Opps, No worries Neil. I do forget that school children don't know swear words  Thanks again for the help the other day. It is appreciated ! FYI I am happy to conform to the sites policy's regardless as I have found the chaps and yourself very knowledgeable and helpful and would not wish to distress or shock anyone especially the latest generation of snowflake. I hear that the term snowman in no longer acceptable either ! Kids are taught that you need to refer to snow sculptures as snow people. Really REALLY. I fully realize and accept the need for a Code of Conduct. Most workplaces operate under some such guidelines at work. However most of the staff take the preverbial out of the C.o.C as well

Thanks again for the help the other day. It is appreciated ! FYI I am happy to conform to the sites policy's regardless as I have found the chaps and yourself very knowledgeable and helpful and would not wish to distress or shock anyone especially the latest generation of snowflake. I hear that the term snowman in no longer acceptable either ! Kids are taught that you need to refer to snow sculptures as snow people. Really REALLY. I fully realize and accept the need for a Code of Conduct. Most workplaces operate under some such guidelines at work. However most of the staff take the preverbial out of the C.o.C as well  I've run into some issues online before with swearing or some such and would be grateful for help in avoiding further issues ! So …

I've run into some issues online before with swearing or some such and would be grateful for help in avoiding further issues ! So …

While were on the subject, without sarcasm, trolling or any ill intent, where do we draw the line on what is classed as harassment or bullying. What is offensive exactly and when is PC actually oppression. Do we BAN HUMOUR ?I've seen a few distasteful you tube videos of feminists and SJW's (social justice warriors) but I've also seen many celebs and spokepersons speak out against them. Even Stephen Fry, a comedian I have a lot of respect for while i don't necessarily agree with all of his politics as he was a bit too far to the left is now suggesting the PC culture is getting foolish. His college, whats his face, black adder, is also now also standing up and rejecting the PC culture. Is that racist these days i wonder because it uses the word Black. I would say bring back Benny Hill, Rising Damp , Steptoe and Son and lest we forget Alf Garnet but to be honest I'm too tired and have better things to do with my time than argue online with SJW's or listen to Trolls try to provoke me or PC hypocrites tell me what to think. I will think what I want and i will say what I want but I won't do it here as this is not the place for that !

I accept i made an error in trying to inject some humour where i should have stuck to the subject and only the subject without letting personal beliefs,politics and feelings cloud the subject. But come on seriously !

Meanwhile i shall retreat to my mind and fill it with thoughts of countershafts.

>< Unless thinking of shafts is also inappropriate. The badgers will likely ok that off-course.

As is there right off-course.

