Posted by Mick B1 on 20/01/2020 14:45:00:

Posted by SillyOldDuffer on 20/01/2020 11:02:09:

…

Can't agree with Mick's suggestion the cause is 'inclusions of different steel types in a cheap gash melt', because it implies steel is made haphazardly in small quantities.

…

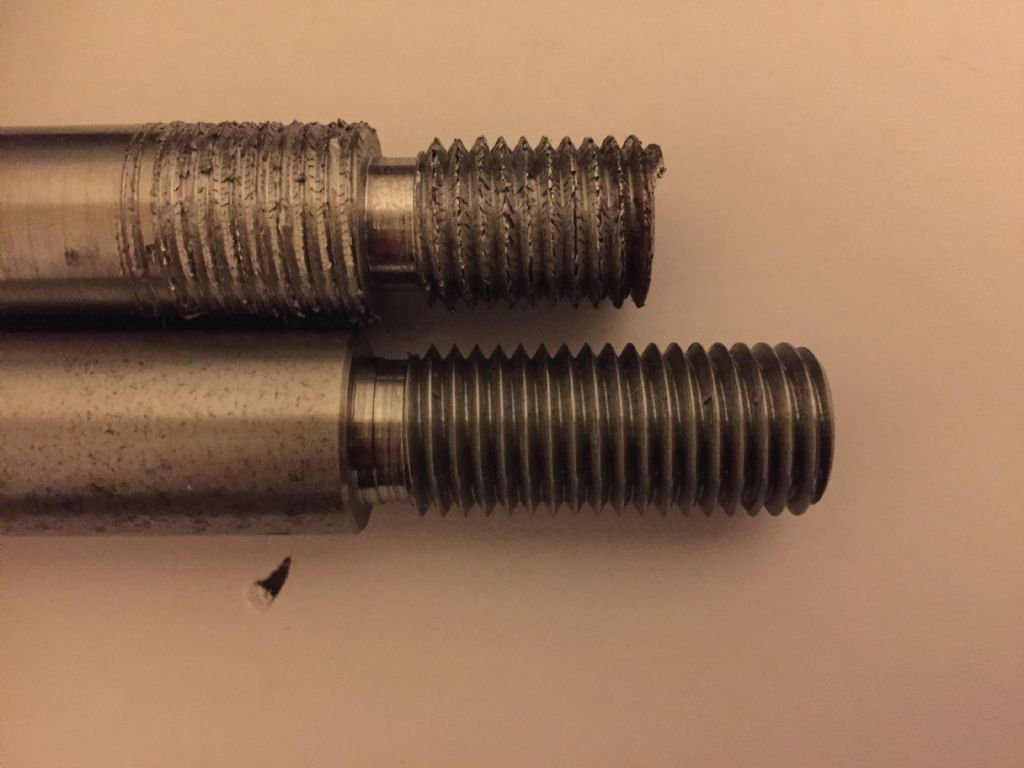

SOD:- Well, it was a long time ago, but I can remember prising out bits that looked a lot like broken gear teeth from a bit of what'd been held in RM stores as EN3B, that I was trying to turn. Describing the proper processing doesn't mean it always gets followed.

…

Maybe, it might have been made in a British Furnace like this, first built in 1711 and closed after various upgrades in 1966, long after it was obsolete:

Picture Attribition Wikipedia: The photo is of a small manual producer, not very scientific, with quality depending mostly on the skill of the individuals operating it. Capable of good results, but not when the skilled operator is drunk, ill or on holiday! Or his boss insists on cutting corners. This sort of 'stirring scrap in a pot' operation may be what chaps imagine goes on in the Far East. Very unlikely!

Far more typical of modern steel-making is the British Steel plant at Scunthorpe:

Plants like this are highly mechanised, highly efficient, with most sources of human error removed. This is the sort of operation unlikely to make steel containing unmelted inclusions, or steel outside the target specification.

Sadly the Scunthorpe Steelworks was sold for £1 in 2016 and went into receivership, bankrupt, last year. Nothing wrong with quality, the problem was cost. This relatively small steelworks relying heavily on imported materials and an expensive workforce, couldn't compete with the really big boys. No profit in it.

To give an idea of scale, 1,808,000,000 tons of steel were made in the world during 2018. China made 928,300,000 tons of it, and the second largest producer was the European Union, at 168,200,000 tons. In 2018, the entire British steel output was 7,700,000 tons, or 0.43% of the world total, slightly less than Egypt. Of course quantity isn't everything, in 2020 steel made in Britain will be something special, high-quality, made in an electric furnace for very demanding applications.

China's dominance of steel isn't entirely wonderful for them because the market for steel is ferociously competitive and very vulnerable to sudden drops in demand. Large inflexible enterprises catch bad colds : about 2 million Chinese steel workers have been made redundant since 2018, which makes British job losses in the steel sector look like chicken-feed, agonizing though they were. (In the UK, about 250,000 lost jobs since 1967, or roughly 50 years). Change in the steel industry, wherever it happens to be located in the world, can occur quickly. British steel production peaked in April 1970 at nearly 2.9 Million tons, but collapsed to 0.13 Million tons in February 1980.

It's not that I believe inclusions are impossible, only that modern steel production methods make them far less likely than in the past. Can anyone post a photo of a recognisable inclusion found by them in a bit of modern metal? Slag is far more likely than ball bearings and gears!

Dave

SillyOldDuffer.