Thank you Bill!

It does work as the rubric in " – better-English-than-my-Mandarin – " promises, I take it?

'

What did I do today?

| had a rest from smothering the Harrison L5 lathe in oily swarf, by going caving.

'

Why oily swarf in lathe-burying heaps? I'd spent much of the week making the boiler / smokebox ring for my steam-wagon. I think there was more metalwork in setting it up than making it, by trepanning it from a piece of well-weathered 15mm steel plate.

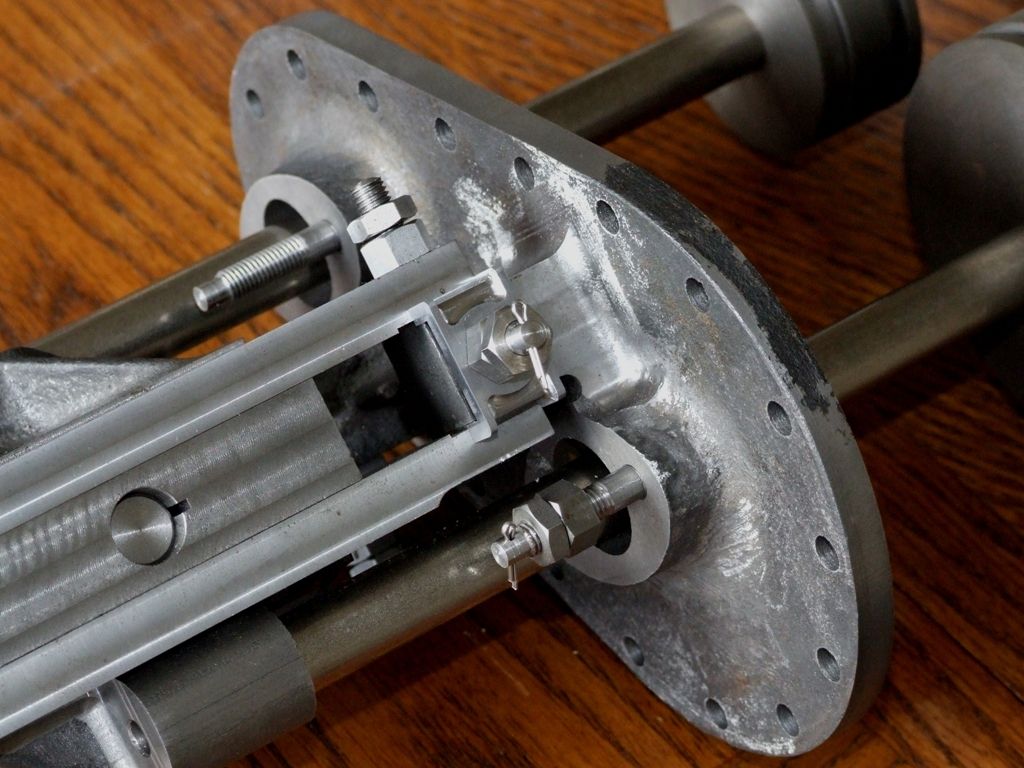

It is a ring 8" od X 6.4" id, with most of it turned away to form an annular channel :

Take one such plate, some 16" square; verify that a central recess already faced in it would not foul the intended bore. Wire-brush in angle-grinder to remove the worst "weathering". Oh, first – see my post above – find an old angle-grinder spanner, un-pin it and file it to fit the brush-nut.