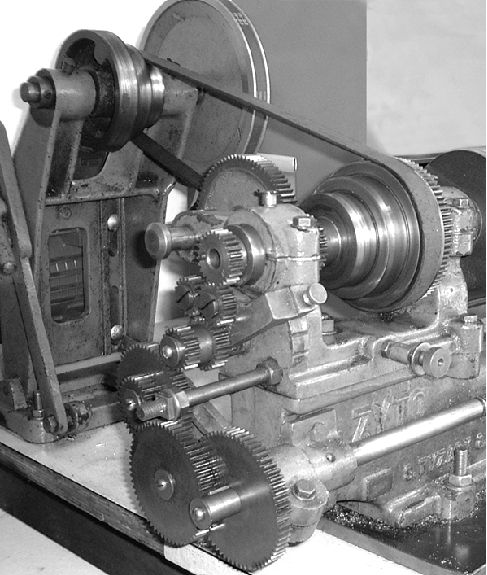

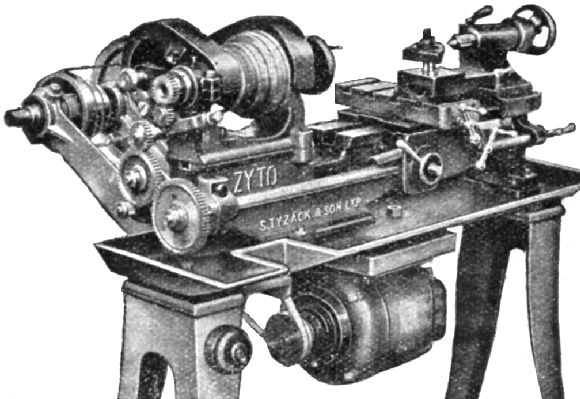

However more important issues remain. That of defending the honour of the proud and distinguished Mr S Tyzack and lest we forget his son. They produced a truly fine little lathe, much improved upon on earlier lathes and sadly left to languish too many years without major improvements. Now becoming a rare breed.Much like snowmen. However I need to point out us impoverished Northeners are somewhat restricted to the amount of space we can devote to our toys. Mine is in the living room ! I do what I can with the tools i have. As many a man would say you can only bleep with the bleep you've got  Who has the right to judge a man for the clothes he wears or the way he talks ! I cant review it however as I've never run such a small lathe before but it is an attractive wee thing and nice to look at. While others might overlook such a fine wee machine. I think they do so in error. For 'from acorns mighty oaks grow' after all.

Who has the right to judge a man for the clothes he wears or the way he talks ! I cant review it however as I've never run such a small lathe before but it is an attractive wee thing and nice to look at. While others might overlook such a fine wee machine. I think they do so in error. For 'from acorns mighty oaks grow' after all.

Im sorry everyone I do go on sometimes. I only wanted some pictures of Countershafts :/

>< LOL

Meanwhile if anyone is still reading this theres a really Funny new South Park esk Cartoon Series available to watch on You Tube. Its about Mining in Australia. Anyone that likes southpark humour should check it out but only if your over 18 and out of nappies. I wont link you too it but its very much in the vein of south park and perhaps made by the same two funny lads that did southpark ! Anyway its called Mining Boom. A funny and healthy look at Work and … well you just need to watch it. Its not totally offensive but fairly close and ticks just about every box that it could without crossing the line. My line at least ! I don't think it has a PG rating or 18+ for that matter but there is a warning before you watch it. If your sensitive at all about well almost anything really, then you should probably not watch it.

OK I'm done, i'm off to play with Autocad now. And maybe get another cuppa tea. and a chocki biscuit. Hmmm

Paul

oldvelo.

