I've put it all back together last night, and she runs again,  much smoother and heaps quieter… I also got a maybe another 1000 rpm by fitting a new belt; the old one was worn to 34mm high as opposed to 38mm…

much smoother and heaps quieter… I also got a maybe another 1000 rpm by fitting a new belt; the old one was worn to 34mm high as opposed to 38mm…

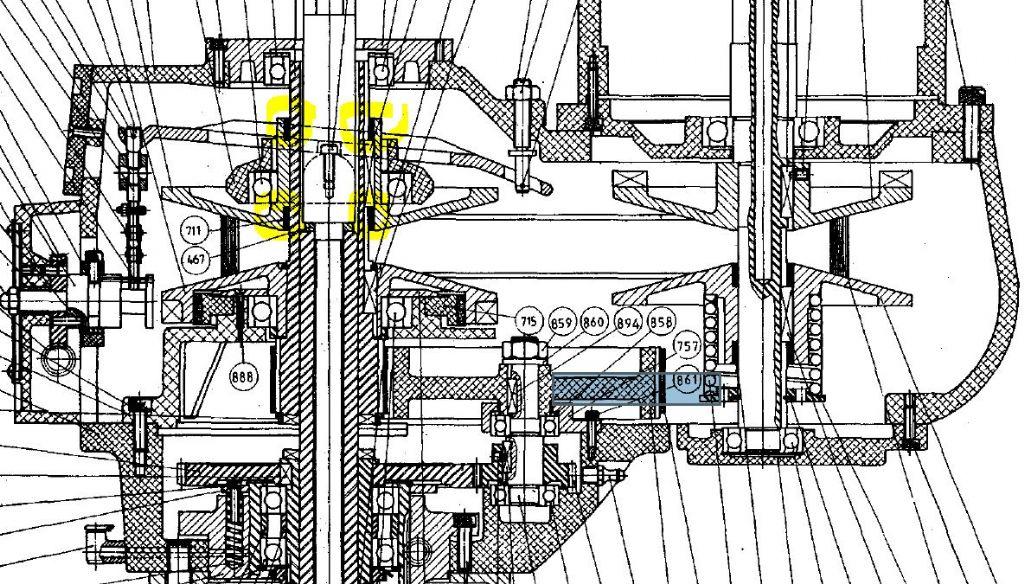

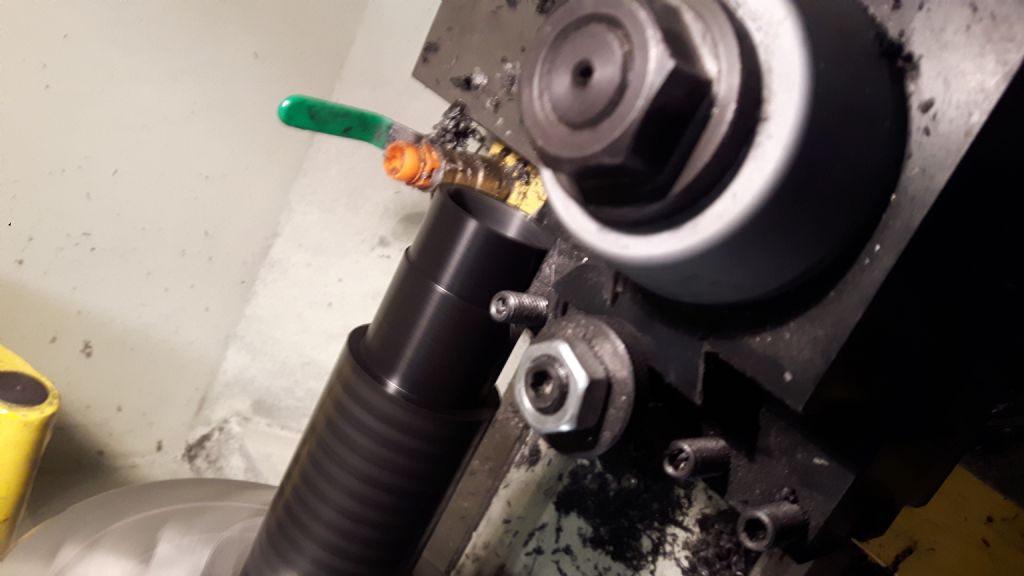

I bought a piece of 2" acetal from ebay, and used a very positive rake CCGT 09T304 NF25 tool to cut the acetal, it was surprisingly easy to machine and get a great finish; though as Clive said you have to wait a few seconds for it to cool down before final measuring. Made both bushes from a 6" length + one scrap one which I broke when sawing out the keyway.Keys were a couple of bits of Brass as that's what the manufacters now supply.. All glued together with loctite 638 after several de-greasings

It had the advantage that I could make the bushes and keys to the current size of the shafts,and longer to spanover the "scuff" on the pulley shaft; i was worried that fitting manufacturers bushes to the worn shafts would lead to accelerated failure of the new bushes.

I gained some experience in working with acetal and probably spent a day making/fitting bushes and keys; the rest was another day or two strip down, cleaning and lubricating the whole machine.

if (when) it fails again I will add 3 step pulleys and a simple V belt,and use my inverter for the steps in between.

Total cost less than £20 as opposed to £302.40. I did spend another £95 on a new belt but I would have had to do that anyway.

Thanks for the advice; it really helps to have this forum around.

Mark Simpson 1.