Many thanks to everyone who has replied.

The replies have helped me to see what is critical and what isn't. There seems to be a consensus, starting with Rod, on a slight downwards tilt at the holding end. This is the practice I've always followed with the clamping kits I've got, so I suppose there's no reason for vice clamps to be any different.

Clive, I do have a paper gasket between my adjustable angle plate and the table, but I didn't put one in when I installed my vice; I will do so when it next gets moved. I didn't know aluminium was a preferable material for table clamps, though I see the logic of it. Presumably the ubiquitous clamp sets in the £40-£60 range would be prohibitively expensive if aluminium was used. I haven't got any aluminium of a suitable size at the moment but I do have a two foot long piece of inch square brass. I suppose using that would be extravagant, though.

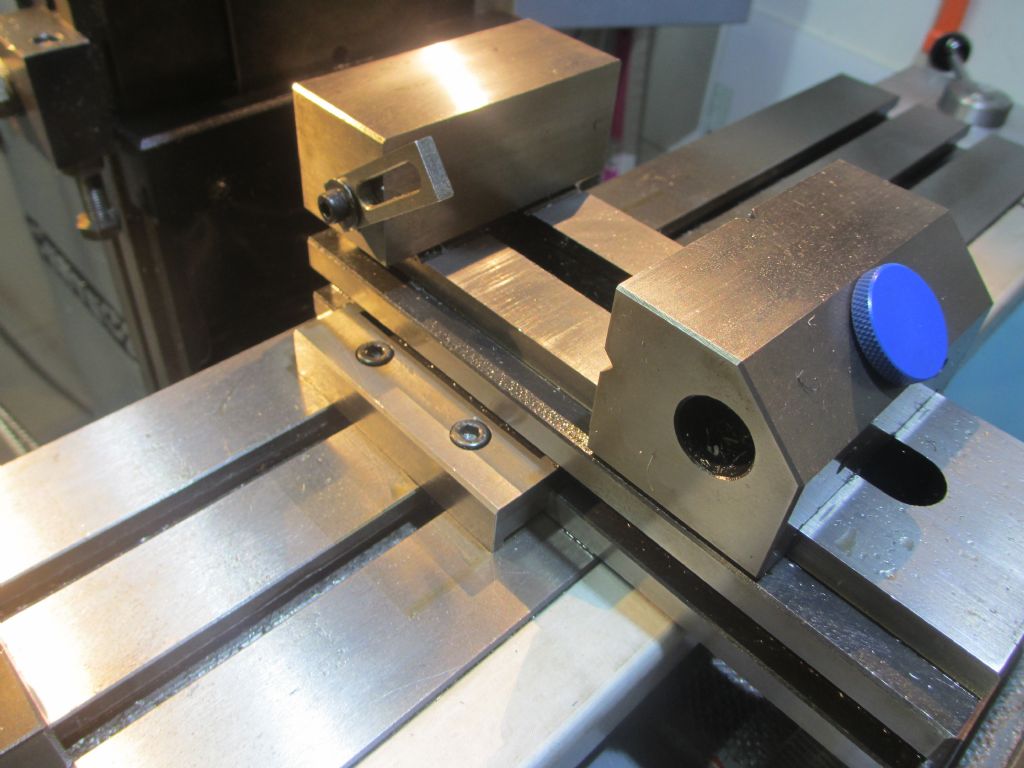

John, your solution is very interesting. I might want to put a flat on the side of the rod in contact with the table, but your experience suggests that's not strictly necessary.

