I thought I'd resurrect this thread as I seem to be having the same problem that peak4 has had.

Many years ago I bought one of these made by Picador:

It was left unused until I read Harold Hall's book on tool and cutter sharpening and after one or two modifications I managed to get some reasonable results.

Recently I bought a kit of parts, from a well known auction site, for a Potts drill grinding jig. I bought it because it would be an interesting project to build and also Tubal Cain in his book on drills taps and dies said it produces drill points "very near to perfection".

Some of the parts were already machined and as far as I can tell are in accordance with the drawing supplied (from Woking Precision Models).

The jig is now sufficiently complete to be able to give it a try, however the result is disappointing.

The drill on the left is an untouched 3/8 inch drill as supplied by Presto, the centre one is a 23/64 inch drill (Dormer) that has been sharpened on the modified Picador jig and the one on the right is a badly worn 10mm drill of unknown parentage that I'm trying to sharpen using the Potts. On this the relief angle is now much steeper than the first two and looking directly at the point the chisel angle is wrong also. This seems to indicate to me that the drill point is too close to the axis of the jig pivot, giving too small a radius on the ground surface of the drill. This can be confirmed by putting a straight edge on all three drill points and comparing the curvature.

When using the Picador the minimum distance of the drill point to the pivot axis is about one inch, any less and you end up grinding the tip of the jig off. On the Potts it is much less than this:

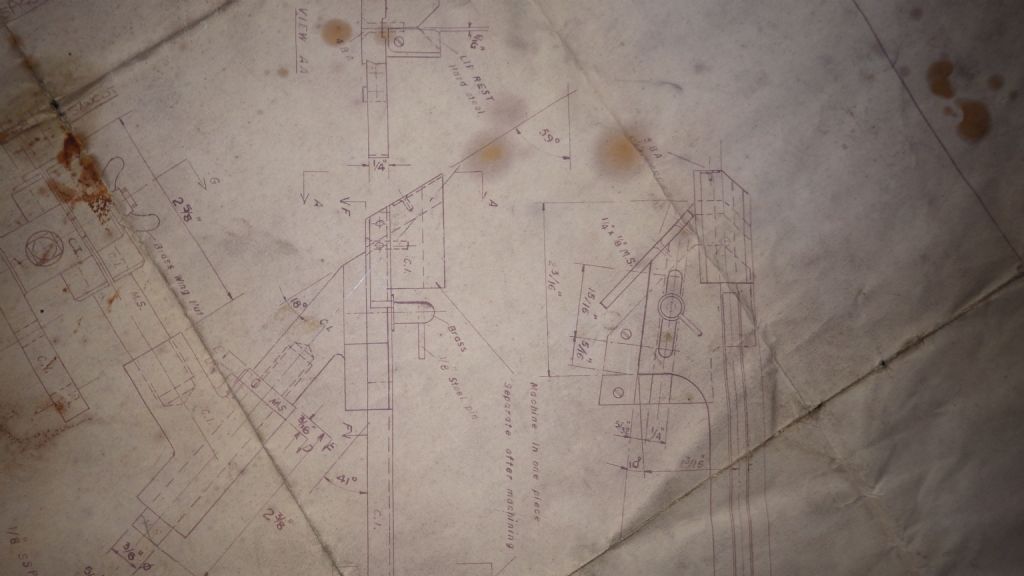

This is part of the drawing as supplied by Woking Precision Models. The scale is full size and appears to show the jig set up to grind a 1/4 inch drill. It's not too clear in the side view, but the pivot axis is only just (by about 1/4inch) behind the front of the jig which is where the drill tip should be.

Peak4, did you manage to sort your problems? I have the set up instructions if you're still looking for them. Can someone who has one of these tell me where I'm going wrong?

John

ASF.