Blimey! I didn't expect it to get this much attention. So….

Murray – No, I don't have any 3D drawings. It's about as much as I can do to produce the 2D ones. But if you're offering . . .

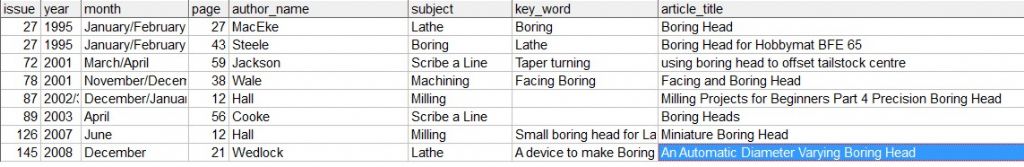

Michael – I looked at the thread in my off-the-shelf Asian boring head and that was mighty small, probably in the region of 0.5mm pitch. That's why I've gone for 0.75mm, as I'm anticipating the generated forces to be higher on mine.

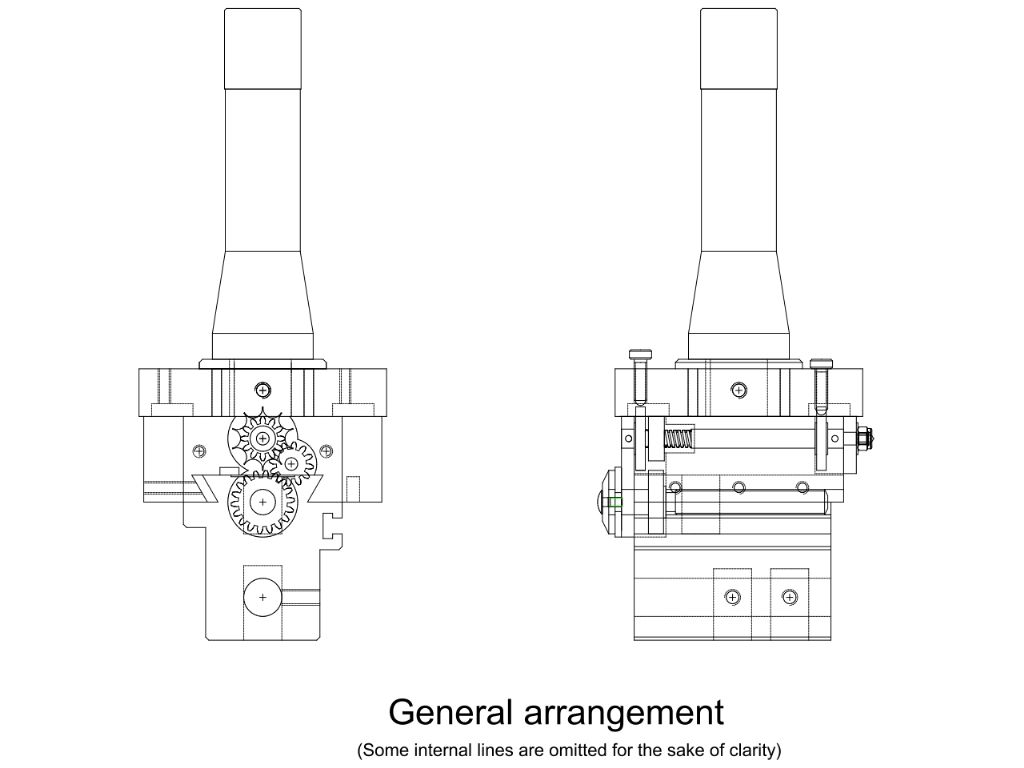

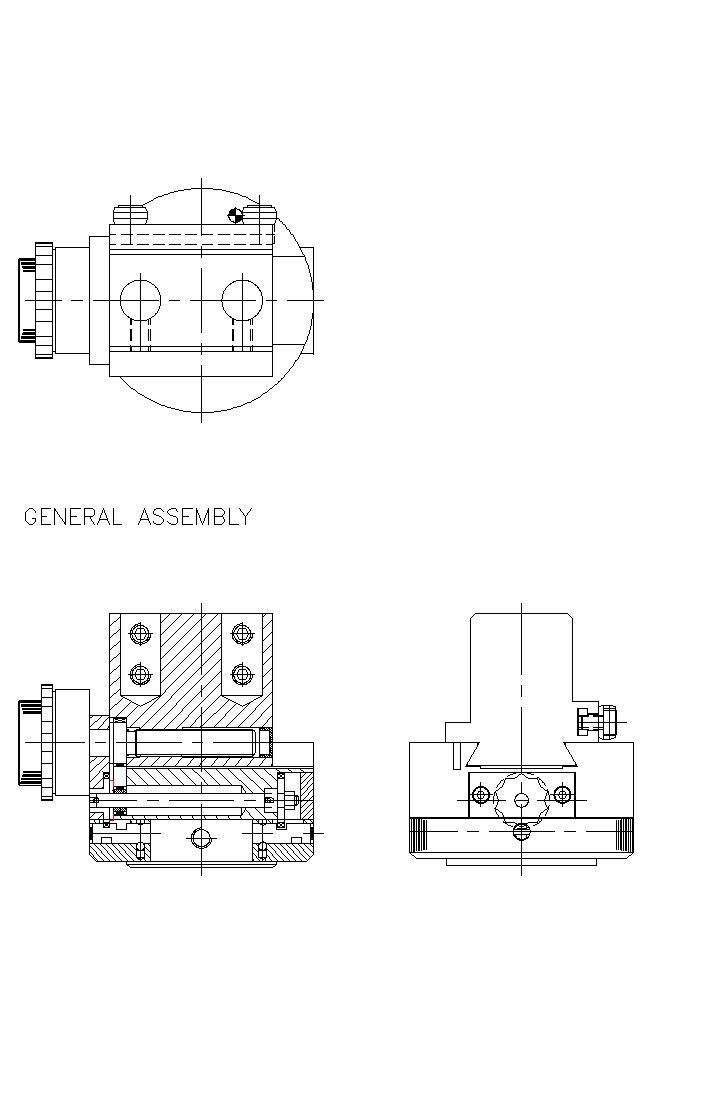

As I tried to explain in the post above, the feed screw is 0.75mm pitch – I happened to have one – and the feed wheel has 10 cut-outs, so one turn of the feed screw turns the slide screw 2/3rds of a turn – 0.50mm, thanks to the 12:12:18 gearing. Thus, one feed "click" advances the boring bar by 0.05mm. By having the drive pins arranged in two diametrically opposed pairs, differing PCDs and engaging with the feed wheels at the same differing PCDs, drive can be neutral, selected for an advance of 0.05mm or 0.1mm. There is, therefore, no need for the expense of a left-hand thread. There is provision for holding the feed ring by hand or using a screw-in bar to prevent rotation.

I'm on goodness only knows what version of the drawings – I've lost count – but I think I've found most of the errors and am about to freeze the design. Work has started on the slide and I expect to post some photos in an album in the next couple of days.

Other changes to Graham Meek's admirable design were prompted by the fact that I wanted a bigger one – who doesn't – and what I have available in the way of tooling and materials, etc. For example, I happen to have suitable MOD1 involute gear cutters obtained for a previous project, so I am using them instead of having to make and use a single-point form tool.

I must acknowledge the help I have received from John Stevenson and the encouragement he has given me in addition to a suggestion for further development. That'll be for another day. My brain hurts too much to start on that.

Regards to all,

John

John Hinkley.

John Hinkley.

Probably needing to lock it in position when not facing too but things can be spring loaded.

Probably needing to lock it in position when not facing too but things can be spring loaded.