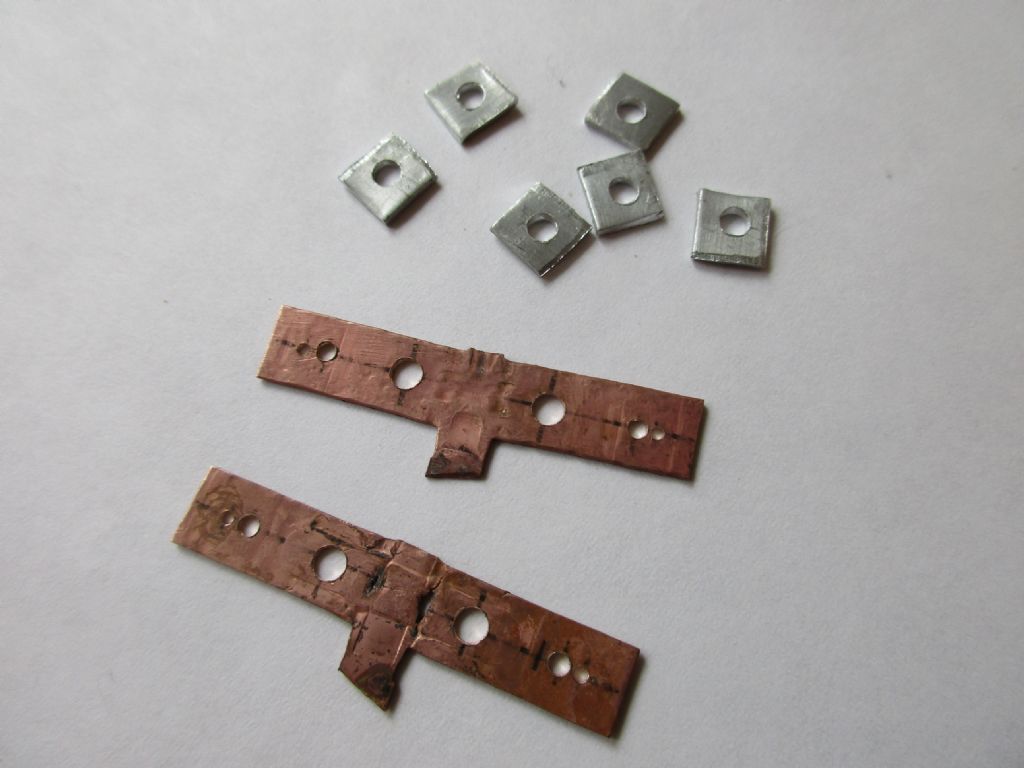

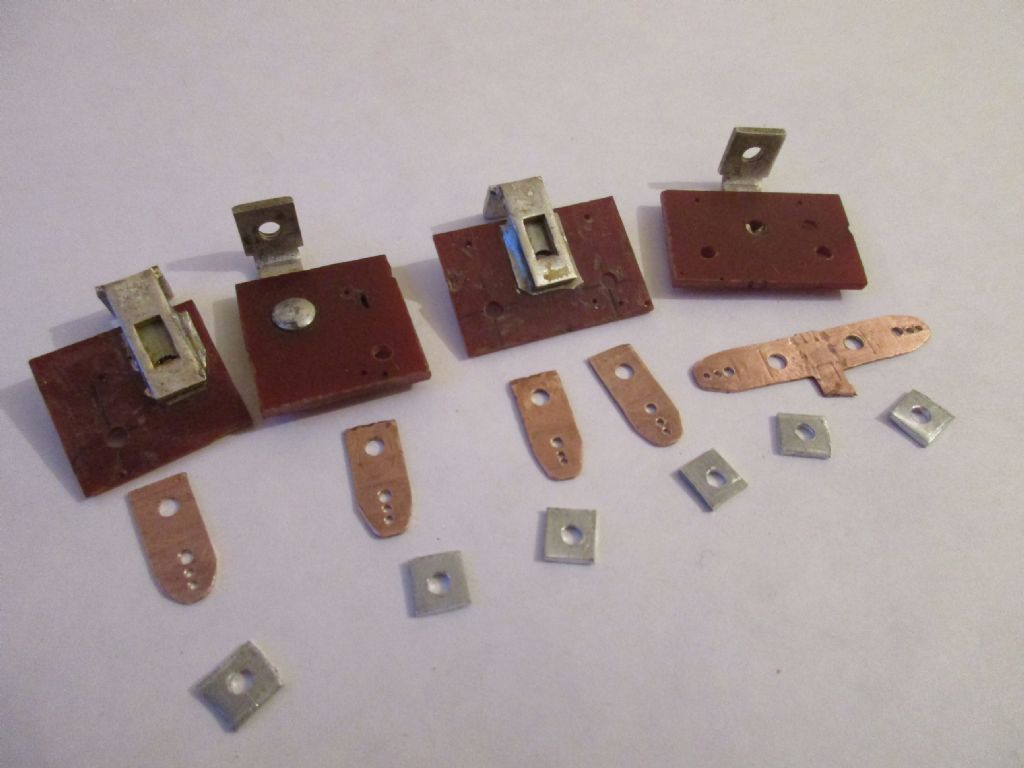

Decided on the threaded plugs for 4 holes already in the stock plate, and slap on the centre-circle of the channel. They had been 1/2" dia clamping-holes for turning that recess. The bushes, intended as permanent, could only be 9/16" dia over threads, and a fine thread at that. Luckily I have a 9/16" UNF tap and die. Also tapped them M6 right through.

Screwed them in, with Loctite.

Worked out the order: trepan outside off first, then the channel, then the ring from the centre disc. Measured face-plate (<<16" dia.). Removed "splash-back" from the shelf above and behind the lathe, as it fouled the plate.

Assessed potential disasters if the appropriate bits are not secured when cut through… A 16" square of 15mm plate on a 9" faceplate revolving at perhaps 60rpm, is rather alarming!

I had thought to put the lathe motor controller above the tail, well away from the moving parts. The L5 has a clutch lever over the headstock but I was NOT going anywhere near a revolving work-piece like that, so left the clutch engaged and turned the machine on with the tool well clear. (In lowest gear.)

Machined (on the Myford) a bush to fit the spindle-nose and the plate's central hole. This was sort of helped by some philistine in the past having bored out the first inch of spindle taper to summat around 1.3"-ish with a rough finish, but cylindrical. Ish.

Cut some M6 studding pieces – fitted these to the UNF plugs. (Also permanent but yet to be trimmed flush.)

Cut 4 pieces of 3/8"BSW studding (compatible with my commercially-made clamping-sets); to fit holes already near the plate corners, to take angle-steel clamping-bars. Drill & tap the plate just shy of the faceplate rim for M8 set-screws and large washers as further restraints.

More tea.

More studs and tappings for the inner disc.