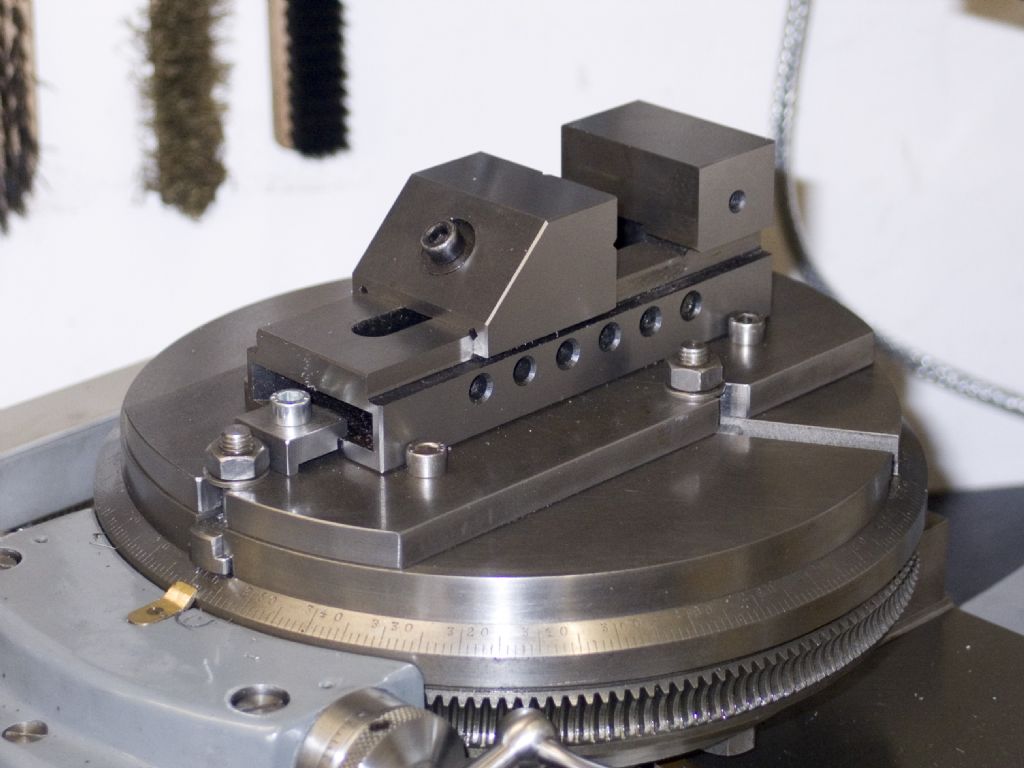

Phil, your base is very elegant and no doubt a big time saver when the vice needs to be re-installed. I note your point about hex head screws being preferable for not acting as swarf traps.

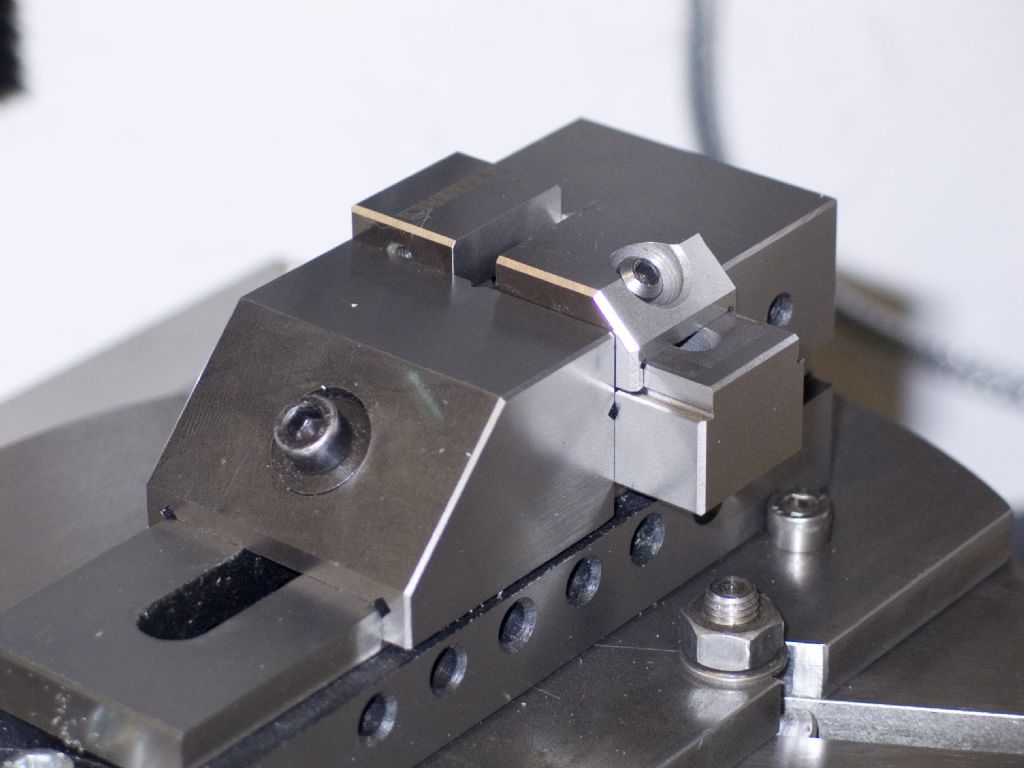

T.B., your end clamps are a great idea. Could you give me the dimensions? Having the dimensions would be very useful even if I ultimately make a different kind of clamp.

John Reese.