Posted by Russell Eberhardt on 15/11/2015 20:08:51:

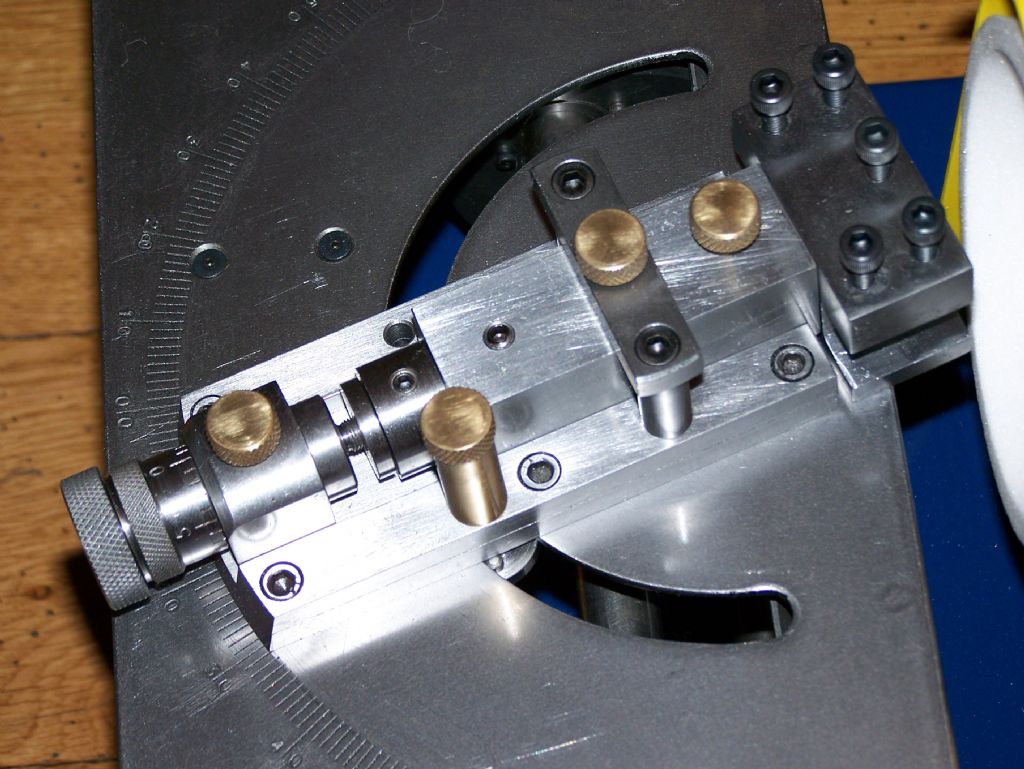

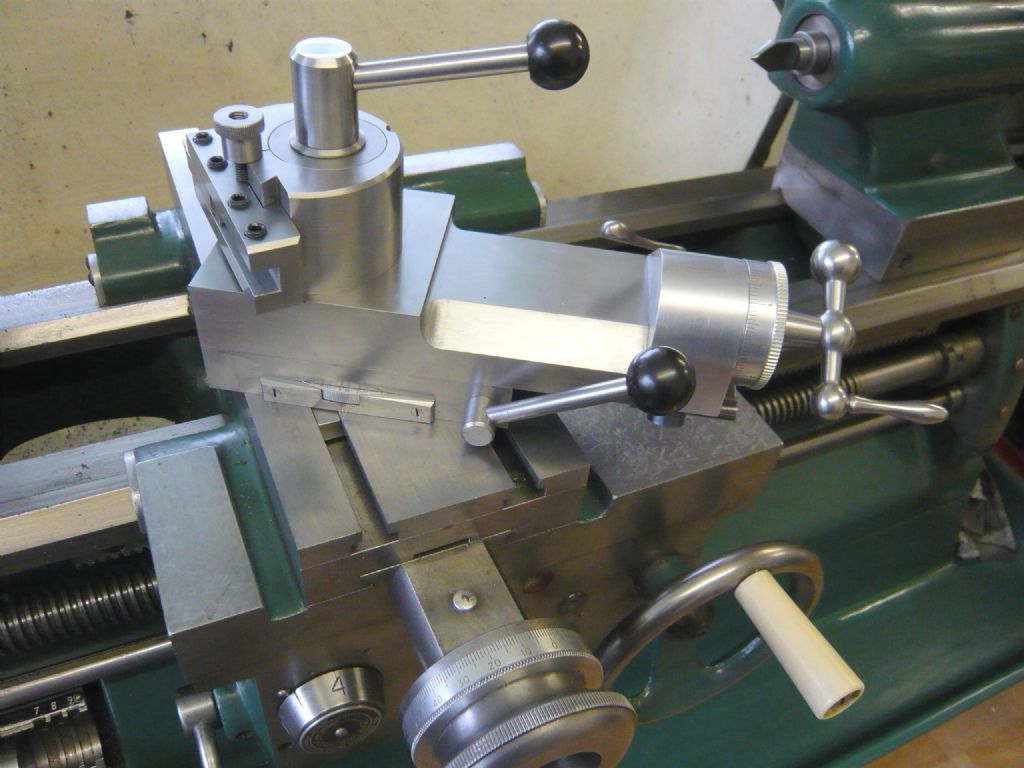

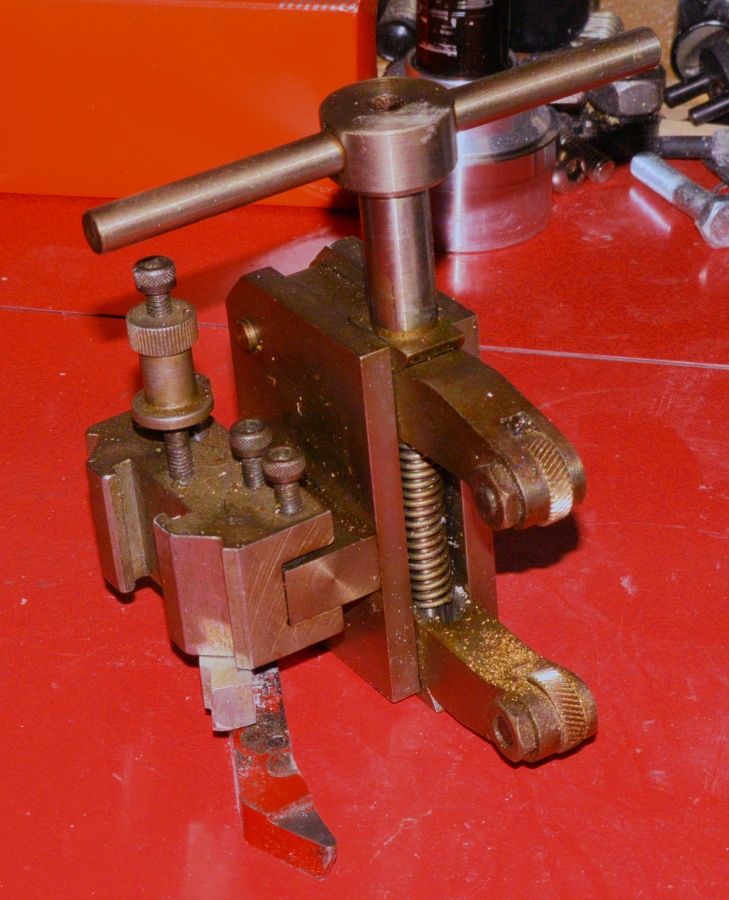

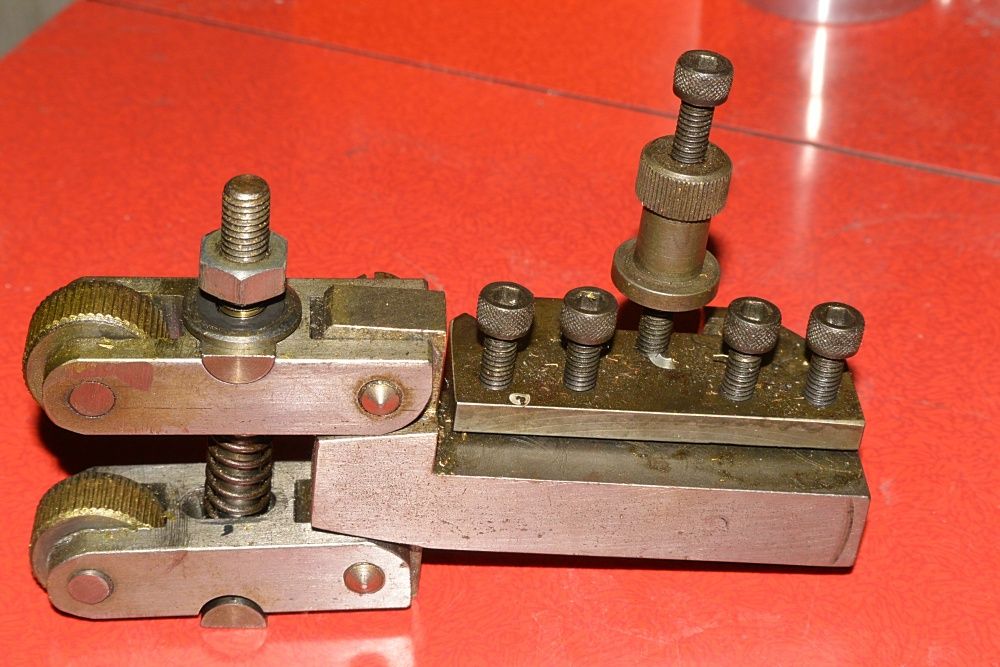

The most useful tool I've made is a QCTP to a design by J.S. published on the net about 12 years ago!

Russell.

.

Try 21 years ago, around 1994 according to the drawings.

However the original article was in ME in 1989.

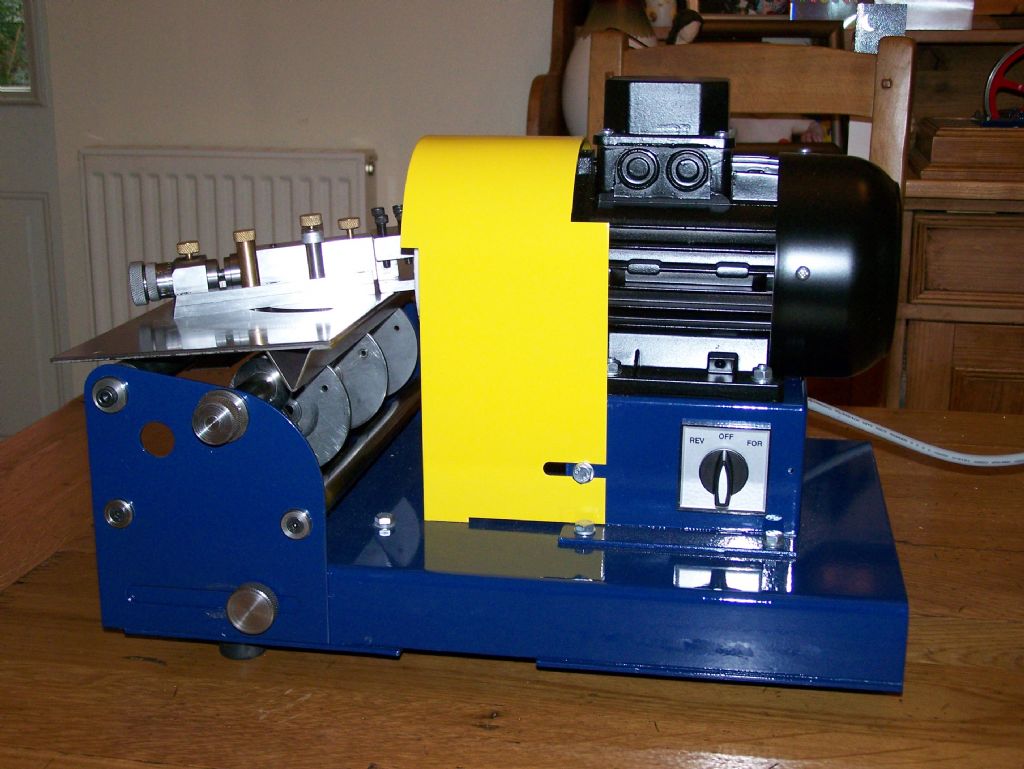

I'd be hard pressed to pick one tool but one I use daily is the tapping head I built.

But last year I converted it from air to electric so I wouldn't have to run the big compressor for doing just a few holes.

I didn't want to mess with the air unit in case it didn't work so I canabilised an unused Machine Mart air drill for the epicyclic reduction box.

It's a three phase motor running off an inverter which gives me variable speed plus instant reverse. Still uses the clutches off the air unit so you can tap a blind hole and it just slips when it bottoms out.

Now can use it for just one hole and being bench mounted it's within reach of the vise so every hole is square.

Edited By John Stevenson on 15/11/2015 20:48:19

mechman48.

My fc stainless generally seems to be a ferritic grade. I just ask for free cutting and one lot wasn't so I'd guess that's why.

My fc stainless generally seems to be a ferritic grade. I just ask for free cutting and one lot wasn't so I'd guess that's why.