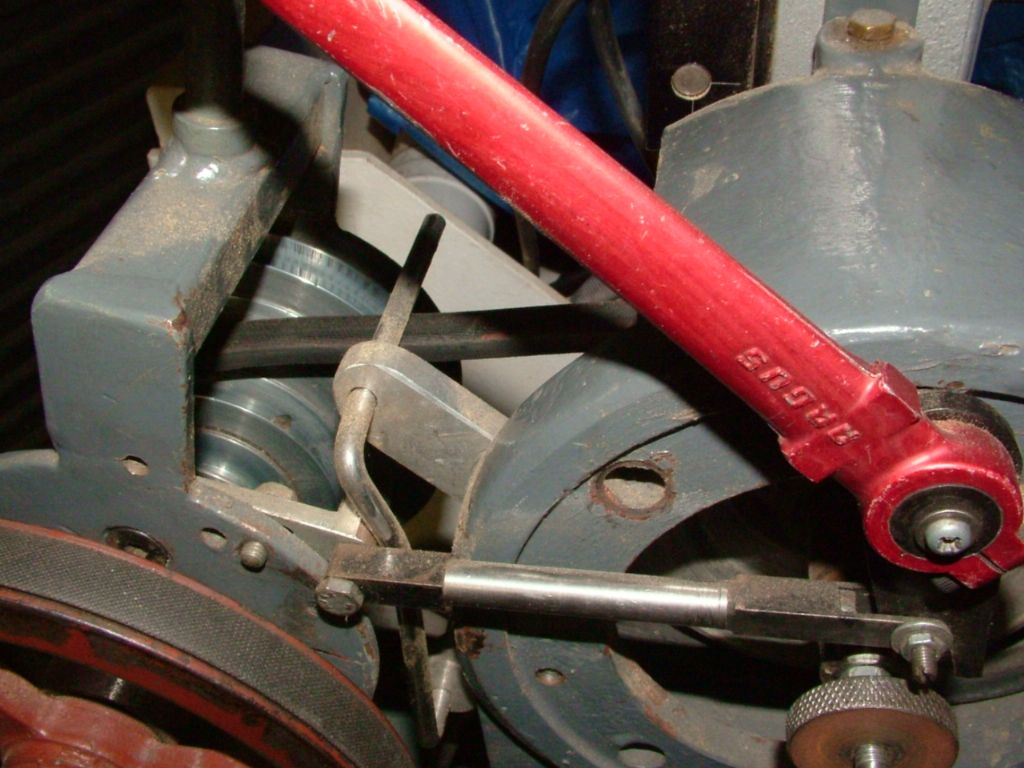

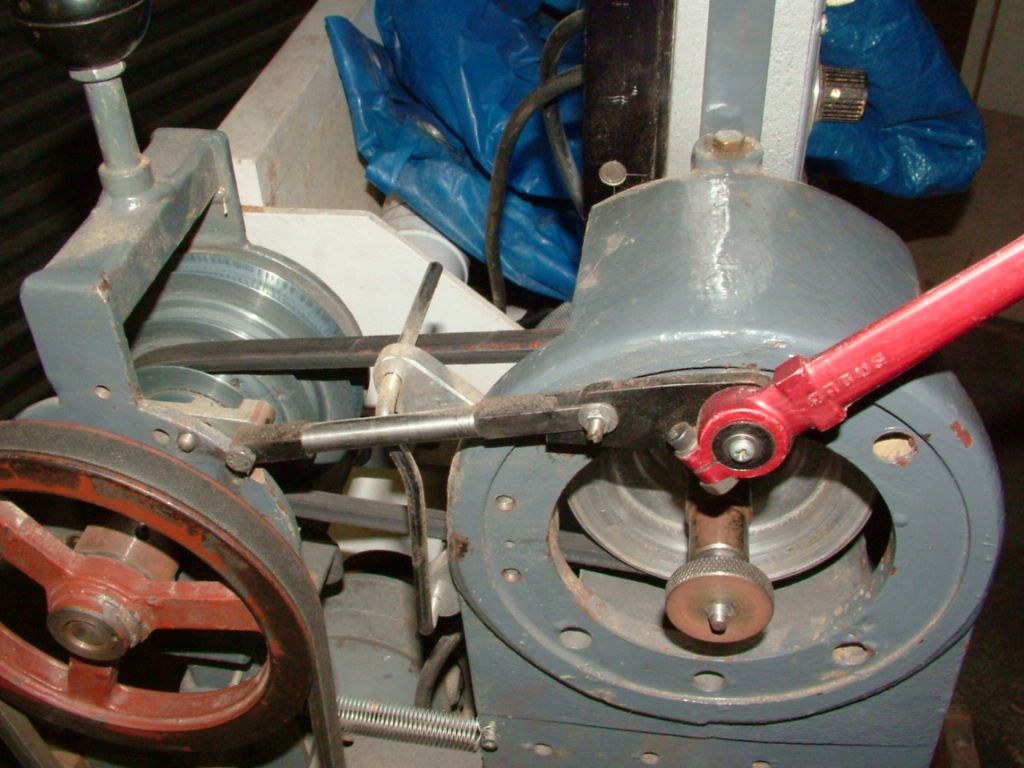

SO That being said, i'm very keen to get cracking and build one. I've been thinking it out in my head and made one or two sketches of the original bench mounted design. What i'm planning is welding up steel plate, angle iron, flat bar and round bar to make the frame and base. And then machine it. Easier said than done but it shouldn't be too difficult given the right tools. I think I have most of the main tooling i require but there's always something you miss.Im really lacking actual workspace and might have to wait untill the spring summer or at least untill i get some dry weather and try tackling it outside in the carpark or the green. No welding bench either so it will have to be a plate of steel on a B&D Workmate Workbench ! I'm also looking for better photos for a start so i can import them into autocad and then scale them correctly with a known size so i can generate reasonably accurate plans compared to the original bench countershaft. So i'm playing myself at this point but thinking and planning don't cost me any cash so.

SO That being said, i'm very keen to get cracking and build one. I've been thinking it out in my head and made one or two sketches of the original bench mounted design. What i'm planning is welding up steel plate, angle iron, flat bar and round bar to make the frame and base. And then machine it. Easier said than done but it shouldn't be too difficult given the right tools. I think I have most of the main tooling i require but there's always something you miss.Im really lacking actual workspace and might have to wait untill the spring summer or at least untill i get some dry weather and try tackling it outside in the carpark or the green. No welding bench either so it will have to be a plate of steel on a B&D Workmate Workbench ! I'm also looking for better photos for a start so i can import them into autocad and then scale them correctly with a known size so i can generate reasonably accurate plans compared to the original bench countershaft. So i'm playing myself at this point but thinking and planning don't cost me any cash so.