Assembled all, using plastic building shims as sacrificial spacers between work-piece and faceplate. Removed gap-filler. Assembled to lathe, with the spindle bush as locator to ensure the plugs' pitch-circle and the channel would match correctly. Secure this bush (too large to pass through the faceplate) with long studs and joiners from the clamping-set, right through the spindle.

Discovered the saddle would not approach the work without running off the rack! Ho-hum. Pushed it into place, tested top-fee range, stud clearances &c. Used tailstock as back-stop. Ground a trepanning cutter.

More tea. Used the Radio Times to select suitable background soothing from the workshop wireless.

Cut off the outer. That alone took well over two hours! Back-gear, lowest range-gear, motor happy at about 900 rpm in the green sector on the Newton-Tesla 3ph controller. Lots of brushed-on suds.

Oh the relief when rust-dust and blue plastic finally emerged from the cut, and nothing moved as shouldn't!

'

Switched all off and went indoors for tea… rather late tea.

Friday afternoon: unscrewed the newly-made steel commode-seat from face-plate, put it to one side. Re-fitted the gap-piece.

'

Mug of tea? No: a pleasant half-hour of tea and cake in a nearby café run by a former soldier as a mutual-support place for ex-Services personnel, but with opening-hours for all, including we civvies, too. One day and one evening are for veterans only, as are a private garden and gym out the back.

'

Back to it. Had to renew the tool again (dig-in, BANG! "Bother", or words to that effect). Carved out the channel. I'd made the plugs and their studs full-depth to minimise the interrupted cut, but there was still some thumpety-thump.

Finally parted the channel from the central disc; each still held by their respective M6 and 3/8BSW studs and nuts.

Quick test: yes the ring fits both boiler and smokebox! Rather freely but not excessively: not bad considering I have no Vernier or digital calipers to this size so had to use the traditional firm-joint calipers and steel rule.

Rang down "All Stop". Mid-gear, brakes on…

Retired for tea, 9pm.

Nigel Graham 2.