Just wondering about the symptoms: motor starts, runs for 10 seconds then stops. Maybe noisy. Lathe moved recently.

Hard to tell but I think it's a single phase motor, exact type unknown – is a picture from the back possible (with a mirror)? It might show the motor plate (what does it say), start and run capacitors (which conk out), or a detached wire.

May not be a coincidence the lathe has failed after being moved. A terminal loosened by years of vibration, followed by the power cable flopping about enough during transit to detach one or more wires.

Single-phase motors fail for various reasons. As there are at least 5 different configurations, it helps enormously to identify the exact type. They all have a start and run winding, some way of shifting their relative phase (typically a capacitor or two), and maybe a mechanism (usually a centrifugal switch) for disconnecting the run winding once the motor has started. Some motors also contain a thermal cut-out.

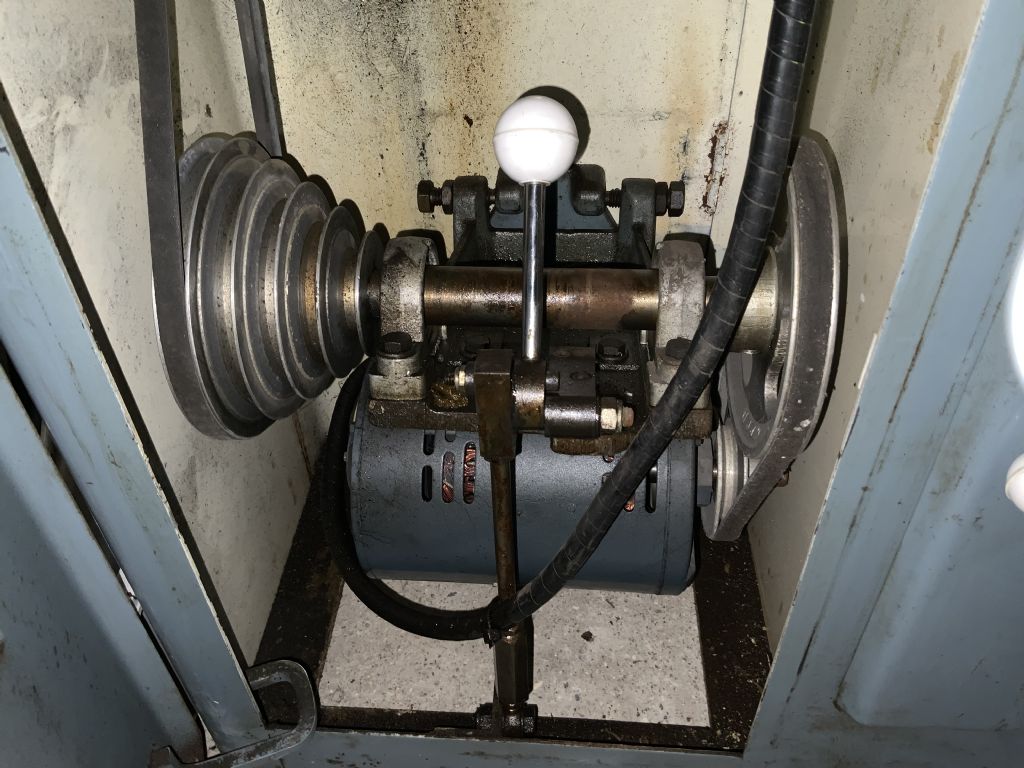

Noting the power feed dangles inside the pulley cabinet I'd look first for a cable damage due to rubbing and then check both ends at the terminals for solid connections and continuity (multi-meter test).

I can't think of a fault that would cause the motor to start and then cut out. AsI don't have lots of practical experience with single-phase motors, perhaps an expert knows? It suggests power gets to both windings correctly, then something fails. Maybe the centrifugal switch or the thermal cut-out is tripping prematurely. If it's type with both start and run capacitors, then maybe the Run capacitor is faulty. Works well enough to start the motor, but can't supply enough current when the run winding is disconnected by the switch.

Dunno!

Dave

Howard Lewis.