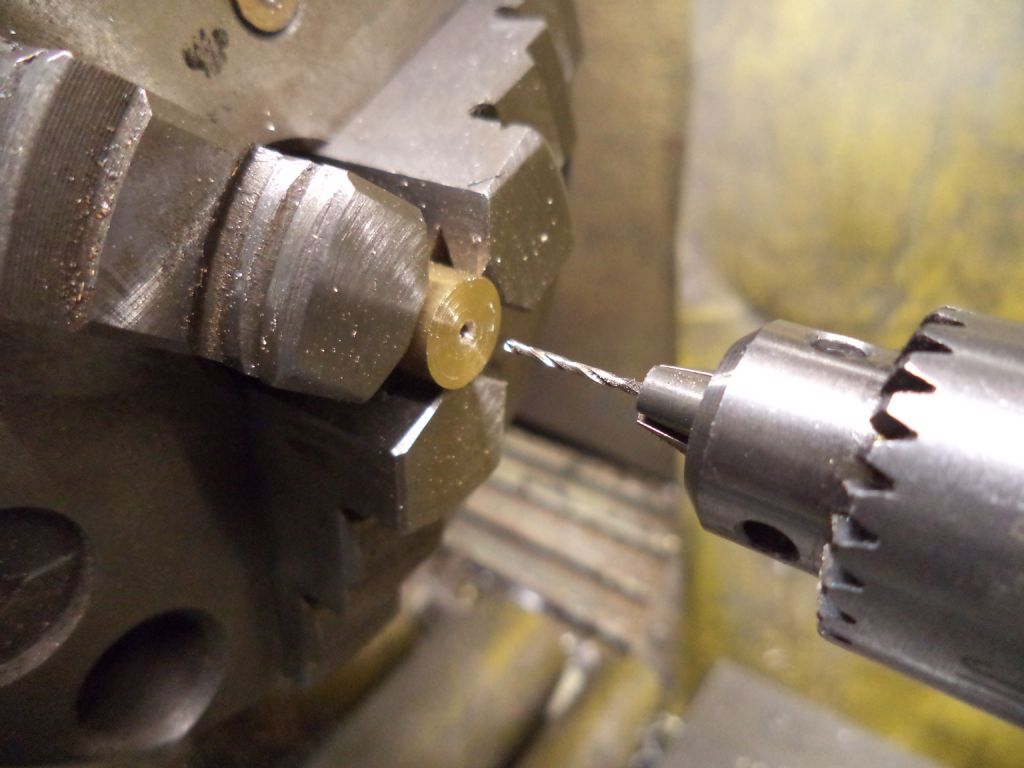

Clock the body up true and drill bore and tap to take the M3 morse taper abour.

Don't fix it in permanent yet

Flip it round clock it up again and rough out the bore.

Drill a few holes for cooling and wiring.

Now fix it to the Morse arbour, my lathe is M3 in the head stock so mount the assy in the head stock, and face and finish the bore to give a nice fit to the cap.

Check that everything lines up.

Proof of the pudding.

It took me just over two days to make it it seems to work OK I'll post a video over the weekend of it working

Stew

Edited By Stewart Hart on 29/01/2020 15:22:27

Stewart Hart.