The article is in ME 26 Oct 2018 on

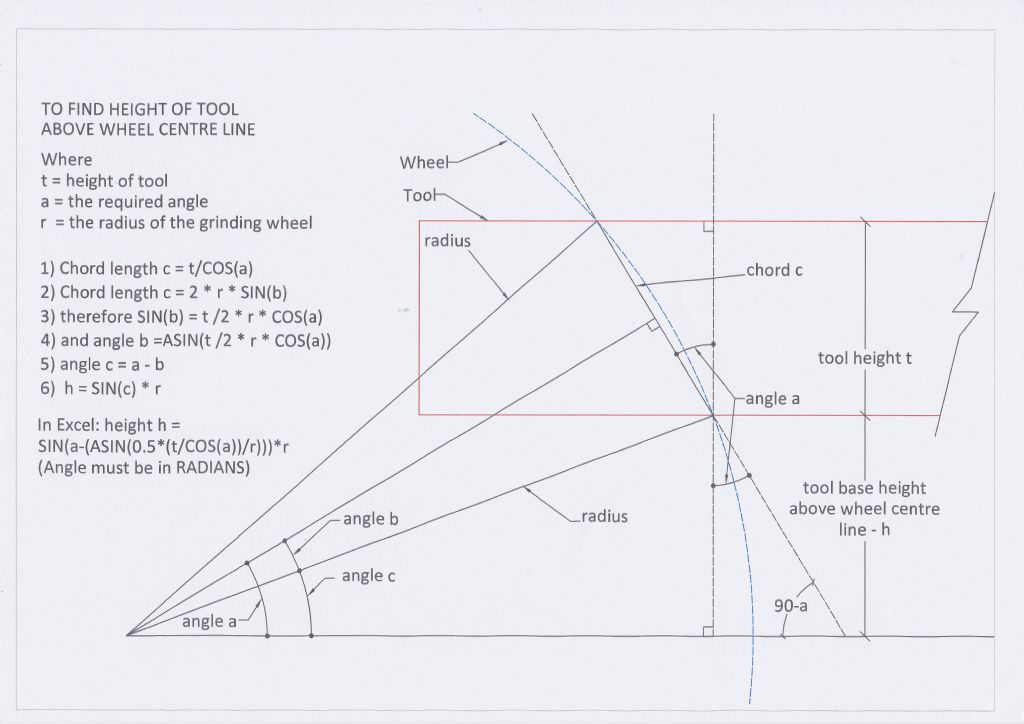

If you usually use 3/8 tools you only need one simple sliver of 1/8 steel to pack up your occasional 1/4 bit. In the previous article he had explained that for different angles he was using complete sub-bases but it might be simpler to draw yourself up a table of angle / tool thickness / packing.

Oddly enough after a club member demonstrated the concept I had written up in the October EDMES newsletter a table based on wheel diameter and angle for the top of the tool figuring our members would have to work out the offset depending on the tool thickness.

It isn't yet on our website (3 month lag so you have to join the club) so here is the relevant extract. I used figures based on using 1/16 in sheet as packing but it might be more helpful to find what sheet you have, perhaps it's SWG and recalculate the table for that. If you don't understand come along to the EDMES club meeting this Friday and I'll explain in person. (recruitment mode  )

)

The table below gives a few numbers for 6 in and 10 in wheels. Note the row labelled top is the top of the tool so the height of packing is that minus your tool thickness. A few shims gives you all the control you need.

| |

16th

|

4

|

5

|

6

|

7

|

8

|

10

|

12

|

14

|

| |

top, in

|

0.25

|

0.3125

|

0.375

|

0.4375

|

0.5

|

0.625

|

0.75

|

0.85

|

|

6 inch

|

degrees

|

4.8

|

5.9

|

7.1

|

8.3

|

9.5

|

11.8

|

14.0

|

15.8

|

|

8 inch

|

degrees

|

3.6

|

4.5

|

5.4

|

6.2

|

7.1

|

8.9

|

10.6

|

12.0

|

Don’t try to get a specific angle. Just use a nice round figure of packing, preferably a single piece. The aim is to get it to be easily repeatable, so after the first grinding a touch up almost instantly gets the edge back. If on the first grind you add a thin shim and remove it the touch ups are only grinding part of the face so are even quicker.

A possible downside of this is that the ground surface is curved, hollow ground, so slightly weaker but easier to touch up.

The reason for listing the settings for 8 in is that Screwfi

Chris Taylor 3.

)

)